Guide to Carbon Neutrality: Getting Started

Environmental considerations related to automation are attracting more attention as major nations announce carbon neutrality policies.

Check out our products and services with hints about getting started with carbon neutrality.

Starting with Energy Saving Motors |

Starting with Control Cabinets |

New Equipment Design Considerations |

Think about how to use the product |

Choose the most suitable product |

Need some help? |

Starting with Energy Saving Motors

Using an energy saving motor in transport, agitation, winding, and other forms of speed regulation can reduce CO2 emissions by lowering the power consumption. Brushless motors are small, high-efficiency speed control motors with an on-board sensor and a dedicated circuit (driver) that performs feedback control.

The Effects of Using a Brushless DC Motor

Annual power consumption (compared with output 60W)

|

Power consumption |

CO2 Emissions |

Electricity |

|---|---|---|---|

AC motor |

439.2 |

228 (503) |

$53.64 |

Brushless DC Motor |

273.6 |

142 (313) |

$33.41 |

- Calculated at 12 hours of drive time per day, 300 operating days per year, a power–CO2 emissions conversion coefficient of 0.519 kg–CO2/kWh (1.144 lb–CO2/kWh), and electric utility rate of 0.12 USD/kWh

- The usage conditions are as follows; AC motor: output 60W , Single-phase 200V, 60HZ brushless motor: BMU series, output 60W

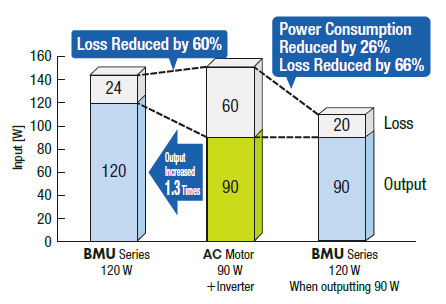

More Efficient than Inverter Control

Brushless motors use permanent magnets in the rotor, suppressing rotor secondary loss. This results in a roughly 26% reduction in power consumption compared to a three-phase induction motor for inverter control*. This helps the equipment to save energy.

* When Output Power is 90 W

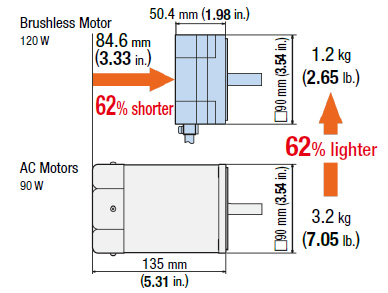

A Smaller, Lighter Motor Means Fewer Natural Resources

Brushless motors with built-in permanent magnets are both slim and high-power. For example, compared to a three-phase induction motor of frame size 90 mm, their total length is 84.6 mm shorter. This contributes to equipment downsizing and the use of fewer natural resources.

Compatible Products

A huge variety of motors is available, from ones that offer easy speed adjustment with a dial to ones that offer position control and network control. Select the motor that best suits the application at hand. Compatible Products

Starting with Control Cabinets

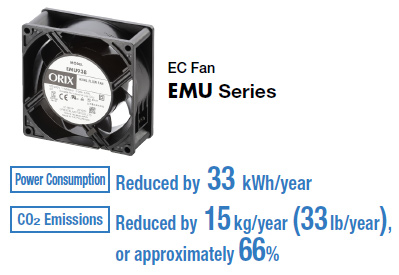

Reduced Power Consumption with an EC Fan

Cooling fans offer adequate ventilation and air flow for the forced-air cooling of control cabinet heat sources. The EMU Series of EC fan achieves reduced power consumption through the use of a built-in brushless motor. With a long expected life of 60,000 hours, approximately 2.2 times longer than the conventional product, this also means fewer natural resources are consumed.

The Effects of Using the EMU Series

Annual Power Consumption (Compared at a frame size of 120 mm)

|

Power consumption |

CO2 Emissions |

Electricity |

|---|---|---|---|

Conventional Product |

49.9 |

22.6 (49.8) |

$7.88 |

EMU Series |

16.9 |

7.6 (16.8) |

$2.66 |

- Calculated at 16 hours of drive time per day, 240 operating days per year, a power–CO2 emissions conversion coefficient of 0.453 kg–CO2/kWh (1.00 lb–CO2/kWh),

and electric utility rate of 0.16 USD/kWh - Comparison of EMU1238 and MU1238A-11B

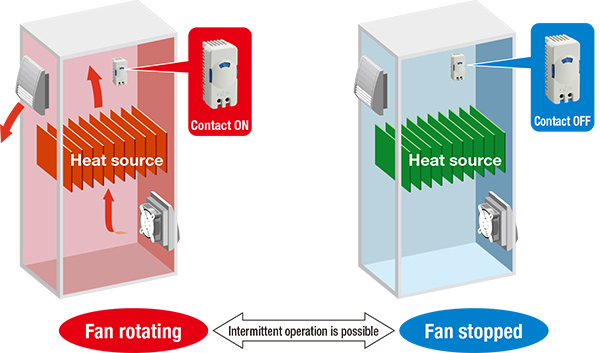

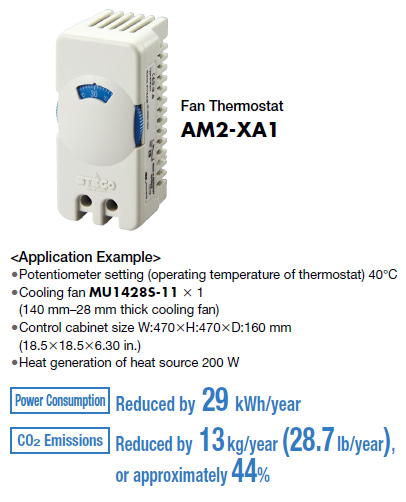

Use of a Thermostat to Cool Only When Necessary

By combining the cooling fan that is already in the control cabinet with a thermostat, cooling becomes more efficient. This will stop the cooling fan when the enclosure is already cool, reducing the power consumption from the fan.

The Effects of Using a Thermostat

■Reaches set temperature |

■Control cabinet cooled |

Annual Power Consumption (Compared at a frame size of 120 mm)

|

Power consumption |

CO2 Emissions |

Electricity |

|---|---|---|---|

Cooling Fan only |

51.8 |

23.5 (55.8) |

$8.18 |

With use of thermostat |

22.8 |

10.3 (22.7) |

$3.60 |

- Calculated at 16 hours of drive time per day, 240 operating days per year, a power–CO2 emissions conversion coefficient of 0.453 kg–CO2/kWh (1.00 lb–CO2/kWh), and electric utility rate of 0.16 USD/kWh

Compatible Products

New Equipment Design Considerations

The Electrification of Air Cylinders

Oriental Motor has a product line of linear & rotary actuators that are compatible with the electrification of air cylinders. The αSTEP AZ Series with on-board battery-less absolute sensor can perform high-accuracy positioning and limit the torque generated by a motor to the desired value (push-motion operation, etc.), rather than just performing speed control. Linear & rotary actuators that use them as the drive source are available.

Product Line that Supports Various Mechanisms and Operations

|

Compact Electric Linear Cylinders Automatically controls the operation of the fan in accordance with temperature fluctuations inside the equipment. This helps improve the equipment's "environmental" performance relative to energy savings, noise reduction, etc. |

|

This series offers the delicate grip of human fingertips. The drive motor is an αSTEP AZ Series stepper motor equipped with an Absolute Sensor. |

|

Electric Linear Cylinders The motor component incorporates a high-efficiency, energy-saving αSTEP AZ Series electric cylinder. In addition to straight-type actuators, reversed motor types with shorter overall length that can save space are also available. |

|

Rack-and-pinion Systems L Series These linear & rotary actuators (linear motors) combine a rack-and-pinion mechanism and motor. Equipped with an AZ Series stepper motor with battery-free Absolute Sensor, they can transport heavy loads up to 100 kg in addition to offering high positioning accuracy. This contributes to more compact equipment and less production work. |

|

Hollow Rotary Actuators This is a line of integrated products that combines a hollow rotary table with an αSTEP. The actuator has an internal speed reduction mechanism, which makes high power driving possible. |

- The specifications of the particular model in each series are provided as reference.

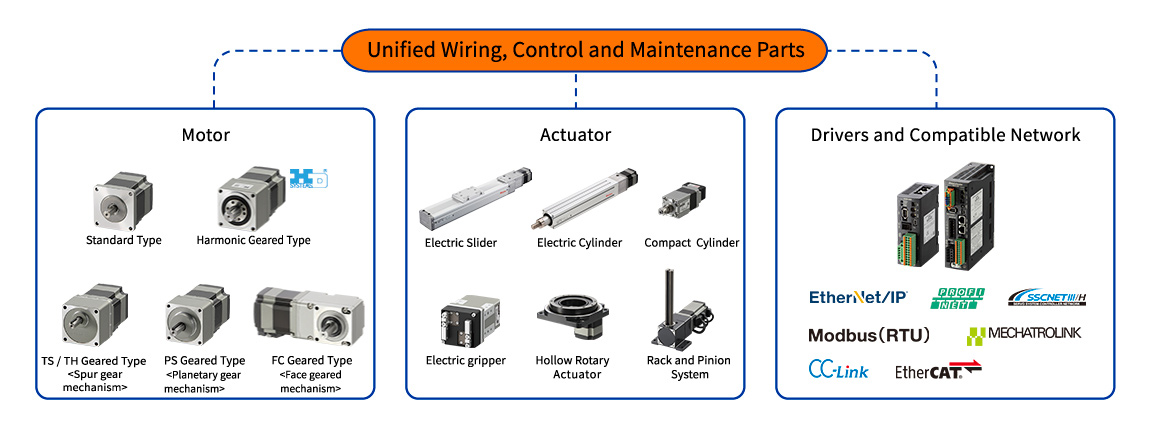

Various Operations Achieved with Unified Control

The αSTEP AZ Series offers not only standard type motors from a small size up, but also geared motors and motors containing linear & rotary actuators combined with mechanical components. Both AC input (100–240 VAC) and DC input (DC 24/48 VDC) drivers are available. There is also a full product line of FA network-compatible products. Because the motors, drivers, and cables are shared, wiring, control, and maintenance parts can be standardized by selecting the same series for the equipment, reducing the startup time and labor involved.

- EtherCAT® is a registered trademark for a patented technology licensed by Beckhoff Automation GmbH (Germany).

- EtherNet/IP™ is a trademark of ODVA.

- MECHATROLINK is a registered trademark of MECHATROLINK Members Association.

- SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation.

- CC-Link is a registered trademark of CC-Link Partner Association.

- Modbus (RTU) is a registered trademark of Schneider Automation Inc.

Improved Equipment Operating Ratio and Multi-functionality

Making use of monitoring and information functions in network-compatible products contributes to a higher equipment operating ratio. This leads to a reduction in wasted electricity caused by unexpected equipment stoppages, as well as decreased power consumption across the plant.

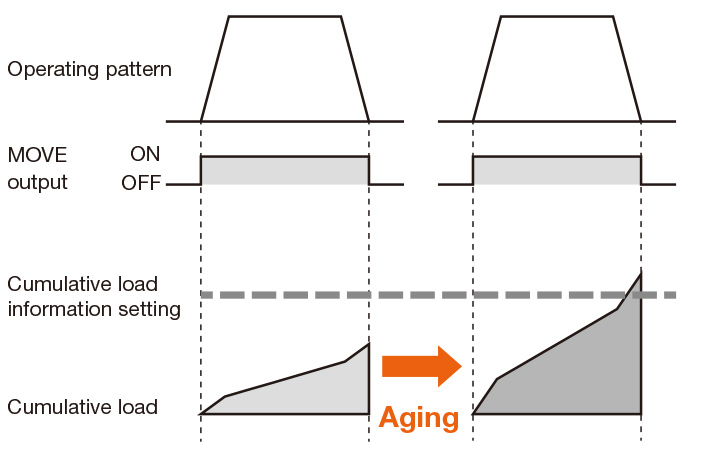

Example) Cumulative load monitoring |

Example) Using a monitor to conduct two operations simultaneously |

|---|---|

The AZ Series grasps a motor’s load factor across area via cumulative load monitoring, and detects it as a value. This is useful for determining long-term changes in a load due to age deterioration, etc. |

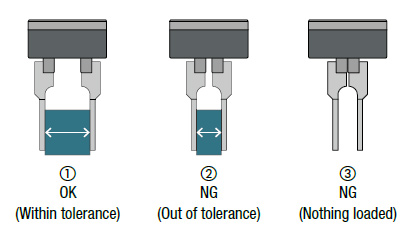

Air cylinders need sensors to determine the size of the load. The EH Series of Electric Gripper with on-board AZ Series uses the motor’s encoder information to determine dimensions and grip at the same time. |

|

|

More Compact and Lighter Weight Equipment

Oriental Motor has a wide range of products that can help achieve smaller and lighter equipment, robots, etc.

Having more compact and lighter weight equipment overall means less motor output for driving, resulting in lower power consumption.

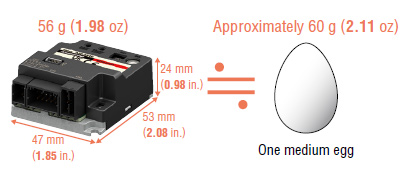

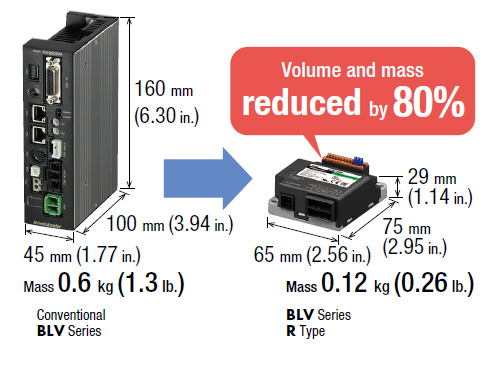

Achieving More Compact and Lightweight Equipment with the Latest Driver

| αSTEP AZ Series mini Driver |

BLV Series R Type |

|---|---|

|

The AZ Series not only performs speed control with high positioning accuracy, but can also control the motor’s generated torque to a desired value (push-motion operation, etc.). |

These DC input brushless motors offer speed control from 1 r/min. Both the motor and driver are significantly smaller and lighter, and can fit into a small space inside equipment. The mini driver can also monitor power consumption. |

|

|

Product Use Considerations

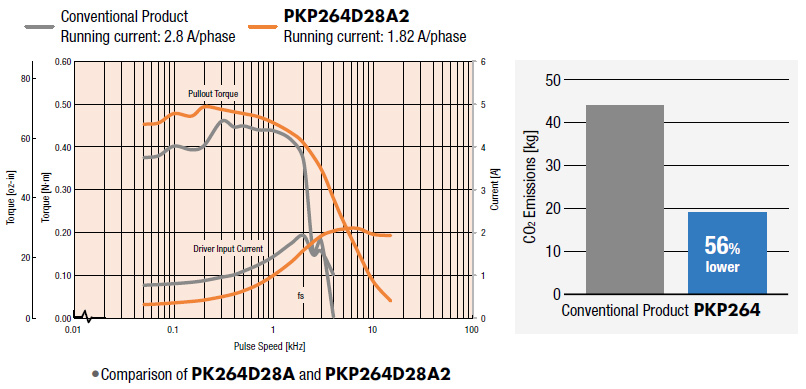

Reduced Power Consumption with a High-torque Stepper Motor

Effectively using a high-torque motor can reduce power consumption. After revising the magnetic design and structure design of the PKP Series of stepper motors, it produces much more torque than conventional products of the same size. In addition, torque can be increased in the high-speed range by using high current motors. There are also drivers that can maximize the performance of the PKP Series.

Stepper Motors PKP Series |

Bipolar Driver for 2-phase Stepper Motor |

The Effects of Using the PKP Series

Comparison of Speed–Torque Characteristics and CO2 Emissions

The high torque of the PKP Series can be utilized to achieve a running current with the same torque as a conventional product to reduce CO2 emissions.

|

|

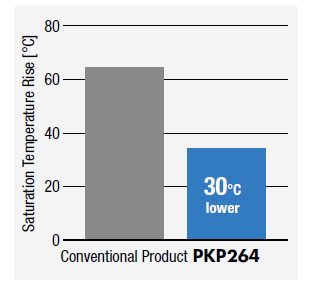

Comparison of Motor Temperature Rise

Temperature rise in the motor can be suppressed by lowering the running current in the PKP Series. This increases the life of the motor.

|

|

Compatible Products

|

High-Torque Stepper Motors This is a high torque and low vibration 2-phase stepper motor with a basic step angle of 1.8° (resolution of 200 steps per revolution). A wide variety of products is available for selecting a motor that meets the design specifications. (A separate dedicated driver is required to operate each motor.) |

|

Driver for Stepper Motors These are DC input drivers for 2-phase and 5-phase stepper motors. The microstep drive function for low-vibration drivers further reduces vibration. Three types of driver are available, depending on the installation direction and cable drawing direction. |

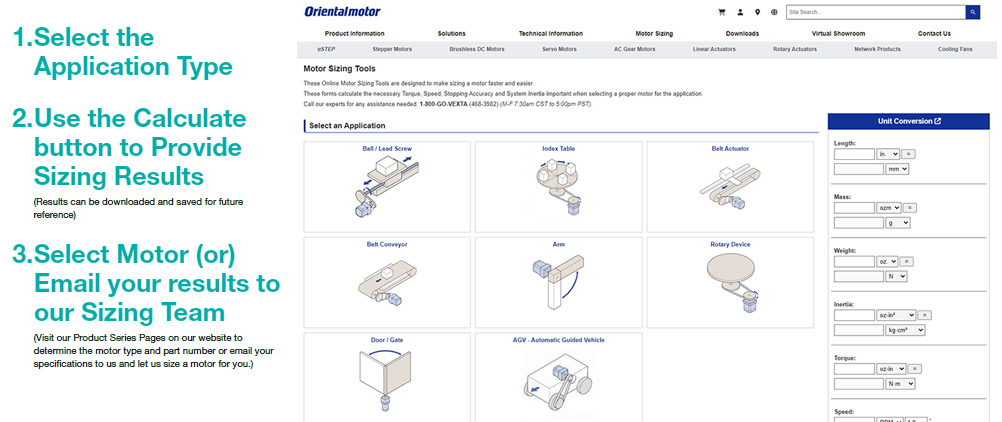

Choosing the Optimal Products

Using the Optimal Products with Our Selection Service

Using a motor that is over specification can consume more power than necessary. Oriental Motor provides various sizing and selection services that can cut down the time and labor needed to select the right motor.

Ask our Specialists

Our specialist staff can make the selection on behalf of a customer. Please submit a request through the website or by fax. |