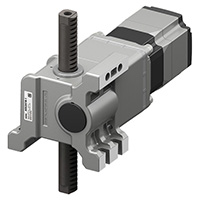

Rack and Pinion System L Series - AZ Series Equipped

Linear Head Rack and Pinion System LJ Series - αSTEP AZ Series Compatible

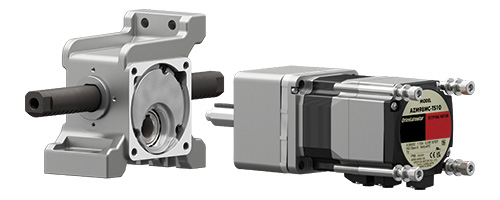

When the LJ linear head with rack and pinion mechanism is attached to a parallel shaft gearhead and motor, linear motion such as pushing, pulling, raising and lowering is possible. Perfect for high load or long stroke applications. Use with the AZ Series that utilizes a battery-free absolute sensor, which allows for high positioning accuracy and high load transportation.

- Horizontal or Vertical movement

- 200 kg Maximum Transportable Mass

- Electromagnetic Brake options

- AZ Series Driver required*

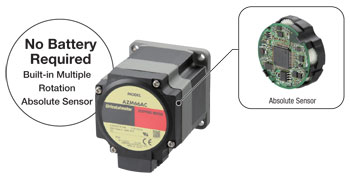

Mechanical Absolute Encoder

Product Lineup

Driver Power Input |

Actuator |

Options |

Max. Trans. Mass |

Max. Speed |

Stroke |

AC Input |

Electromagnetic Brake |

200* |

500 |

100 ~ 700 |

*Max. Vertical Transportable Mass varies by Rack Length.

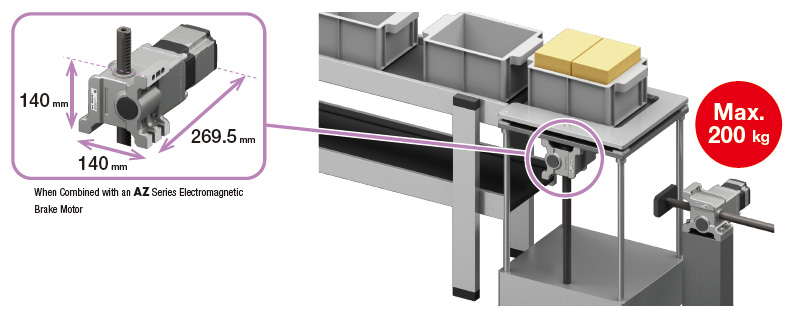

A Maximum Transportable Mass of 200 kg in a Compact Size

200 kg Maximum Transportable Mass*

Large-diameter pinions and stronger gears enable a maximum transportable mass of 200 kg*

*The maximum transportable mass depends on the gearhead's gear ratio and combined motor.

700 mm Maximum Stroke Length

Product line with strokes from 100 to 700 mm

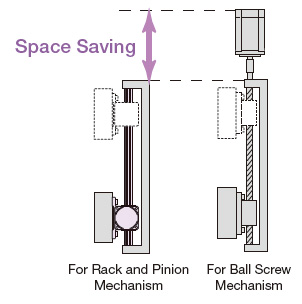

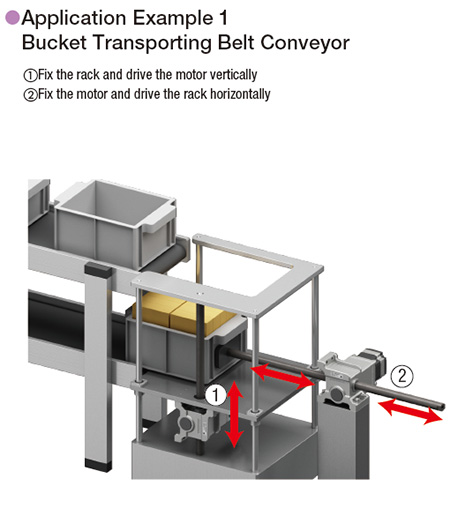

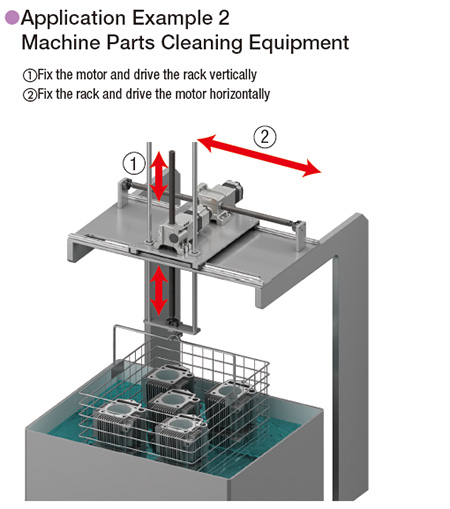

Fix the Rack for Effective Use of Space

The motor itself can run on its own by fixing both ends of the rack. It is effective for equipment where motor space is difficult to secure.

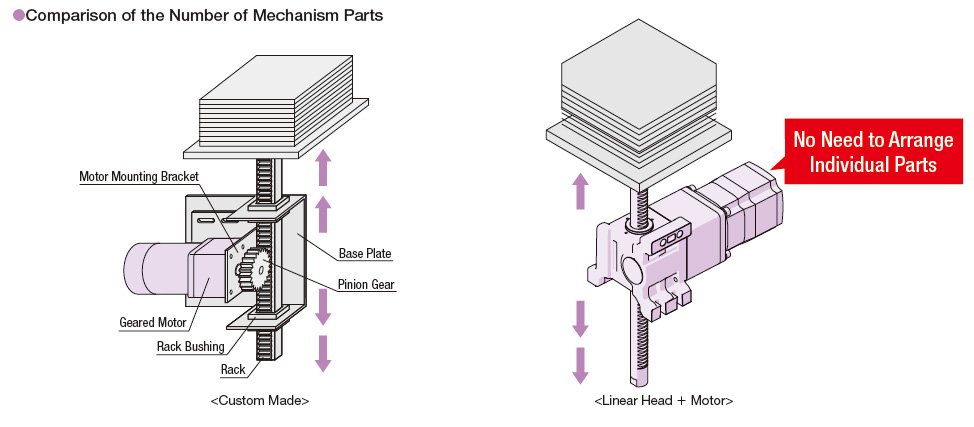

Contributes to Improved Design Efficiency

Reduces Time from Design to Startup

Compared to a self-built rack and pinion mechanism, the number of parts is reduced, the amount of labor for design and assembly can be reduced.

Easy Assembly with a Parallel Shaft Gearhead

The stucture is simple. Just insert a parallel shaft gearhead into the linear head and fix it with screws. This makes both installing to the equipment and performing motor maintenance easy.

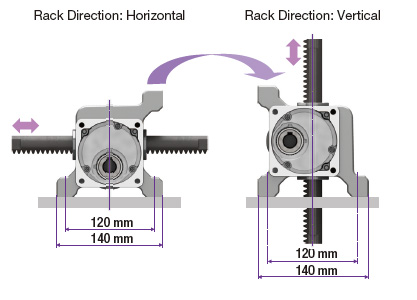

Rack Can be Installed in Horizontal or Vertical Orientations

The structure allows for mounting in both horizontal and vertical directions. The ability to freely select mounting direction contributes to improved ease of design and cost reductions through the sharing of parts.

Applications

The rack and pinion mechanism, which can be used in a variety of applications, is a product that can be selected just like a component, and is easy to use.

Absolute System Equipped with the αSTEP AZ Series Hybrid Control System

No Home Sensor Required

Oriental Motor has developed and patented a compact, low-cost, battery-free mechanical type absolute sensor. The αSTEP AZ Series is available at affordable prices and can contribute to improved productivity and cost reductions.

Because it is an absolute system, no home sensor is required.

High-Speed Return-to-Home Operation

Because return-to-home is possible without using a home sensor, return-to-home can be performed at high speed without taking the specifications for sensor sensitivity into account, allowing for a shortened machine cycle.

Reduced Cost

Sensor and wiring costs can be reduced, allowing for lower system costs.

Simple Wiring

Wiring is simplified, and the degree of freedom for equipment design is increased.

Not Affected by Sensor Malfunctions

No need to worry about sensor malfunctions, sensor damage or sensor disconnection.

Improved Return-to-Home Accuracy

Home position accuracy is increased because the return-to-home action is performed regardless of any variations in home sensor sensitivity.

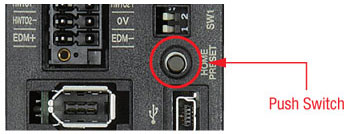

Easy Home Position Setting

The home position can be easily set by pressing a switch on the front of the driver, which is saved by the absolute sensor. In addition, home setting is possible with the MEXE02 support software or by using an external input signal.

*Requires AZ Series Driver

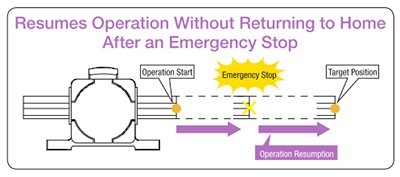

Return-to-Home Not Required (Built-in Controller Type Driver)

If the power shuts down during a positioning operation, the positioning information is retained. Furthermore, for built-in controller types, positioning operations can restart without a return-to-home when recovering from an emergency stop or a blackout.

Battery-Free

No battery is required because it is a mechanical-type sensor. Because positioning information is managed mechanically by the absolute sensor, the positioning information can be preserved, even if the power turns off, or if the cable between the motor and the driver are disconnected.

Reduced Maintenance

Because there's no battery that needs replacing, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control box.

Safe for Overseas Shipping

With normal batteries that self-discharge, care must be taken when the equipment requires a long shipping time, such as when being sent overseas. The absolute sensor does not require a battery, so there is no limit to how long the positioning information is maintained. In addition, there's no need to worry about various safety regulations, which must be taken into consideration when shipping a battery overseas.

Position Holding Even When the Cable Between the Motor and Driver is Detached

Positioning information is stored within the absolute sensor.

Electromagnetic Brake

These products have built-in power-off activated electromagnetic brakes. When power is accidentally cut off due to a blackout or other unexpected events, the electromagnetic brake holds the load in position to prevent it from dropping or moving. Also, when the motor is at standstill, it can be held by the electromagnetic brake. It is possible to suppress the heat generated from the motor by turning off the motor current.

AZ Series AC Input Drivers

The αSTEP AZD (AC Input) Drivers offers superior high speed performance, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. Advanced operation and function control is included through our MEXE02 software (free download). The αSTEP AZD (AC Input) Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Emergency Torque Off Function

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with αSTEP AZ Series Motors (AC Input)

![]()

Connection Cables (required)

The motor cable and electromagnetic brake cable from the motor cannot be connected directly to the driver. When connecting to a driver, use a connection cable.

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Dog

Dog for Linear Actuator

Rotary Encoders

Small, thin, and lightweight stand-alone rotary encoders with an outer diameter of ϕ30 mm can be installed in tight spaces.

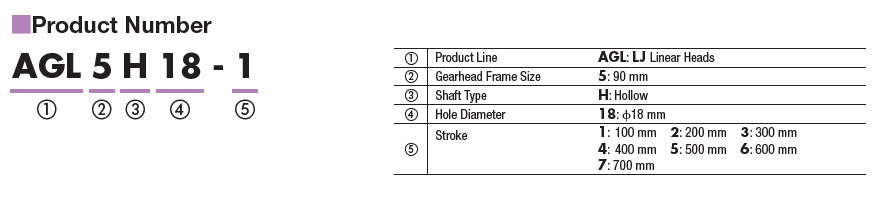

Product Number Code

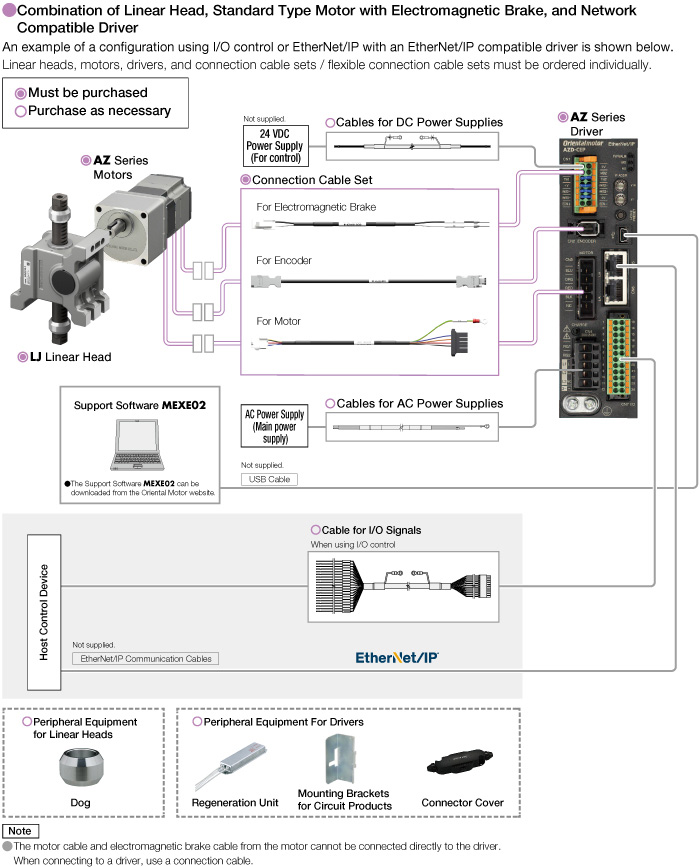

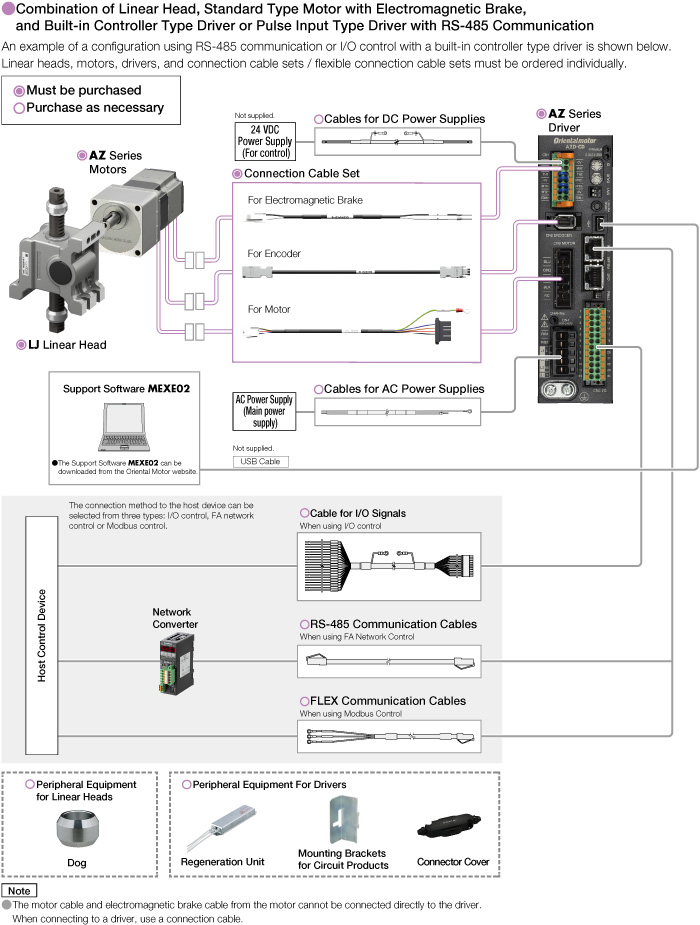

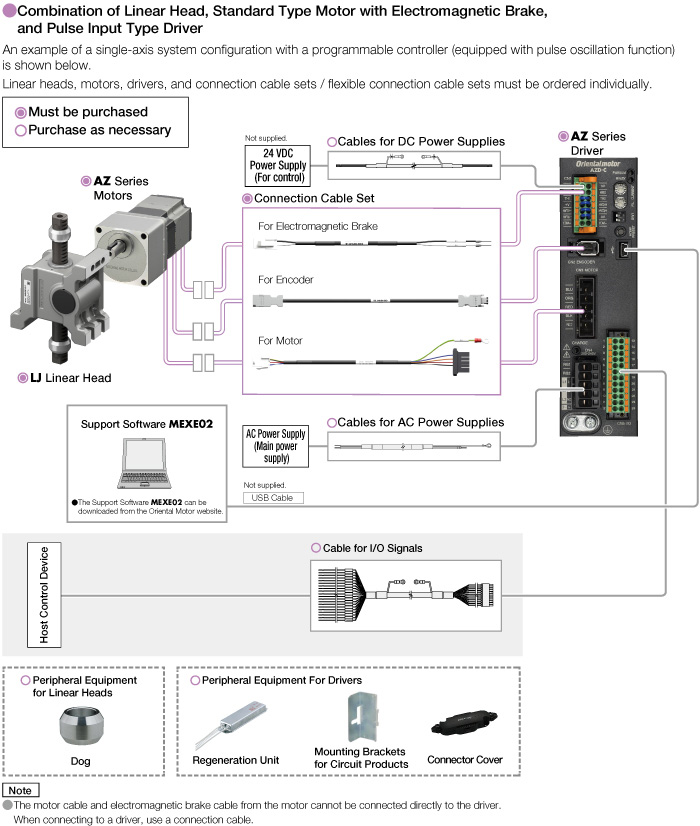

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.