AZ Series EtherNet/IP™ Compatible Drivers (AC Input)

αSTEP Hybrid Step-Servo

AZ Series EtherNet/IP™ Compatible Drivers

AZ Series Stored Data drivers now offer EtherNet/IP™ communications for a battery-free, absolute mechanical sensor motor and driver solution.

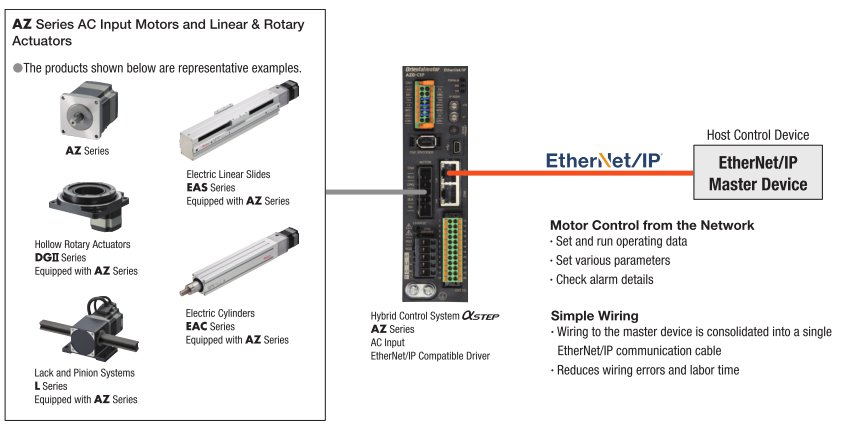

For use with all Oriental Motor AZ Series motors and linear & rotary actuators equipped with the AZ Series.

- Built-in Protective Functions

- Monitoring Functions

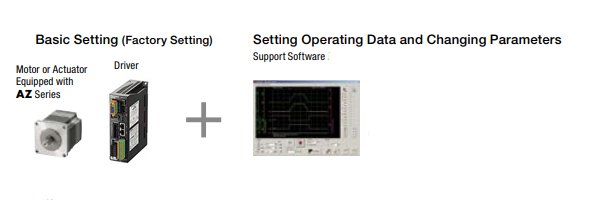

- Support Software for Paramater Setting (free download)

- 24/48 VDC, Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with AZ Series Motors & Products

![]()

EtherNet/IP™ is a trademark of ODVA.

Product Lineup

Item |

Network |

Power Supply |

Control Power Supply |

EtherNet/IP™ |

EtherNet/IP™ |

24 VDC |

|

mini Driver with |

24/48 VDC | ||

EtherNet/IP™ |

|||

αSTEP Performance

What is the Output of αSTEP?

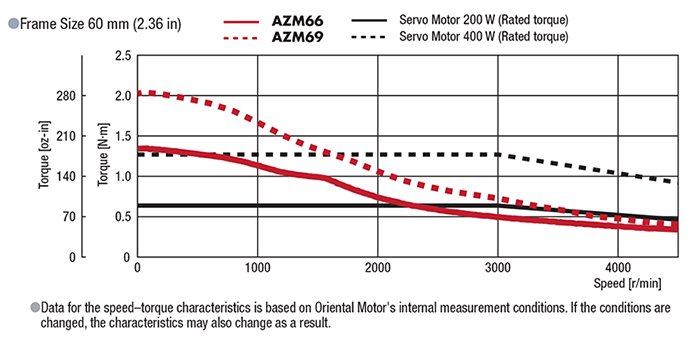

"Rated Output" is not listed because αSTEP has no "rated speed". Refer to the graph below to compare rate torque of the αSTEP to Watts of of servo motor's rated output torque.

What is the Stopping Accuracy of αSTEP?

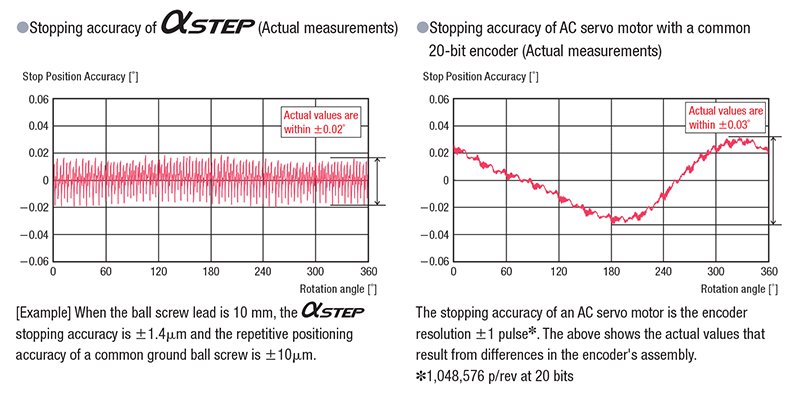

The stopping accuracy of a typical αSTEP is ±0.05° (under no load), which is equivalent to that of servo motors. The graphs below show the actual measured stopping accuracies when an αSTEP and an AC servo motor were rotated once.

Advanced Technology at Affordable Prices

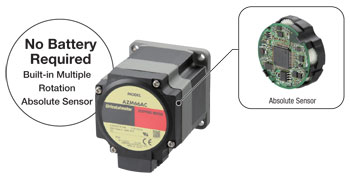

Oriental Motor has developed and patented a compact, low-cost, battery-free mechanical type absolute sensor. The αSTEP AZ Series is available at affordable prices and can contribute to improved productivity and cost reductions.

Mechanical-Type Encoder (No Battery Required)

A mechanical sensor composed of multiple gears is employed. Positioning information is detected by recognizing the angle of the individual gears. As a result, it does not require a battery.

Multiple-Rotation Absolute System*

Absolute position detection is possible with ±900 rotations (1800 rotations) of the motor shaft from the home position.

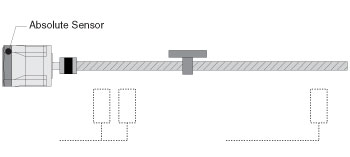

No External Sensors Required

Positional information is managed mechanically. External sensors such as home sensor and the limit sensor are not needed.

Reduced Cost

Sensor costs and wiring costs can be reduced, allowing for lower system costs.

Simple Wiring

Wiring is simplified and the degree of freedom for equipment design is increased.

Not Affected by Sensor Malfunctions

There is no concern about sensor malfunctions (when operating in environments filled with oil mist or filled with metal pieces due to metal processing), sensor failures or sensor wire disconnections.

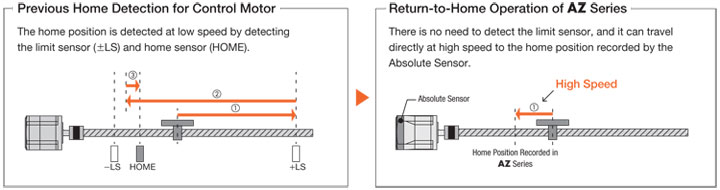

Improved Return-to-Home Accuracy

Home position accuracy is increase because the return-to-home operation is performed regardless of any variations in home sensor sensitivity.

Shortened Reset Time - High Speed Return-to-Home

Because return-to-home is possible without an external sensor, return-to-home can be performed at high speed without taking the sensor sensitivity into account, allowing for a shortened machine cycle.

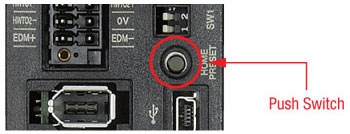

Home Setting Method

The home position can be easily set by pressing a switch on the drivers surface, which is saved by the Mechanical Absolute Encoder. In addition, home setting is possible with the MEXE02 data setting software or external input signal.

Home position is easy to adjust by moving the motor to a desired position manually.

No Battery Required

No battery is required thanks to a mechanical-type sensor. Because positioning information is managed mechanically by the Mechanical Absolute Encoder, the positioning information can be preserved, even if the power turns off, or the cable between the motor and the driver is disconnected.

Reduced Maintenance

Because there is no battery that needs replacement, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control box.

Safe for Overseas Shipping

Normal batteries will self-discharge, so care must be taken when the equipment requires a long shipping time, such as when being sent overseas. The Mechanical Absolute Encoder does not require a battery, so there is no limit to how long the positioning information is maintained. In addition, there is no need to worry about various safety regulations, which must be taken into consideration when shipping a battery overseas.

Position Holding Even when the Cable between the Motor and Driver is Detached

Positioning information is stored within the Mechanical Absolute Encoder.

*Because the positioning information is stored in the Mechanical Absolute Encoder, the home position must be reset if the motor is replaced.

More Control over the Network

EtherNet/IP™ Compatible Driver

With the EtherNet/IP driver, the operating data can sent from the host system or can be set in the driver and selected and executed from a host system. Host system connection and control are performed with I/O Stored Data or EtherNet/IP communications.

AZ Series EtherNet/IP™ Drivers

Easily control the AZ Series by directly connecting to the EtherNet/IP master device using a single EtherNet/IP communications cable. This allows for quick and simple wiring.

Support Software, EDS File & Add-On Instructions

An EDS file has been prepared to allow EtherNet/IP compatible products to be used more easily.

Add-On Instructions (AOI) for AZ Series EtherNet/IP drivers, v1.0 Use the AOI to save programming time or make it easier to read or write your data parameters in the AZ Series drivers.

- Move Command

- Operation Position / Speed

- Current Settings or Accel/Decel Settings

- Monitoring

- Direct Data Operation (changing data on the fly)

AZ Series Products

Eliminate Extra Sensors with a Battery-Free Absolute System

The αSTEP AZ Series Mechanical Absolute Encoder is available as a leading closed loop, battery free absolute motion solution sold as a Stepper Motor + Driver or Linear Actuator + Driver allowing for absolute, battery free, advanced performance across a wide range of applications.

Functional Safety - STO (Safe Torque Off) Function (AC Input Drivers)

SIL3, PL-e Functional Safety* Certification

*Incorporates the STO (Safe Torque Off) function

Applicable Standard |

Safety Level |

IEC 61800-5-2, EN 61800-5-2 |

Functional Safety |

IEC 61508-1, EN 61508-1 |

|

IEC 61508-2, EN 61508-2 |

|

IEC 62061, EN 62061 |

|

ISO 13849-1:2015, EN ISO 13849-1:2015 |

|

IEC 61800-5-1, EN 61800-5-1 |

Electrical Safety |

IEC 61000-6-7, EN 61000-6-7 |

EMC |

Applicable Products

Power Supply Input |

Type |

AC Input |

Built-in Controller |

Pulse Input with RS-485 Communications |

|

Pulse Input |

|

| |

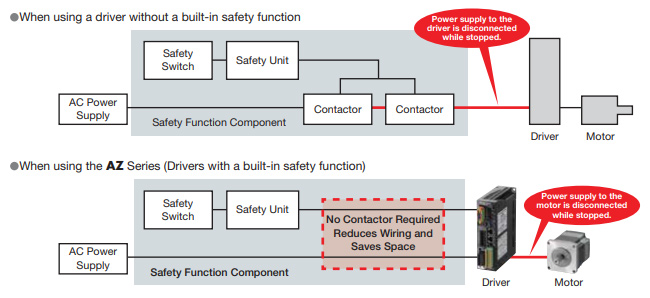

Drivers with Built-in Safety Functions Simplify Components

A driver with built-in safety function can prevent unintended operation, which eliminates the need for contractors.

This allows for reduced equipment wiring and saved space.

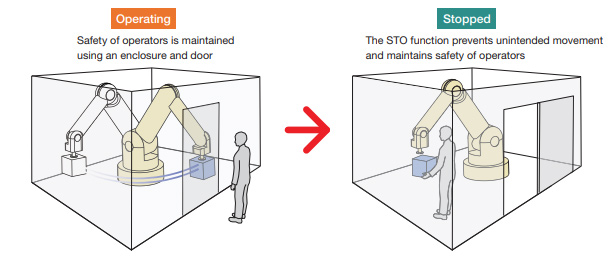

The STO Function Prevents Unintended Start of the Motor While it is Stopped

Certified products have an STO (Safe Torque Off) function, which disconnects the supply of power to the motors.*

By disconnecting the power supply to the motor, the risk posed by dangerous movement of the equipment's moving parts is reduced.

*Do not use during operation.

AZ Series Closed Loop Stepper Motors

The AZ Series offers high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires AZ Series Driver.

- Battery-Free, Mechanical Absolute Encoder

- Closed Loop Performance, No Hunting or Gain Tuning

- Wide Range of Gear Types for Inertia Matching & Higher Torque

- Electromagnetic Brake Type Available

DIN Rail Mounting Plate

Use to mount the driver on DIN rail.

Power Supply Cables

Power Supply cable for the AZ Series.

EtherNet/IP™ Support Software

Support Software and EDS file for EtherNet/IP.

Driver Cables (Built-in Controller Type)

It is a general-purpose multi-core cable convenient for connection between the driver and host controller.

Item |

Length |

3.3 ft. (1 m) |

|

6.6 ft. (2 m) |

24 VDC Control Power Cable

24 VDC power supply cable for driver

Item |

Length |

1.67 ft. (0.5 m) |

|

3.3 ft. (1 m) |

|

4.9 ft. (1.5 m) |

|

6.6 ft. (2 m) |

|

8.2 ft. (2.5 m) |

Regeneration Unit

During vertical driver (gravitational operation) or suddent start/stop in high inertia, an external force causes the motor to rotate and funciton as a power generator. When the regenerative power exceeds the driver's regenerative power absorption capacity, it may cause damage to the motor. In such a case, the regeneration unit is connected to the driver to convert regenerative energy into thermal energy for dissipation.

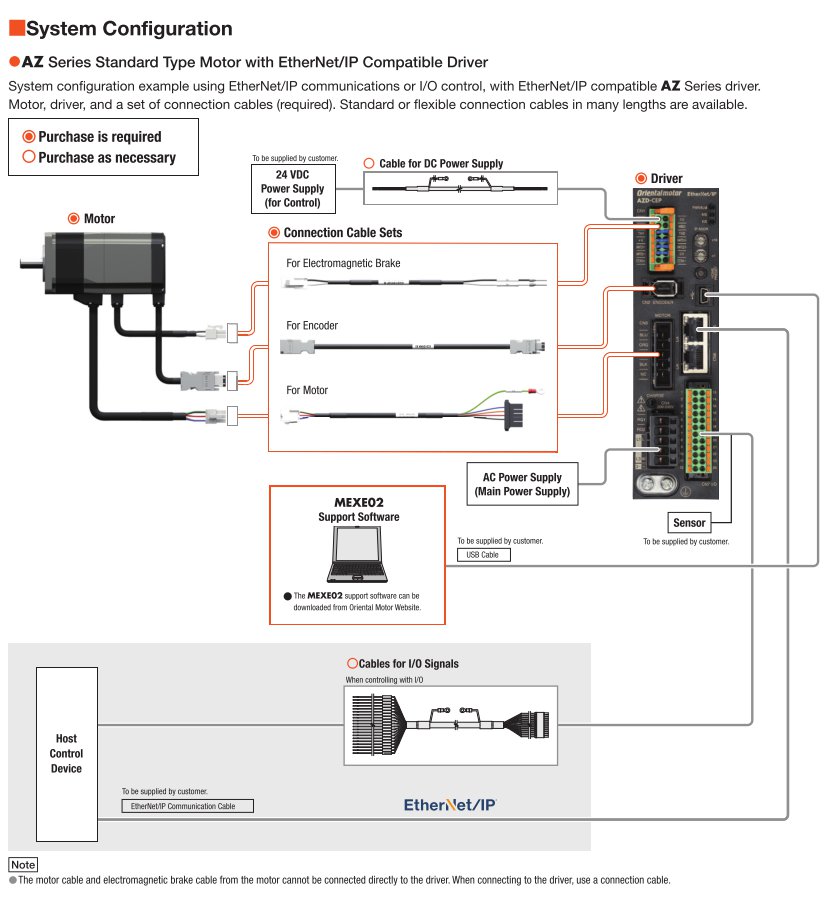

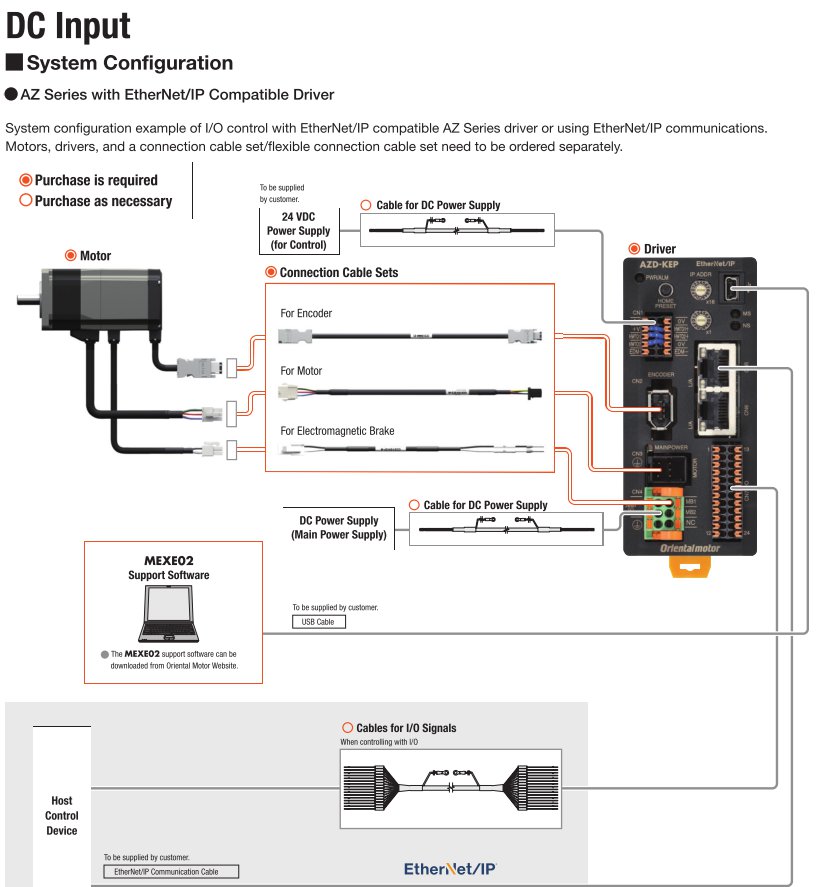

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.