Rotary Actuators

αSTEP Rotary Actuators

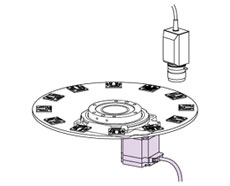

The DGII Series is a line of integrated product that combines a hollow rotary table with an αSTEP closed loop stepper motor. The rotary actuator has an internal speed reduction mechanism, which makes high power driving possible.

The rotary actuators achieve both high power and high rigidity by adopting the cross-roller bearing on the hollow output table.

Learn more about our αSTEP family of products

Rotary actuators provide a simplified design to reduce time and cost designing and installing the necessary parts.

- 60 mm (2.36 in.) up to 200 mm (7.87 inch.) Frame Sizes

- Vertical or Horizontal Motor Mount Types

- Electromagnetic Brake options

- AC or DC Input Drivers

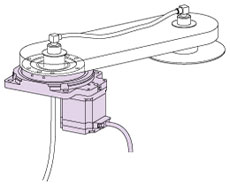

Hollow Rotary Actuators

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an αSTEP closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

- Integrated actuator and stepper motor makes design easier

- Vertical or Horizontal Motor Mount Types

- Large-diameter hollow output table

- AC or DC Input

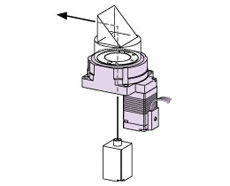

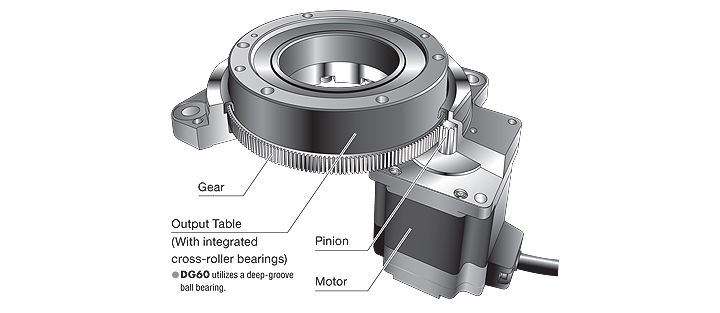

Hollow Rotary Gearhead

This is a standalone hollow rotary gearhead from the DGII Series. The gearhead structure remains the same as the DGII Series and is designed for use with servo motors from various manufacturers, connected via the actuator's coupling. It is ideal for large-inertia drive applications.

- Large-diameter hollow output table

- To use with servo motors from various manufacturers

Drivers

Stepper motor drivers convert pulse signals from the controller into motor motion to achieve precise positioning.

- AC or DC Input

- Driver Types:

- Pulse Input

- Pulse Input with RS-485 Communications

- Built-in Controller

- EtherNet/IP™ and EtherCAT Compatible versions

EtherNet/IP™ is a trademark of ODVA

Network Gateways

Network Gateways for use with motion control systems.

- Network Converters/Gateways (RS-485 Communication)

- EtherCat

- CC-Link

- MECHATROLINK

Rotary Actuators

Hollow Rotary Actuators

The gear-reduction mechanism employs precision gears along with a proprietary adjustment mechanism that eliminates backlash. The repetitive positioning accuracy from a single direction is ±15 sec., while lost motion in a positioning operation from two directions is 2 arc minutes. These characteristics make the DGII series the ideal choice for applications in which accurate positioning is a must.

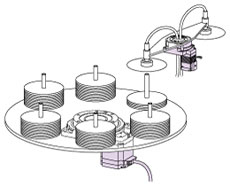

Application Examples

Applications subject to changing load inertia |

Applications where a moment load is applied |

Optical applications using the hollow hole |

|

|

|

High accuracy positioning applications |

High accuracy positioning applications using the hollow hole |

Air absorption applications using the hollow hole |

|

|

|

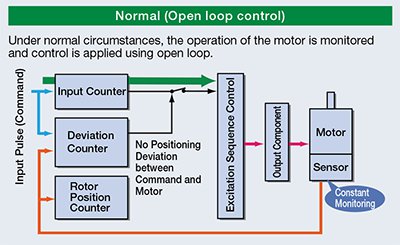

Hybrid Control System

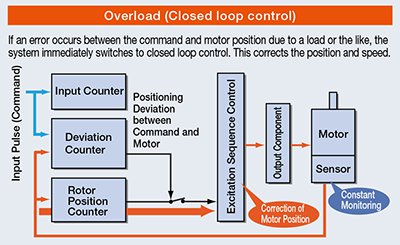

αSTEP products are stepper motor based hybrid motors with a unique hybrid control system combining the benefits of "open loop control" and "closed loop control".

The position of the motor is always monitored, and then the driver automatically switches between 2 types of control depending on the situation.

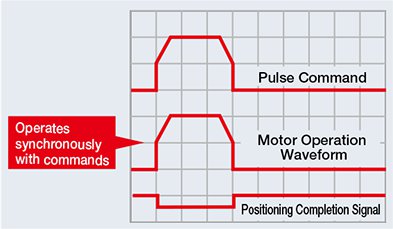

Normally Operates in Open Loop Control for the Same Ease of Use as a Stepper Motor

High Response

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

Holding the Stop Position without Hunting

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

Tuning-Free

Because it is normally operated with open loop control, positioning is still possible without gain adjustment even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Switches to Closed Loop Control during Overload for More Reliable Operation like a Servo Motor

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

It operates synchronously with commands using open loop control during normal conditions. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.