BMU Series Brushless DC Motors (AC Input)

BMU Series Brushless DC Motors (BLDC Motors) (AC Input)

The BMU Series features a compact, high-power and high-efficiency brushless DC motor and is combined with an easy to use, easy to set speed controller. The entire motor structure features our latest brushless DC motor technology and has been innovated in pursuit of the optimal performance.

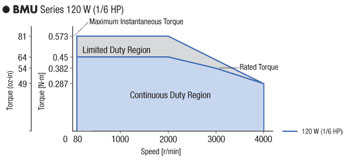

The BMU Series has a maximum speed of 4000 r/min. Speed ratio of 1:50 (80 to 4000 r/min) is achieved. Featuring 30 W (1/25 HP), 60 W (1/12 HP), 120 W (1/6 HP), 200 W (1/4 HP), 300 W (2/5 HP) and 400 W (1/2 HP) output power models.

- Speed Control Range: 80 ~ 4000 r/min

- Easy Wiring, Easy Set Up and Simple to Use Controls

- Parallel Shaft, Right-Angle Hollow Shaft Gear, Hollow Shaft Flat Gear or Round Shaft (no Gear)

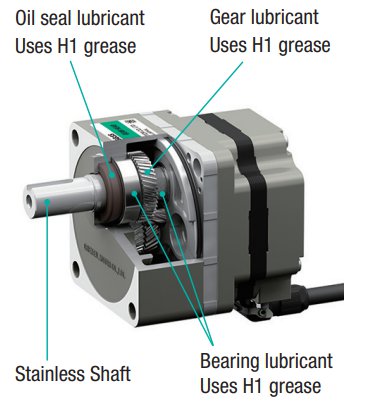

- H1 Food-Grade Grease-Compatible gear motors available.

- Imperial or Metric Shafts Available

- IP65, IP66 and IP67 Types Available

Brushless DC Motor & Gear Motor Lineup

Output Power |

Gear Options |

Power Supply |

Rated Torque |

Speed Range |

|

Parallel Shaft or |

Single-Phase 100-120 VAC |

3.9 ~ 53 lb-in |

0.45 ~ 6 N·m |

80 ~ 4000 r/min Min: 0.4 [200:1] |

|

Hollow Shaft Flat Gear |

3.5 ~ 150 lb-in |

0.4 ~ 17 N·m |

|||

Round Shaft (no Gear) |

13.6 oz-in |

0.096 N·m |

|||

Parallel Shaft or |

Single-Phase 100-120 VAC |

7.9 ~ 141 lb-in |

0.9 ~ 16 N·m |

80 ~ 4000 r/min Min: 0.4 [200:1] |

|

Right-Angle Hollow Shaft (Stainless Steel)* |

10.6 ~ 182 lb-in |

1.2 ~ 20.6 N·m |

|||

Hollow Shaft Flat Gear |

7.5 ~ 300 lb-in |

0.85 ~ 34 N·m |

|||

Round Shaft (no Gear) |

27 oz-in |

0.191 N·m |

|||

Parallel Shaft or |

Single-Phase 100-120 VAC |

17.7 ~ 260 lb-in |

2 ~ 30 N·m |

80 ~ 4000 r/min Min: 0.4 [200:1] |

|

Right-Angle Hollow Shaft (Stainless Steel)* |

28.3 ~ 477 lb-in |

3.2 ~ 53.9 N·m |

|||

Hollow Shaft Flat Gear |

16 ~ 680 lb-in |

1.9 ~ 77 N·m |

|||

Round Shaft (no Gear) |

54 oz-in |

0.382 N·m |

|||

Parallel Shaft |

Single-Phase 100-120 VAC |

25 ~ 610 lb-in |

2.9 ~ 70 N·m |

80 ~ 4000 r/min Min: 0.07 [1200:1] |

|

Parallel Shaft (Foot Mount)* |

21.2 ~ 4584 lb-in |

2.4 ~ 518 N·m |

|||

Parallel Shaft (Stainless Steel Shaft)* |

1168 ~ 1752 lb-in |

132 ~ 198 N·m |

|||

Right-Angle Hollow Shaft (Stainless Steel)* |

18.59 ~ 732 lb-in |

2.1 ~ 82.8 N·m |

|||

Hollow Shaft Flat Gear |

47 ~ 470 lb-in |

5.4 ~ 54 N·m |

|||

Round Shaft (no Gear) |

90 oz-in |

0.637 N·m |

|||

Parallel Shaft |

Single/Three-Phase 200-240 VAC |

38 ~ 610 lb-in |

4.3 ~ 70 N·m |

80 ~ 4000 r/min Min: 0.07 [1200:1] |

|

Parallel Shaft (Foot Mount)* |

31 ~ 3400 lb-in |

3.6 ~ 388 N·m |

|||

Parallel Shaft (Stainless Steel Shaft)* |

1210 ~ 2600 lb-in |

137 ~ 297 N·m |

|||

Right-Angle Hollow Shaft (Stainless Steel)* |

29 ~ 1180 lb-in |

3.3 ~ 134 N·m |

|||

Hollow Shaft Flat Gear |

71 ~ 710 lb-in |

8.1 ~ 81 N·m |

|||

Round Shaft (no Gear) |

135 oz-in |

0.955 N·m |

|||

Parallel Shaft |

Three-Phase 200-240 VAC |

50.4 ~ 483.2 lb-in |

5.7 ~ 54.6 N·m |

80 ~ 4000 r/min Min: 0.19 [600:1] |

|

Parallel Shaft (Foot Mount)* |

47.79 ~ 5159 lb-in |

5.4 ~ 583 N·m |

|||

Parallel Shaft (Stainless Steel Shaft)* |

955.8 ~ 3814 lb-in |

108 ~ 431 N·m |

|||

Right-Angle Hollow Shaft (Stainless Steel)* |

42.48 ~ 1575 lb-in |

4.8 ~ 178 N·m |

|||

Hollow Shaft Flat Gear |

46 ~ 940 lb-in |

5.3 ~ 107 N·m |

|||

Round Shaft (no Gear) |

180 oz-in |

1.27 N·m |

|||

*Maximum input speed for Gearhead limited to 3600 r/min.

**Parallel Shaft only.

Easy, Afforable Speed Control

High Performance Speed Control

The BMU series brushless DC motor speed control system offers a maximum speed of up to 4000 r/min (80 to 4000 r/min). This allows for a wider speed range, wider selection of gear ratios and torque ranges making the BMU Series an ideal alternative for servo, brushed motors or AC three-phase Inverter driven applications.

Affordable Price

The BMU series brushless DC motor speed control systems offer user-friendly features and expanded functions at an affordable price. Now offering even more value and performance, the BMU series BLDC motor, driver and gearhead come together as one part number; saving time when ordering and ensuring a complete solution, guaranteed.

No Maintenance, Longer Life

In a brushless DC motor, there are no brushes and thus no physical contact the could lead to frictional energy losses.

While brush DC motors use a brush and commutator to rotate and require regular maintenance, Brushless DC Motors (BLDC Motors) rotate by the ON/OFF operation of the drive circuit transistor, based on the signals detected by the hall effect IC (magnetic sensor).

Brushless DC Motors (BLDC Motors) are more expensive to design and manufacture, however, they are typically more efficient than brushed DC motors.

This leads to:

- No maintenance, longer life

- More power

- Longer runtime

Easy Speed Control

Using the dial and digital speed indicator, controlling the BMU series brushless DC motor speed is simple and user-friendly.

Turn the dial and set the desired speed. Push to set (store) the desired speed. After the speed has been set, it can easily be changed by operating the dial. The dial can be locked to prevent changes in speed with the dial lock operation.

Easy Wiring, Easy Set Up

Get started quickly and easily. Connecting the motor is simple using the included cables with connectors. The power and I/O connectors feature a screwless connector, eliminating the need for soldering or crimp tools. Start the motor with one switch; the motor starts when the switch is set to "RUN" and decelerates to a stop if set to "STAND-BY". It's also simple to change the rotation direction of the motor using the rotation direction switch on the front of the driver.

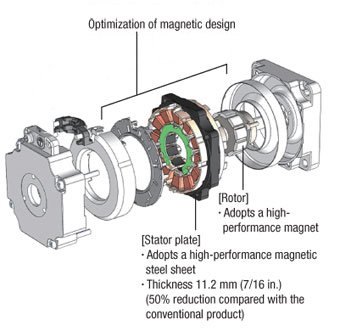

A New Motor Design: Compact, High-Power and High-Efficiency

An optimal magnetic design and high-performance material enable the new brushless DC motor stator plate to have a thickness of just 7/16 in. (11.2 mm). This slim design achieves a highly efficient power unit that outputs 120 W (1/6 HP). Compared with the conventional brushless DC motor of the same output power, the stator plate thickness is only half of the conventional one.

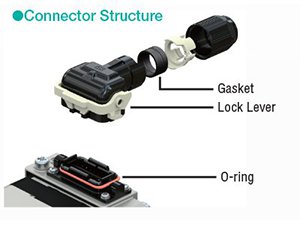

Degree of Protection IP66

The connector is newly developed for small motors and enables a direct connection between the motor and driver. Connecting is easy due to the lock lever that does not require screws. Also, the motor structure has achieved an IP66* degree of protection for its improved watertight and dust-resistant performance. The internal gasket and O-ring improve the watertight performance.

*The degree of protection and output shaft material vary depending on the types of gearheads combined. See the product lineup for details.

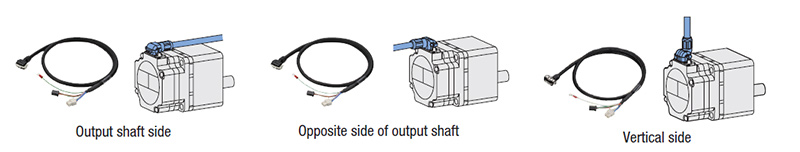

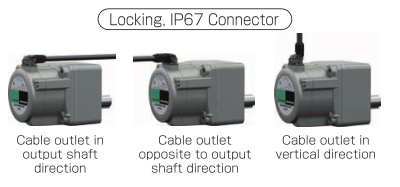

Selectable Cable Outlet Direction

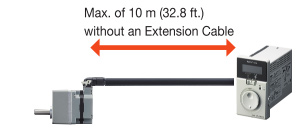

Three types of the connection cables are available, depending on which direction the cable will be drawn. Since a single connection cable can connect directly between the driver and motor at a distance of up to 20 m (65.6 ft.), no extension cable is required.

Easy to Use Controller

(Typical functions that can be set while the front panel is opened)

- Motor Start/Stop*

- Adjusting the operating speed*

- Setting the operating speed*

- Selecting the rotation direction*

- Changing the indication

- Indicating the operating speed when the speed reduction/speed increasing

ratio is set - Setting the acceleration/deceleration time

- Dial operation lock

- Speed setting for the 4-speed operation

- Speed limits setting

- Validating the external operating signals

- External input/output signal allocation

- Setting the overload alarm detection time, except during axial lock

- Load holding function for output shaft

*Setting is possible even if the front panel is attached.

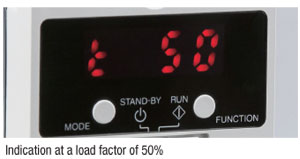

Load Factor can be shown

With the rated torque of the motor at 100%, the load factor can be expressed as a percentage (40-200%). The load condition during start-up, as well as the load condition due to the aging deterioration of the equipment can be confirmed.

Dial Operation Lock Function

This prevents the undesired changes in the speed and the changes or deletion of data with the operation of the dial. At the main screen for each operating mode, press the "MODE" key for 5 seconds or more. When "Lk" appears the lock function is activated.

Canceling the Lock Function

Return to the main screen and press the "MODE" key for 5 seconds or more. When "UnLK" is indication the lock function has been cancelled.

Long-Life, Parallel Shaft Gearhead (IP66)

- 30 W (1/25 HP)

- 60 W (1/12 HP)

- 120 W (1/6 HP)

- 200 W (1/4 HP)

- 300 W (2/5 HP)

- 400 W (1/2 HP)

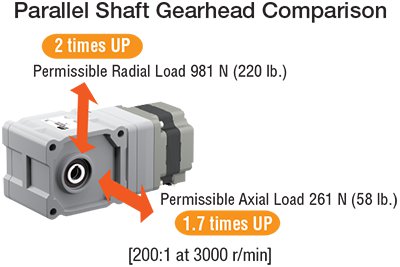

High-Strength Gearhead

High strength is achieved through improving the strength of gears through heat treatment and through larger bearing diameters. The high permissible torque is 2 ~ 3 times that of a gearhead for an AC motor with the same frame size, and this contributes to reducing the size of equipment.

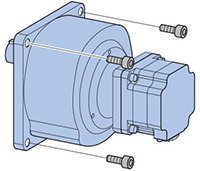

New Gearhead (combination type)

With the gearhead's boss and machined mounting surface, the installation accuracy has been greatly improved. The new gearhead also has lower audible noise as compared to our previous type and comes pre-assembled (motor and gear) as a combination type.

Long Life

A long life gearhead that uses a special bearing and grease for high speed rotation.

A rated life of 10000 hours is achieved.

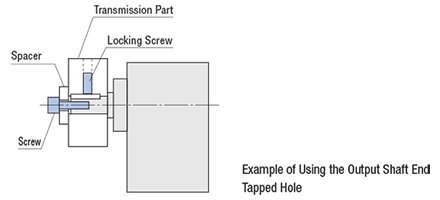

Tapped Hole at the End of the Output Shaft (GFV Gear 80 mm (3.15 in.) min.)

A tapped hole has been machined at the tip of the output shaft. This can be used as an aid for preventing transmission parts from coming off.

Standardized Use of Stainless Steel Shaft

These brushless DC IP66 motors include a shaft made of SUS303 type steel, which provides excellent rust prevention and corrosion resistance. Stainless steel is also used in the parallel keys and installation screws.

H1 Food-Grade Grease-Compatible (IP66)

- 30 W (1/19 HP)

- 60 W (1/12 HP)

- 100 W (1/8 HP)

H1 Food-Grade Grease-Compatible Gearhead

The gearhead uses the NSF registered H1 food-grade lubricant (grease).

What is H1 Food-Grade Grease?

It is a grease registered by the NSF as part of a category where the "lubricants used in food-processing environments where there is the possibility of incidental food contact."

What is NSF International?

NSF is an American-based international, third-party certification body which provides global services such as development of standard, product certification, auditing, training and risk management for the public health and environmental sectors.

Watertight, Dust-Resistant Parallel Shaft (IP67)

- 200 W (1/4 HP)

- 300 W (2/5 HP)

- 400 W (1/2 HP)

Watertight, dust-resistant brushless motors that withstand wet and dusty environments and can be washed with water.

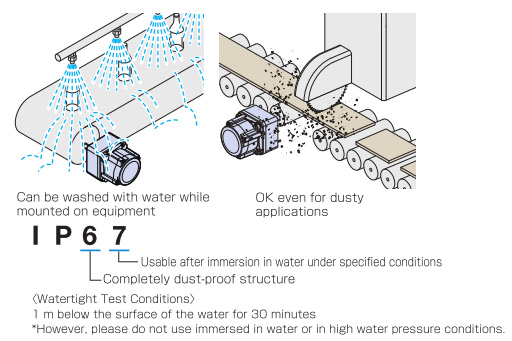

Degree of Protection IP67

Can be used in dusty and wet environments. Can be washed with water.

Designed to be mounted on equipment as-is with no protective cover.

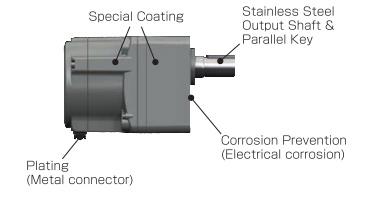

Rust Resistant

The motor is covered with a special rust-resistant coating, with an output shaft and screws made of stainless steel. The installation surface is also painted, so it will be rust-resistant even when installed in stainless steel equipment.

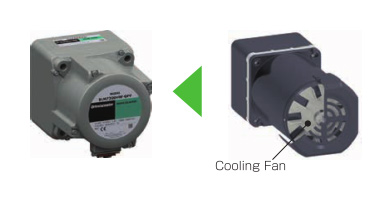

Suited for Clean Environments

The motor is highly efficient, so it has no cooling fan.

Easy Equipment Design

3 cable outlet directions can be selected, increasing the freedom of equipment design. Enables relay-free, direct connection between the motor and driver.

Parallel Shaft (Foot Mount Type) - JB Gear (IP44)

- 200 W (1/4 HP)

- 300 W (2/5 HP)

- 400 W (1/2 HP)

Foot Mount Gearhead JB Gear

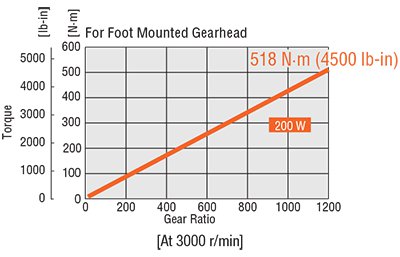

The gear ratio is 1/1200 with maximum allowable torque of 518 N•m. Torque is not saturated with the new gearhead, therefore, maximum output torque is available at each gear ratio.

No Mounting Bracket Needed

Configured so it can be quickly installed on equipment.

High Rigidity / Internal Structure

Well designed shaft axis, integrated construction with installation surface.

High Permissible Torque

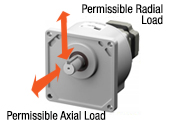

High permissible radial and axial load strength enables powerful, high-spec operations.

Superior Mechanical Strength

High permissible radial and axial load strength enables powerful, high-spec operations.

IP66 Parallel Shat (Stainless Steel Shaft) Type - JV Gear

- 200 W (1/4 HP)

- 300 W (2/5 HP)

- 400 W (1/2 HP)

Superior Mechanical Strength

High permissible radial and axial load strength enables powerful, high-spec operations.

- Stainless Steel Shaft

Can Be Installed on the Flange Surface

IP66 Right-Angle Hollow Shaft (Stainless Steel) - JH Gear

- 60 W (1/12 HP)

- 120 W (1/6 HP)

- 200 W (1/4 HP)

- 300 W (2/5 HP)

- 400 W (1/2 HP)

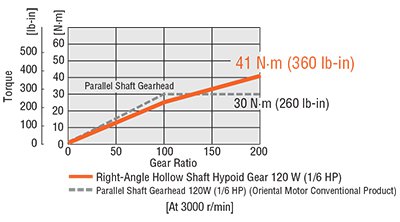

High Allowable Torque

Torque is not saturated with the new right-angle hollow shaft Hypoid JH gear, therefore, maximum output torque is available at each gear ratio.

- Stainless Steel Shaft

Superior Mechanical Strength

High permissible radial and axial load strength enables powerful, high-spec operations.

Pre-Assembled Motor & Gearhead

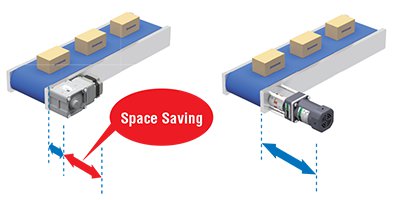

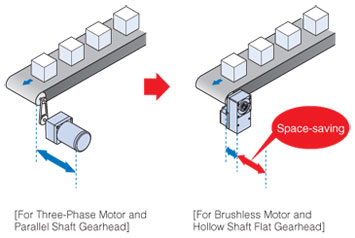

Space Saving

Space reduction is achieved when mounted along side the conveyor belt. Because the output shaft of the gear is vertically in the middle of the installation surface, it is possible to change the installation direction horizontally, tailored to equipment position of installation.

Low Cost

Component cost saving is achieved through reduction of fastening parts, assembly steps reduced through mechanism simplification. Maintenance cost is also reduced or eliminated as a result.

Flexible Installation

The gearhead can be removed and the assembly position can be changed in 90˚ increments. The connector positions can also be changed to suit the equipment.

Hollow Shaft Flat Gearhead - FR Gear (IP65)

- 30 W (1/25 HP)

- 60 W (1/12 HP)

- 120 W (1/6 HP)

- 200 W (1/4 HP)

- 300 W (2/5 HP)

- 400 W (1/2 HP)

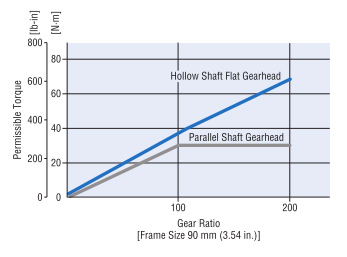

Permissible Torque without Saturation

The hollow shaft flat gearhead enables permissible torque without saturation even at high gear ratios. The motor torque can be fully utilized.

Low Cost

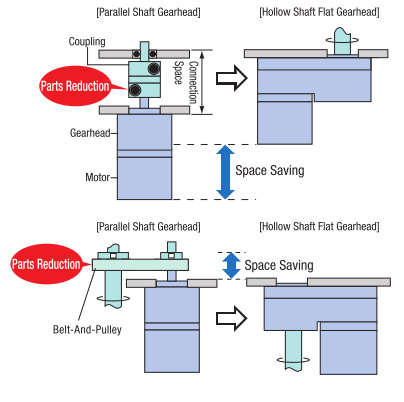

By eliminating parts such as a coupling or belt-and-pulley, the parts cost and labor will also decrease.

Space Saving is Achieved with a Hollow Shaft Flat Gearhead

The output shaft can be coupled directly to your drive shaft without using a coupling. The flexible installation modes, such as installation on either the front or rear face or by using the center shaft, allows you to reduce the size and installation space of your equipment. Since no shaft-coupling parts are needed, the parts cost and assembly man-hours will also decrease.

Connection / Extension Cables (required)

These cables are required to connect the motor and driver. Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Power Supply Cables

Power Supply cable for the BMU Series.

Front Panel Cover for Driver

Provides IP64 protection and prevents changes to the driver.

Motor Size |

Item |

30 W (1/25 HP) |

|

200 W (1/4 HP) |

IP66 Motor Cover

This cover protects the motor. They are compatible with the degree of protection IP66 specification and can be used in wet and dusty environments.

Output |

Motor |

Direction of Cable Outlet |

30 W (1/25 HP) |

Parallel Shaft Gearhead - GFV Gear |

|

Round Shaft (no Gear) |

|

Rotary Encoders

Small, thin, and lightweight stand-alone rotary encoders with an outer diameter of ϕ30 mm can be installed in tight spaces.

Flexible Couplings

These products are clamp type couplings used to connect a motor or gearhead shaft to the shaft of the equipment.

Mounting Bracket

This is an aluminum die cast mounting bracket for geared motors.

Long, horizontal holes make it easy to make fine adjustments during installation.

Flange Drive Adapter

Permissible load has been increased by mounting with a parallel shaft gearhead. Direct mounting of the rotation mechanism to wheels or rotary tables has been simplified, which helps reduce design time.

*For use with 120W Parallel Shaft Gear Motors (Metric Shaft)

Driver Mounting Brackets

Driver mounting brackets.

- Panel Mount or DIN Rail

Motor Size |

Panel |

DIN Rail |

30 W (1/25 HP) |

||

200 W (1/4 HP) |

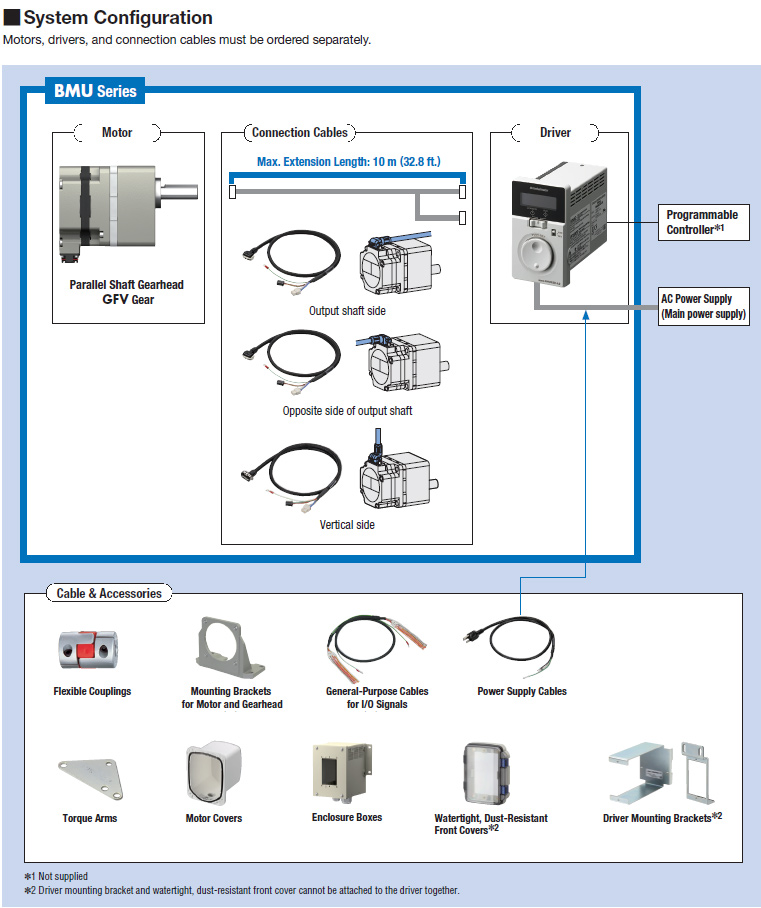

System Configuration

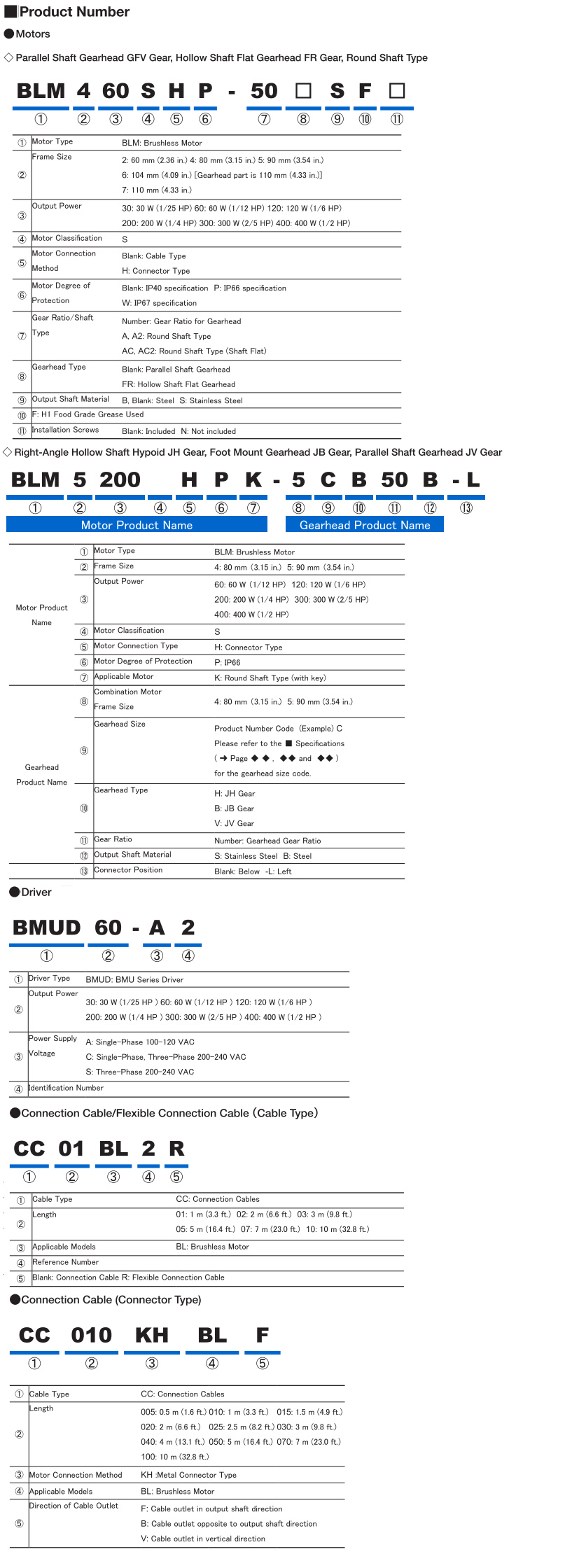

Part Number Code

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.