AZ Series Closed Loop, Absolute Stepper Motors

AZ Series Stepper Motors with Mechanical Absolute Encoder

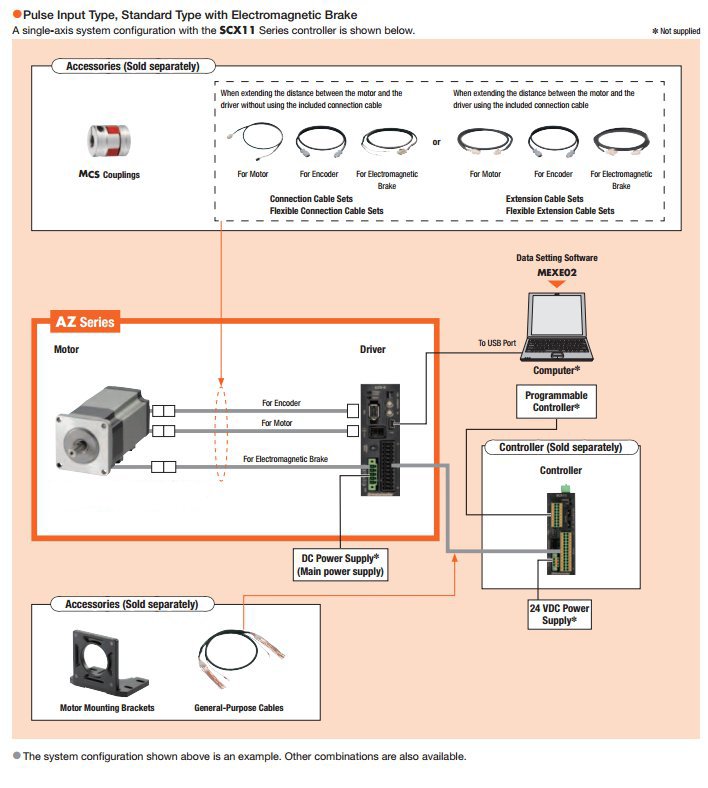

The αSTEP AZ Series stepper motors offer high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires αSTEP AZ Series Stepper Motor Driver.

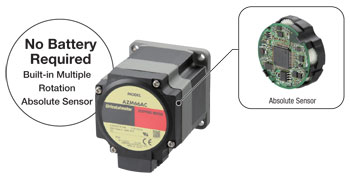

- Battery-Free, Mechanical Absolute Encoder

- Closed Loop Performance, No Hunting or Gain Tuning

- AC or DC Input Types

- Parallel Shaft and Right Angle Geared Types for Higher Torque, Space Savings

- Electromagnetic Brake Type and Connector Types Available

- αSTEP AZ Series Stepper Motor Driver Required*

Mechanical Absolute Encoder

Stepper Motor Lineup

Driver Power Input |

Frame Size |

Motor Types |

Available Options |

Max. Holding Torque |

|

AC Input |

Standard Type |

Electromagnetic Brake |

42 ~ 109 oz-in |

0.3 ~ 0.77 N·m |

|

Geared Type |

92 ~ 2407 oz-in |

0.65 ~ 17 N·m |

|||

Standard Type |

Electromagnetic Brake |

142 ~ 280 oz-in |

1 ~ 2 N·m |

||

Geared Type |

254 ~ 5664 oz-in |

1.8 ~ 40 N·m |

|||

|

AC Input |

Standard Type |

Electromagnetic Brake |

280 ~ 560 oz-in | 2 ~ 4 N·m | |

Geared Type |

53 ~ 974 lb-in | 6 ~ 110 N·m | |||

DC Input |

|

Standard Type | - |

2.8 ~ 5.1 oz-in | 0.02 ~ 0.036 N·m |

| Standard Type | - | 13.4 ~ 26 oz-in | 0.1 ~ 0.19 N·m | ||

| Geared Type | - | 42 ~ 340 oz-in | 0.3 ~ 2.4 N·m | ||

| Geared Type | - | 42 ~ 156 oz-in | 0.3 ~ 1.1 N·m | ||

|

|

Standard Type |

Electromagnetic Brake Connector Type |

42 ~ 102 oz-in |

0.3 ~ 0.72 N·m |

|

Geared Type |

92 ~ 2407 oz-in |

0.65 ~ 17 N·m |

|||

Standard Type |

Electromagnetic Brake |

142 ~ 280 oz-in |

1 ~ 2 N·m |

||

Geared Type |

254 ~ 5664 oz-in |

1.8 ~ 40 N·m |

|||

* Geared Stepper Motor frame size.

Mechanical Type Absolute Encoder

Advanced Technology at Affordable Prices

Oriental Motor has developed and patented a compact, low-cost, battery-free mechanical type absolute sensor. The αSTEP AZ Series is available at affordable prices and can contribute to improved productivity and cost reductions.

Mechanical-Type Encoder (No Battery Required)

A mechanical sensor composed of multiple gears is employed. Positioning information is detected by recognizing the angle of the individual gears. As a result, it does not require a battery.

Multiple-Rotation Absolute System*

Absolute position detection is possible with ±900 rotations (1800 rotations) of the motor shaft from the home position.

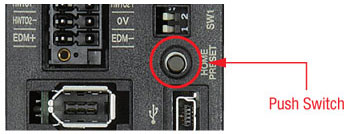

Home Setting Method*

The home position can be easily set by pressing a switch on the drivers surface, which is saved by the Mechanical Absolute Encoder. In addition, home setting is possible with the MEXE02 data setting software or external input signal.

Home position is easy to adjust by moving the motor to a desired position manually.

*Requires AZ Series Driver

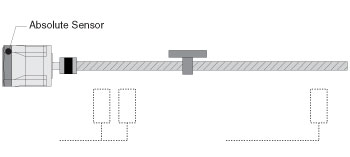

No External Sensors Required

Positional information is managed mechanically. External sensors such as home sensor and the limit sensor are not needed.

Reduced Cost

Sensor costs and wiring costs can be reduced, allowing for lower system costs.

Simple Wiring

Wiring is simplified and the degree of freedom for equipment design is increased.

Not Affected by Sensor Malfunctions

There is no concern about sensor malfunctions (when operating in environments filled with oil mist or filled with metal pieces due to metal processing), sensor failures or sensor wire disconnections.

Improved Return-to-Home Accuracy

Home position accuracy is increase because the return-to-home operation is performed regardless of any variations in home sensor sensitivity.

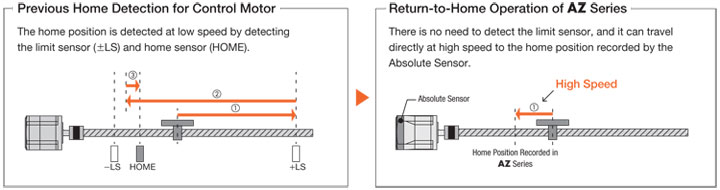

Shortened Reset Time - High Speed Return-to-Home

Because return-to-home is possible without an external sensor, return-to-home can be performed at high speed without taking the sensor sensitivity into account, allowing for a shortened machine cycle.

No Battery Required

No battery is required thanks to a mechanical-type sensor. Because positioning information is managed mechanically by the Mechanical Absolute Encoder, the positioning information can be preserved, even if the power turns off, or the cable between the motor and the driver is disconnected.

Reduced Maintenance

Because there is no battery that needs replacement, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control box.

Safe for Overseas Shipping

Normal batteries will self-discharge, so care must be taken when the equipment requires a long shipping time, such as when being sent overseas. The Mechanical Absolute Encoder does not require a battery, so there is no limit to how long the positioning information is maintained. In addition, there is no need to worry about various safety regulations, which must be taken into consideration when shipping a battery overseas.

Position Holding Even when the Cable between the Motor and Driver is Detached

Positioning information is stored within the Mechanical Absolute Encoder.

*Because the positioning information is stored in the Mechanical Absolute Encoder, the home position must be reset if the motor is replaced.

High Reliability

High Reliability is provided by using the control method unique to Oriental Motor that combines the merits of both open loop control and closed loop control.

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

In normal conditions, it operates synchronously with pulse commands under open loop control, and because of its compact size and high torque generation, it has excellent acceleration performance and response. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If a continuous overload is applied, an alarm signal is output. Also, when the positioning is completed, a signal is output. This provides high reliability.

No Tuning Required

Because it is normally operated with open loop control, positioning is still possible without gain tuning even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Holding the Stop Position

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

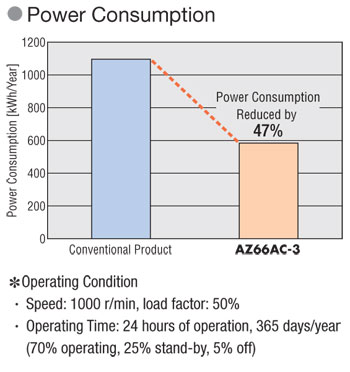

Energy Saving

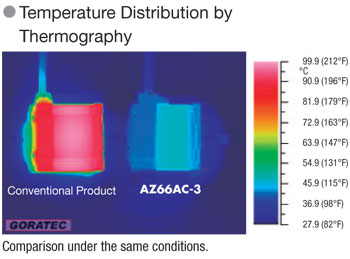

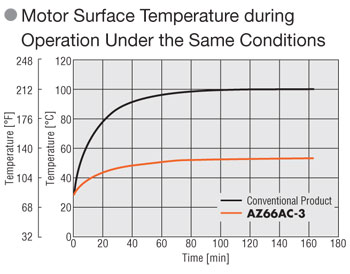

Heat generation is reduced thanks to the high efficiency motor, resulting in energy savings.

Lower Heat Generation

Heat generation by the motor has been significantly reduced through higher efficiency.

αSTEP Performance

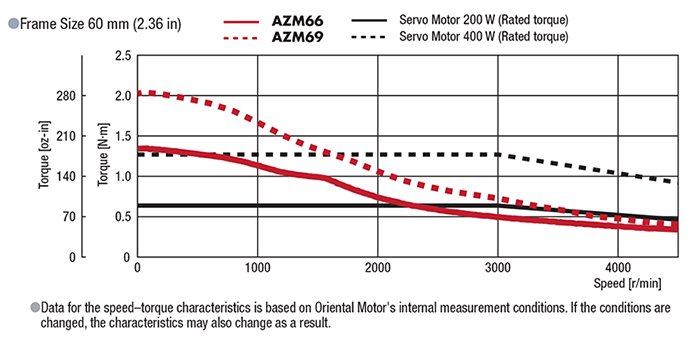

What is the Output of αSTEP?

"Rated Output" is not listed because αSTEP has no "rated speed". Refer to the graph below to compare rate torque of the αSTEP to Watts of of servo motor's rated output torque.

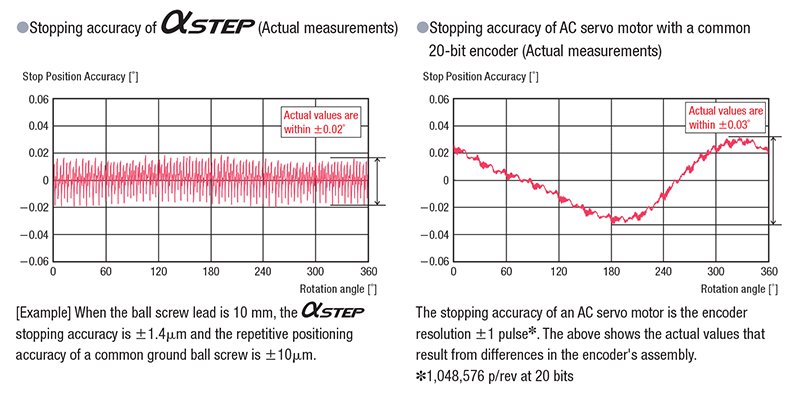

What is the Stopping Accuracy of αSTEP?

The stopping accuracy of a typical αSTEP is ±0.05° (under no load), which is equivalent to that of servo motors. The graphs below show the actual measured stopping accuracies when an αSTEP and an AC servo motor were rotated once.

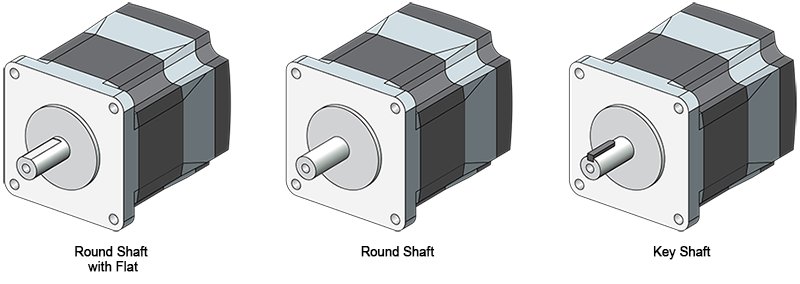

Standard Type Stepper Motors

The standard type AZ Series stepper motors are available in 3 output shaft types; Round Shaft*, Round Shaft with Flat and Key Shaft*.

*Round Shaft and Key Shaft only available on 1.65 in. (42 mm), 2.36 in. (60 mm) and 3.35 in. (85 mm) sizes.

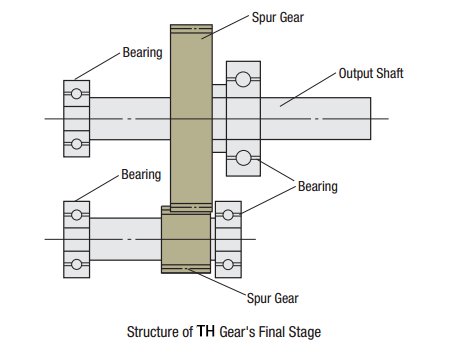

Taper Hobbed Gear Stepper Motors (TS)

- 1.65 in. (42 mm)

- 2.36 in. (60 mm)

- 3.54 in. (90 mm)

High Speed, Low Backlash Gears

This geared type is made with a simple spur gear design. The torque and speed have been improved.

Because of its high accuracy, this type has the same level of accuracy when compared to our tapered (TH) type without the added cost of tapering.

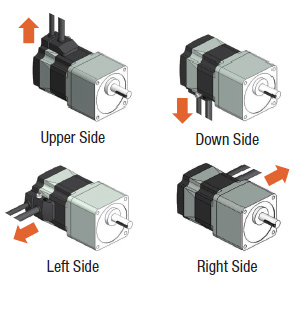

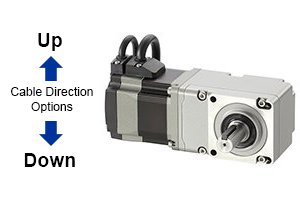

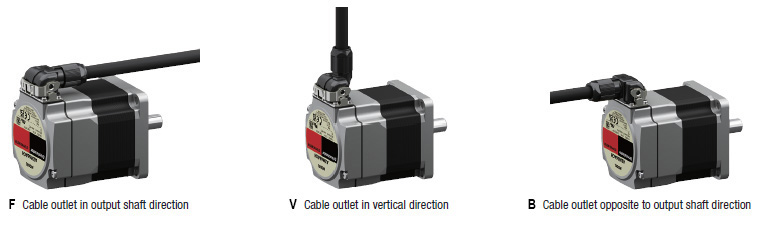

Cable outlet direction can be selected

There is a choice of four cable outlet directions in relation to the output shaft. Please contact technical support for the details.

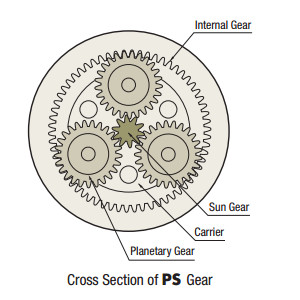

Planetary Gear Stepper Motors (PS)

- 1.10 in. (28 mm)

- 1.65 in. (42 mm)

- 2.36 in. (60 mm)

- 3.54 in. (90 mm)

High Torque, Low Backlash Gears

The PS gear mechanism is comprised primarily of a sun gear, planetary gears and an internal tooth gear. The planetary gears design allow for higher output torque.

There are gears inside used to distribute torque, which allows for higher torque than a spur gear design. The PS gear uses a higher accuracy gear design which provides for a lower backlash when compared to a spur gear design.

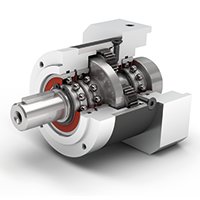

Neugart High Torque Planetary Gear Stepper Motor (PLE)

- 1.65 in. (42 mm)

- 2.36 in. (60 mm)

- 3.54 in. (90 mm)

Higher Torque, Lower Backlash Gears

The PLE Series gearhead employs optimized planetary gear mechanism and is composed of fully hardened gears. Sun gear and planetary gears are honed (precision final machining after heat treatment). This technology guarantees extremely high torque density, long life, low backlash, and so on.

*Motor and Gearhead ship separately and must be assembled using the included gasket and screws

Harmonic Planetary Gear Stepper Motors (HPG)

- 1.65 in. (42 mm)

- 2.36 in. (60 mm)

- 3.54 in. (90 mm)

High Accuracy, Non-backlash Gears

The HPG gear combine a harmonic and planetary gear speed-reduction mechanism allowing for high positioning accuracy, high permissible torque and high maximum instantaneous torque. The HPG Gears are available with a center shaft or surface mount to meet the needs of various applications.

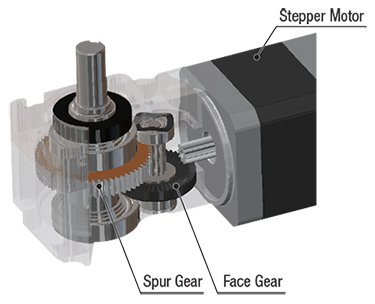

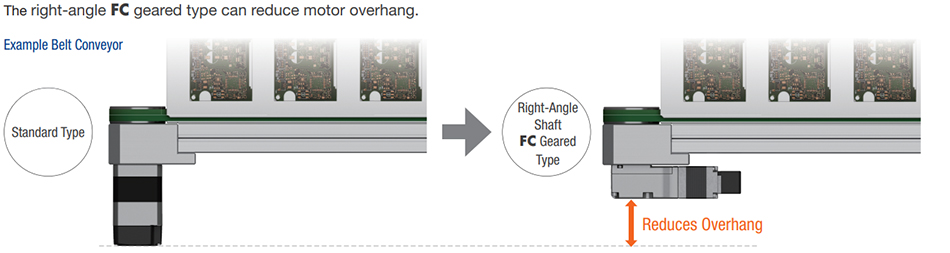

Right-Angle Face / Spur Gear (FC)

- 1.38 in. (35 mm)

- 1.65 in. (42 mm)

- 2.36 in. (60 mm)

The right-angle FC geared type is a compact orthogonal shaft geared motor made up of a disc-shaped gear (face gear) meshing with a spur gear. By combining it with an AZ series motor, high precision, high strength and space savings is possible at an affordable price.

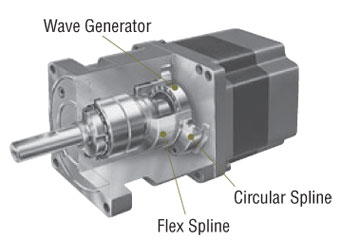

Harmonic Gear Stepper Motors (HS)

- 1.18 in. (30 mm)

- 1.65 in. (42 mm)

- 2.36 in. (60 mm)

- 3.54 in. (90 mm)

High Accuracy, Non-Backlash Performance Gears

The mechanical life, permissible torque and maximum torque are improved (compared with conventional models).

Improved Rate Life (Twice the length of conventional models)

The rate life has been increased from 5,000 hours (conventional model) to 10,000 hours.

[Except for 1.65 in. (42 mm) frame size]

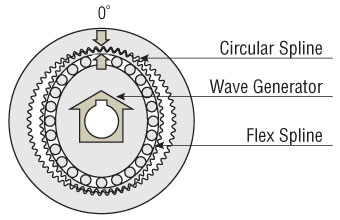

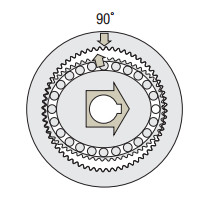

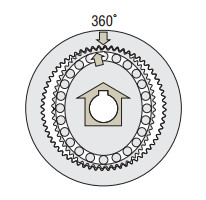

The harmonic gear utilizes the metal’s electrodynamics property. It is comprised of three basic components, a wave generator, flex spline and circular spline.

Rotating the wave generator (input) clockwise while keeping the circular spline fixed in position will subject the flax spline to elastic deformation, causing a gradual shift in the point of engagement between the circular spline and flex spline.

When the wave generator completes one revolution, the flex spline has rotated two fewer teeth than the circular spline has, resulting in the movement of the flex spline for the difference in the tooth count (two teeth) in the opposite direction of the wave generator's rotation (i.e. counterclockwise). This movement translates into output, thereby reducing the speed.

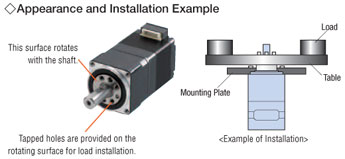

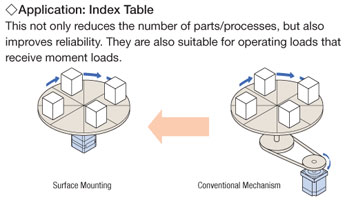

Surface Installation of Load

The harmonic geared type permits installation of load directly on the rotating surface integrated with the shaft. [Expect for geared stepper motors with a frame size of 3.54 in. (90 mm)].

Cable Type

Standard Cable Type

The standard AZ Series motor uses motor cables to connect to the driver.

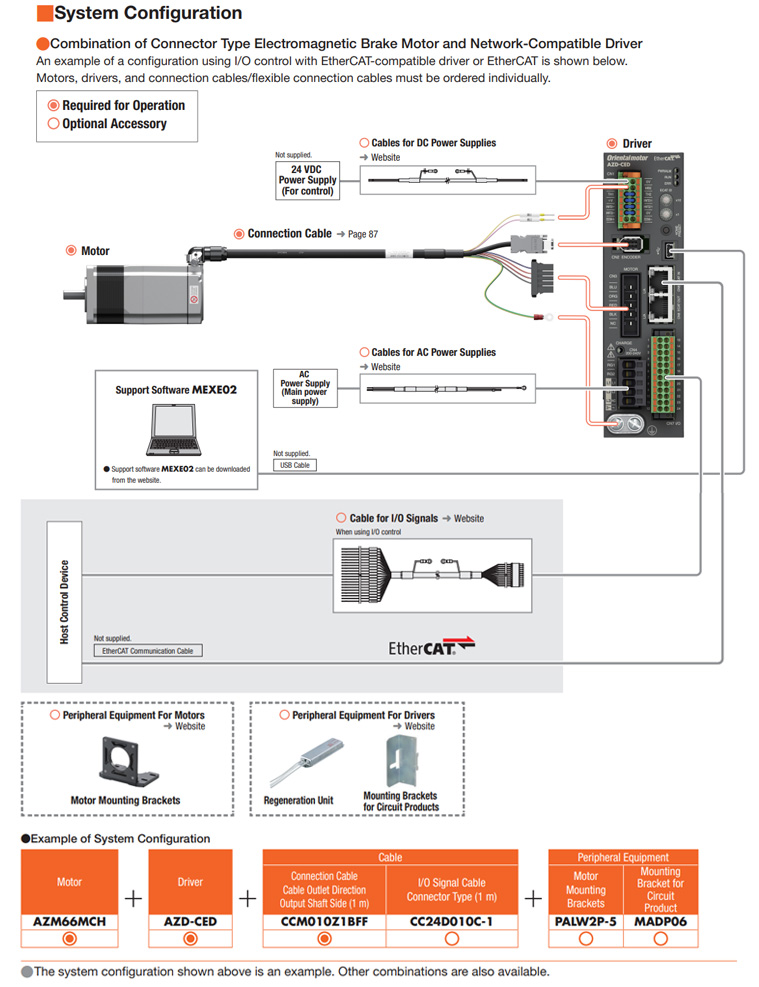

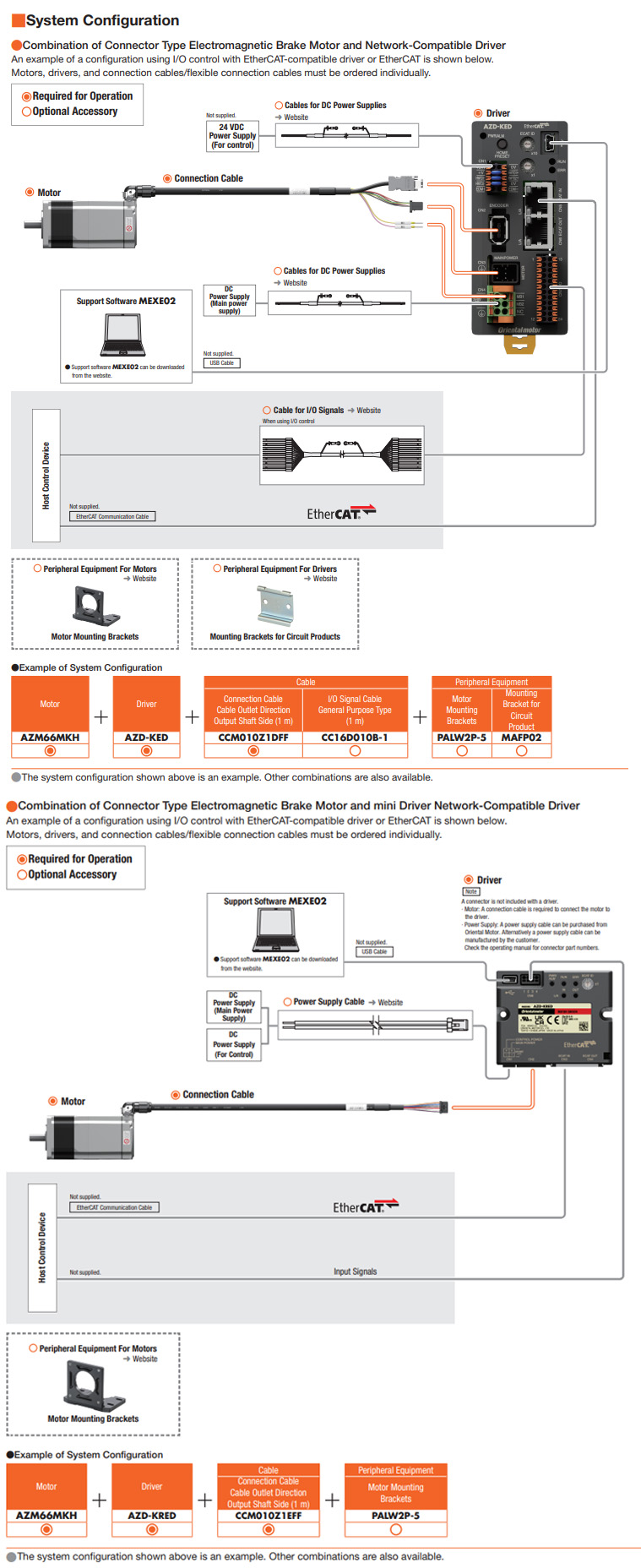

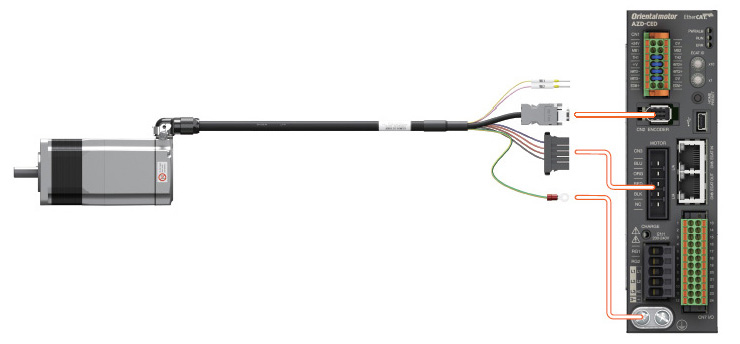

Connector Type

Direct Connection Motor to Driver

One cable locking connector allows for a maximum of 10 m (32.8 ft.) between the motor and driver with the same motor performance specifications as our standard AZ Series.

Current motor cable connections not compatible with AZ Mini DC or Multi-Axis Drivers.

The one motor and driver cable includes the power line to the motor, signal line, electromagnetic brake line (brake motor type) and the ground wire for easy motor connection with no separate connection required for extension cables.

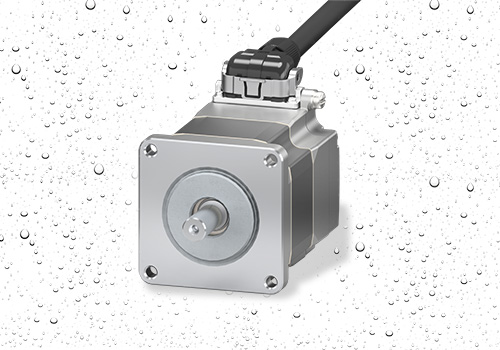

Degree of Protection IP66

With the degree of protection IP66, it is highly dustproof and can be used in environments where it may be exposed to water droplets.

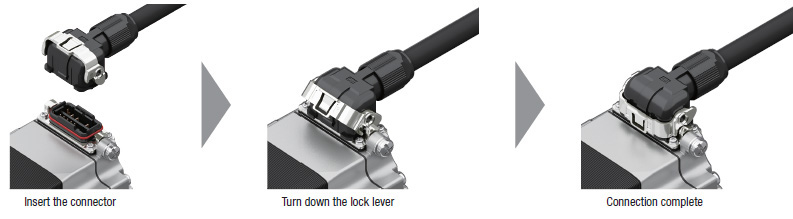

A Lock Lever Connector is Used To Ensure Connection

Connecting the cable is easy due to the lock lever that does not require screws.

Three Cable Outlet Directions Can be Selected

The product line contains multiple cable outlet directions. This allows for choosing the cable type based on the cable outlet direction required.

Electromagnetic Brake Option

- 1.65 in. (42 mm)

- 2.36 in. (60 mm)

- 3.35 / 3.54 in. (85 / 90 mm)

These products have built-in power-off activated electromagnetic brakes. When power is accidentally cut off due to a blackout or other unexpected events, the electromagnetic brake holds the load in position to prevent it from dropping or moving. Also, when the motor is at standstill, it can be held by the electromagnetic brake. It is possible to suppress the heat generated from the motor by turning off the motor current.

AZ Series AC Input Drivers

The αSTEP AZD (AC Input) Drivers offers superior high speed performance, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. Advanced operation and function control is included through our MEXE02 software (free download). The αSTEP AZD (AC Input) Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Emergency Torque Off Function

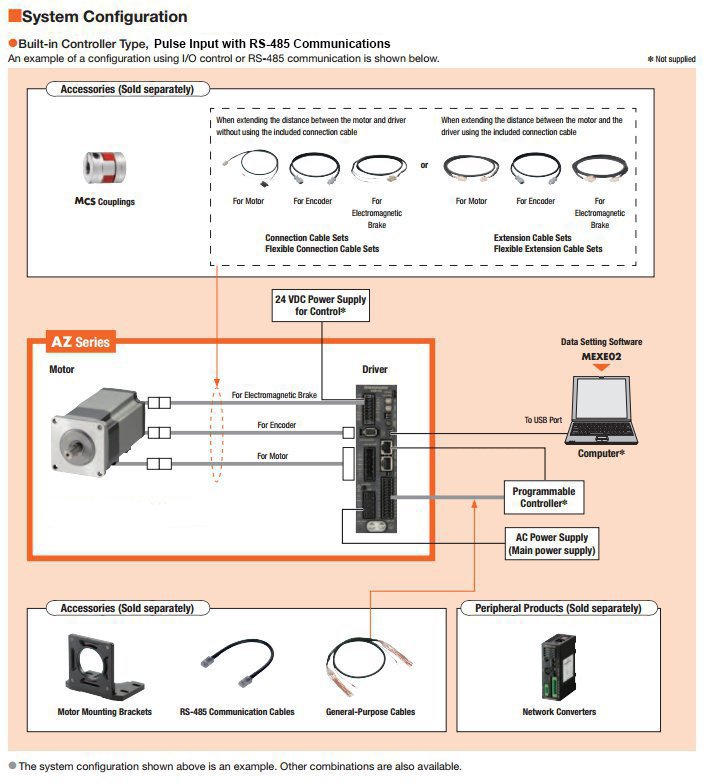

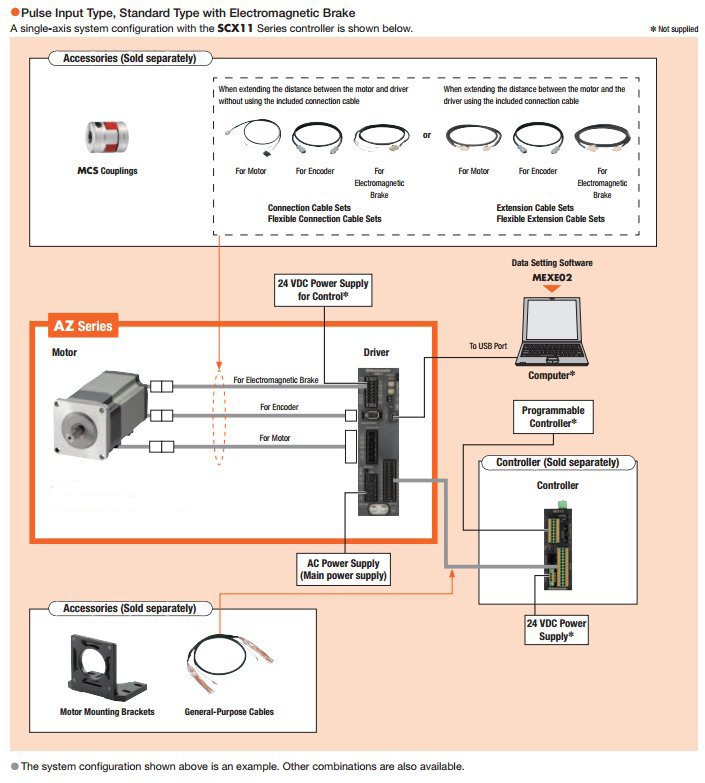

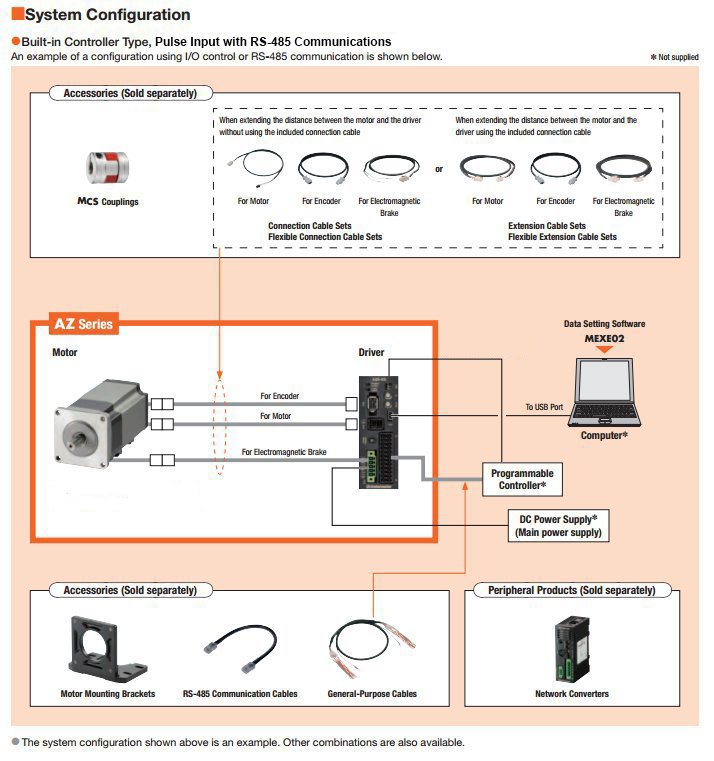

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with αSTEP AZ Series Motors (AC Input)

![]()

AZ Series DC Input Drivers

The αSTEP DC Input Drivers offer 24/48 VDC input voltage, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. The αSTEP AZD-K (DC Input) can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- 24/48 VDC

- For use with αSTEP AZ Series Motors (DC Input)

![]()

AZ Series mini DC Input Drivers

The AZ Series mini Driver works with a variety of αSTEP AZ Series, DC input products. This driver can be controlled using EtherCAT, PROFINET, EtherNet/IP, RS-485 communication, or Pulse Input Type with RS-485 Communication and daisy chained to maximize design and space and improve installation time. The mini Driver is also designed to be close to the motor, making it ideal for Robotic type applications.

The elimination of switches and I/O connectors allows for a compact and lightweight design. Utilizes the MEXE02 Support Software, available for free download.

- Built-in Protective Functions

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- 24/48 VDC

- For use with αSTEP AZ Series Motors (DC Input)

![]()

Mounting Bracket for AZ mini Driver

Mounting Bracket for AZ mini Driver.

*Connector-Type Only

Item |

Frame Size |

42 mm |

|

60 mm |

0.2 m connection cabe for AZ mini Driver to AZ connector type motor is recommended.

AZ Series Multi-Axis Controller / Driver (EtherCAT)

A multi-axis controller that supports EtherCAT communication.Compatible with the CiA402 drive profile. It can be connected to the AZ Series DC input motors and electric actuators.

2-axis, 3-axis and 4-axis driver connections are available.

- 24/48VDC

- Multi-Axis Motor Connection Cables required*

![]()

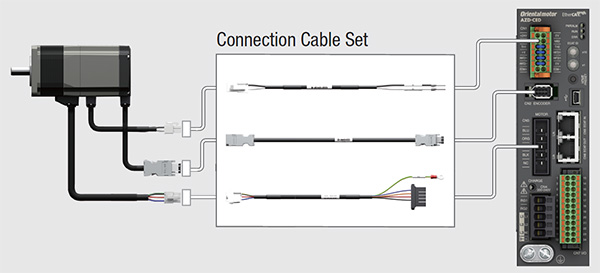

Cables for Single-Axis Drivers (Cable Type)

These cables are used to connect or extend the distance between the cable type motor and single-axis driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

*Multi-Axis Controller / Driver requires different cables

Connector Type Cables for Single-Axis Drivers

These cables are used to connect or extend the distance between the connector type motor and single-axis driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Connector Type Cables for DC Input mini Driver

These cables are used to connect the connector type motor and mini driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Rotary Encoders

Small, thin, and lightweight stand-alone rotary encoders with an outer diameter of ϕ30 mm can be installed in tight spaces.

Flexible Couplings

This three-piece coupling adopts an aluminum alloy hub and a resin spider. The simple construction ensures that the high torque generated by a gear motor can be transmitted reliably. The proper elasticity of the spider suppresses motor vibration.

Mounting Brackets

Mounting brackets are convenient for installation and securing a stepper motor or geared stepper motor.

MRC Robot Controller

The MRC01 robot controller supports easy programming and control of in-house designed custom built robots with 3 simple steps: "Initial Setup", "Operating Programming" and "Operational Checking".

Network Gateways

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Connection to Oriental Motor's network compatible products is completed with one RS-485 communication cable.

- Compatible Networks:

CC-Link, MECHATROLINK-II, MECHATROLINK-III, EtherCat

![]()

![]()

![]()

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.