EAS Series Closed Loop Linear Slides

EZS Closed Loop AZ Series Absolute Encoder Electric Linear Slides

Compact, high-rigidity electric linear slides with simple, dust-resistant structure providing the high response, low vibration and hunting-free operation of a stepper motor in an electric linear slide. A wide variety of options to suit the equipment space and environment, including straight type and reversed motor type. Being compact and rigid, this series is effective in supporting large transportable mass.

- Equipped with battery-free absolute encoder

- Positioning information can be known without a sensor

- High reliability using closed loop control

- Reduced motor heat and reduced energy consumption through high efficiency design

- Electromagnetic Brake available

- AC or DC Input

- AZ Series Drivers required (sold separately)

Mechanical Absolute Encoder

Linear Slide Lineup

Type |

Power Input |

Options |

Max. Trans. Mass* (Horizontal) (kg) |

Max. Speed* |

Stroke |

EZS3 |

6 mm or 12 mm Lead Electromagnetic Brake |

~7.5 or ~15 |

800 or 400 |

50 ~ 700 |

|

600 or 300 |

|||||

EZS3 |

Right or Left Motor Mount 6 mm or 12 mm Lead Electromagnetic Brake |

~7.5 or ~15 | 800 or 400 |

50 ~ 700 | |

600 or 300 |

|||||

EZS4 |

6 mm or 12 mm Lead Electromagnetic Brake |

~15 or ~30 |

800 or 400 |

50 ~ 700 |

|

600 or 300 |

|||||

EZS4 |

Right or Left Motor Mount 6 mm or 12 mm Lead Electromagnetic Brake |

~15 or ~30 | 800 or 400 |

50 ~ 700 | |

600 or 300 |

|||||

EZS6 |

6 mm or 12 mm Lead Electromagnetic Brake |

~30 or ~60 |

800 or 400 |

50 ~ 850 |

|

600 or 300 |

|||||

EZS6 |

Right or Left Motor Mount 6 mm or 12 mm Lead Electromagnetic Brake |

~30 or ~60 | 800 or 400 |

50 ~ 850 | |

600 or 300 |

Repetitive Positioning Accuracy = ±0.02 mm

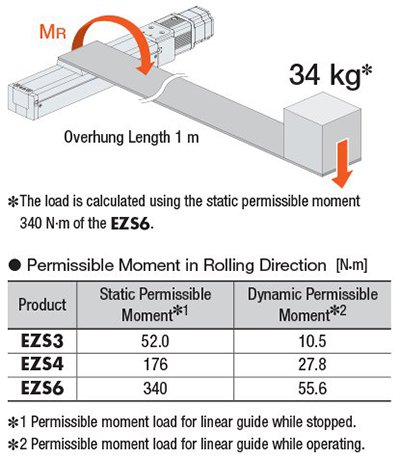

Dynamic Permissible Moment =

- EZS3 - MP: 4.2 N·m, MY: 4.2 N·m, MR: 10.5 N·m

- EZS4 - MP: 8.0 N·m, MY: 8.0 N·m, MR: 27.8 N·m

- EZS6 - MP: 45.7 N·m, MY: 37.5 N·m, MR: 55.6 N·m

Static Permissible Moment =

- EZS3 - MP: 26.4 N·m, MY: 26.4 N·m, MR: 52 N·m

- EZS4 - MP: 51.2 N·m, MY: 42.5 N·m, MR: 176.0 N·m

- EZS6 - MP: 290.0 N·m, MY: 187.0 N·m, MR: 340.0 N·m

*Max. Transportable Mass (Horizontal) varies by Lead (6 mm = High Value, 12 mm = Lower Value)

*Max. Speed varies by Lead (6 mm = Lower Value, 12 mm = Higher Value)

Linear Slides

High Rigidity / High Accuracy

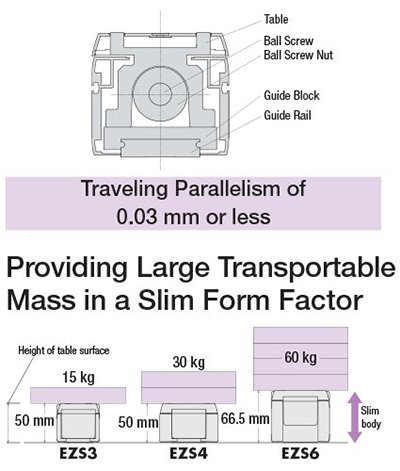

Despite the small size, high permissible moment loads have been achieved by using a highly rigid guide.

High Rigidity and High Accuracy Guide

The LM Guide™ from THK is used as the guide hardware. It is a thin, stainless steel guide that can withstand high moment loads. The guide also has excellent traveling parallelism, which has been reduced to 0.03 mm or less.

High Permissible Moment

This series is compact yet effective in handling high moment loads.

Space-Saving

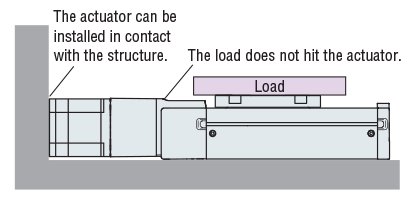

Maximum use of space is possible because the equipment doesn't interfere with the load.

Equipment can be installed in contact with surrounding structures.

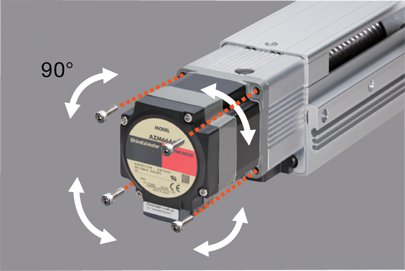

Variable Cable Outlet Direction

The motor attachment direction can be changed to any of 4 directions*, allowing the cable outlet to be changed to best suit the installation location.

*3 directions for reversed motor types.

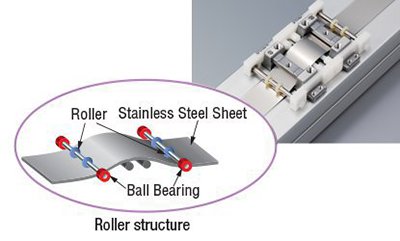

Simple Dust-Resistant Structure

Through the use of a stainless steel, simple dust-resistant structure, simple dust-resistant infiltration of foreign objects is prevented and dust generation is also controlled.

Low Dust-Generated Roller Structure

A low dust-generation roller structure has been built into the table which provides rolling contact with the stainless steel sheet, thus preventing the generation of abrasive particles. This not only controls the generation of dust, but also improves the durability of the stainless steel sheet.

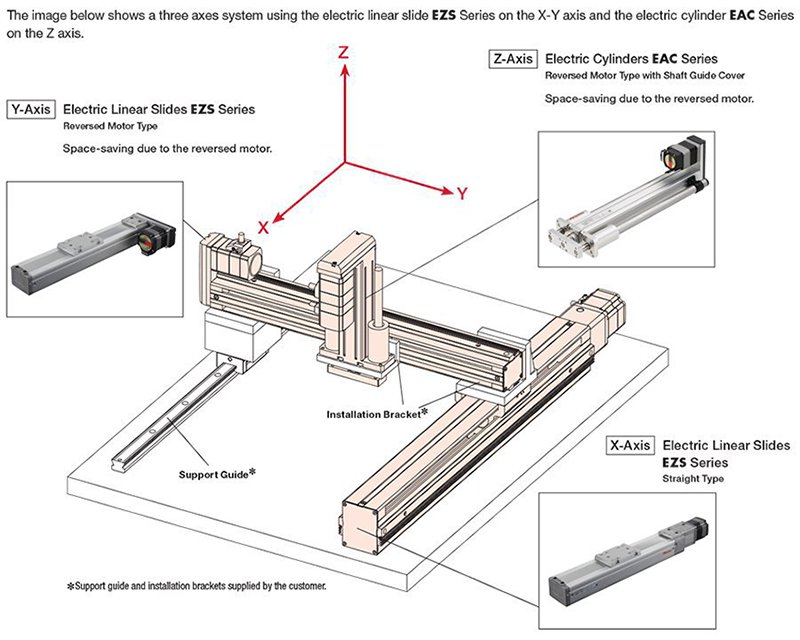

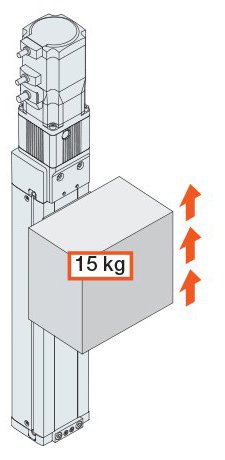

Application Example

High Speed Driving

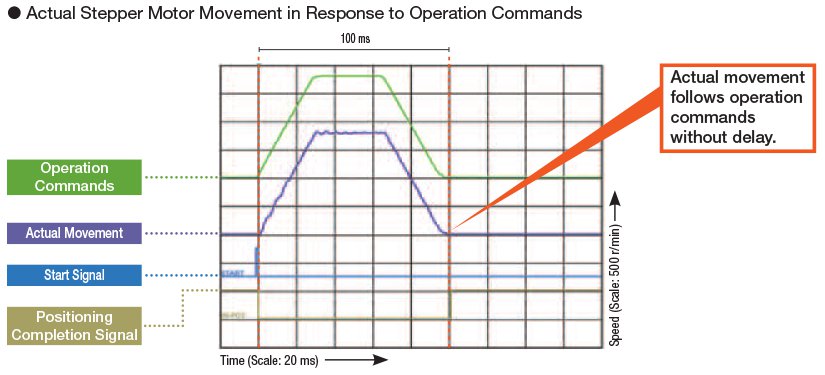

High Response

By utilizing the high response of the stepper motor, short distances can be covered quickly. Movement follows commands without delay.

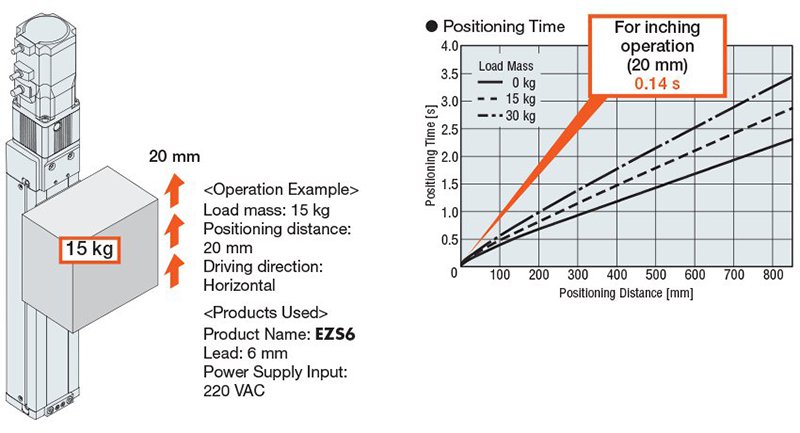

Short-Distance High-Speed Driving Even with Heavy Loads

By combining the high response characteristic of stepper motors with a highly rigid guide, high-speed operation even under heavy loads becomes possible.

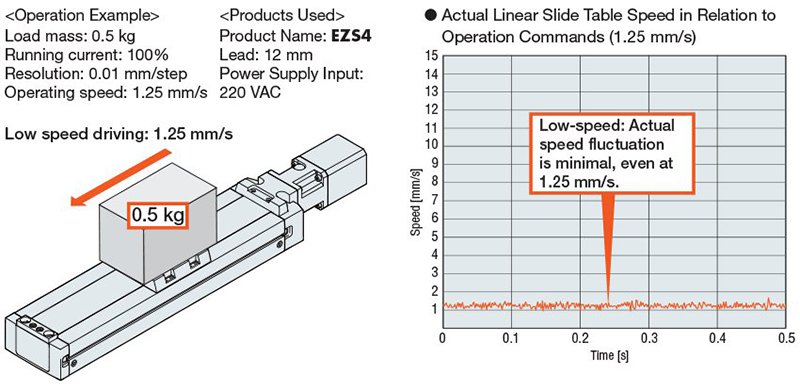

Smooth Movement Even at Low Speeds

Reduced vibration and smooth movement is possible thanks to the standard microstep drive system and smooth drive functions*.

*The smooth drive function automatically microsteps based on the same traveling amount and speed used in the full step mode, without changing the pulse input settings.

No External Sensors Required

Because the absolute motor sensor (ABZO) is built-in, there's no need for a battery to store the positioning information, or for a home sensor, or external sensors or any other external sensors.

- Cost Reduction

- Simplified Wiring

- Not Affected by Sensor Malfunctions

- Improved Return-to-Home Accuracy

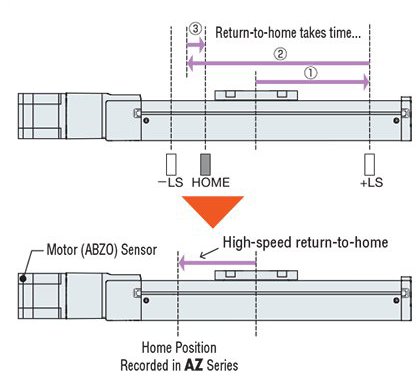

High-Speed Return-to-Home

Regular Return-to-Home

With the use of limit sensors and home sensors to detect the home point at low speeds, return-to-home is time consuming.

Return-to-Home Operation of the αSTEP AZ Series

Without the need to detect using limit sensors or the home sensor, the equipment can travel directly at high speed of the home position recorded by the motor sensor.

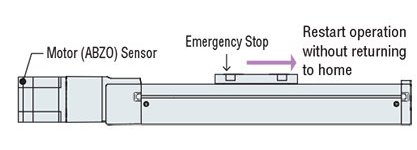

Return-to-Home Not Required (For built-in controller type)

Since the position information is known even when the power supply is turned off, operation can resume without return-to-home after an emergency stop or power outage.

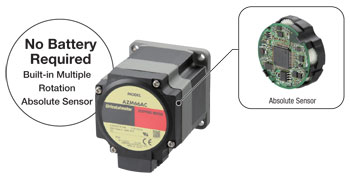

Mechanical Type Absolute Encoder Motor

Advanced Technology at Affordable Prices

Oriental Motor has developed and patented a compact, low-cost, battery-free mechanical type absolute sensor. The AZ Series is available at affordable prices and can contribute to improved productivity and cost reductions.

Mechanical-Type Encoder (No Battery Required)

A mechanical sensor composed of multiple gears is employed. Positioning information is detected by recognizing the angle of the individual gears. As a result, it does not require a battery.

Multiple-Rotation Absolute System*

Absolute position detection is possible with ±900 rotations (1800 rotations) of the motor shaft from the home position.

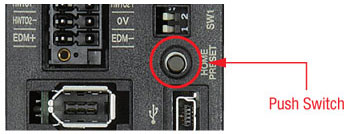

Home Setting Method*

The home position can be easily set by pressing a switch on the drivers surface, which is saved by the Mechanical Absolute Encoder. In addition, home setting is possible with the MEXE02 data setting software or external input signal.

Home position is easy to adjust by moving the motor to a desired position manually.

*Requires AZ Series Driver

No Battery Required

No battery is required thanks to a mechanical-type sensor. Because positioning information is managed mechanically by the Mechanical Absolute Encoder, the positioning information can be preserved, even if the power turns off, or the cable between the motor and the driver is disconnected.

Reduced Maintenance

Because there is no battery that needs replacement, maintenance time and costs can be reduced.

Unlimited Driver Installation Possibilities

Because there is no need to secure space for battery replacement, there are no restrictions on the installation location of the driver, improving the flexibility and freedom of the layout design of the control box.

Safe for Overseas Shipping

Normal batteries will self-discharge, so care must be taken when the equipment requires a long shipping time, such as when being sent overseas. The Mechanical Absolute Encoder does not require a battery, so there is no limit to how long the positioning information is maintained. In addition, there is no need to worry about various safety regulations, which must be taken into consideration when shipping a battery overseas.

Position Holding Even when the Cable between the Motor and Driver is Detached

Positioning information is stored within the Mechanical Absolute Encoder.

*Because the positioning information is stored in the Mechanical Absolute Encoder, the home position must be reset if the motor is replaced.

High Reliability

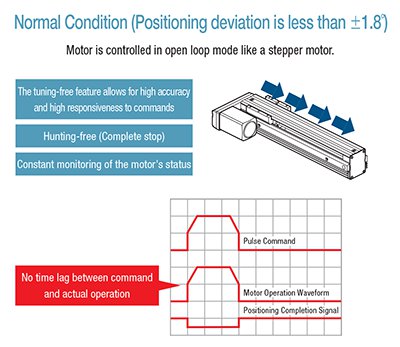

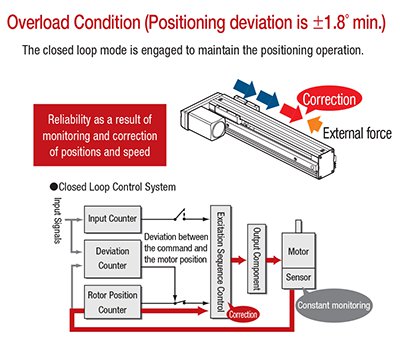

High Reliability is provided by using the control method unique to Oriental Motor that combines the merits of both open loop control and closed loop control.

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

In normal conditions, it operates synchronously with pulse commands under open loop control, and because of its compact size and high torque generation, it has excellent acceleration performance and response. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If a continuous overload is applied, an alarm signal is output. Also, when the positioning is completed, a signal is output. This provides high reliability.

No Tuning Required

Because it is normally operated with open loop control, positioning is still possible without gain tuning even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Holding the Stop Position

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

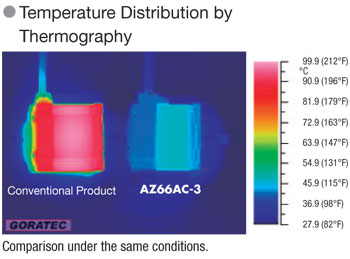

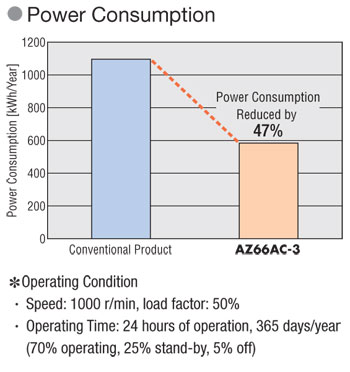

Energy Saving

Heat generation is reduced thanks to the high efficiency motor, resulting in energy savings.

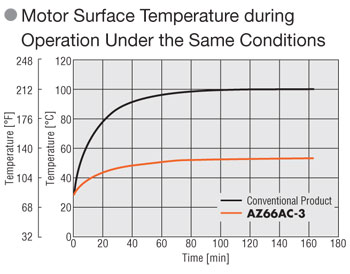

Lower Heat Generation

Heat generation by the motor has been significantly reduced through higher efficiency.

αSTEP Control System

Hybrid Control System

The hybrid control system constantly monitors the motors position allowing for the benefits of performance from "open loop" control while providing the assurance of "closed loop " performance.

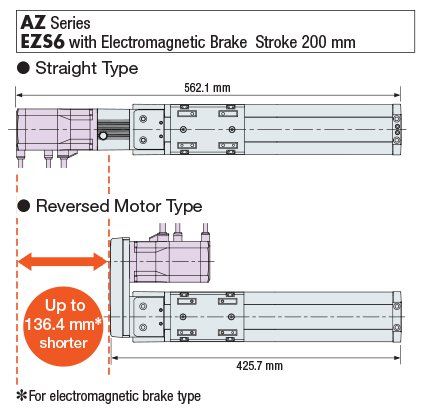

Reversed Motor Type

With overall lengths up to 136.4 mm shorter compared to the straight type, reversed motor types can contribute to equipment space-saving.

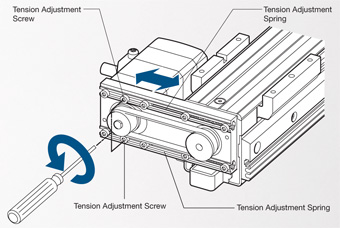

Simple Maintenance for Reversed Motor Type

Maintainability has been improved by using Oriental Motor's unique belt tension adjustment mechanism and through the standardization of maintenance parts based on the AZ Series.

Thanks to Oriental Motor's unique belt tension adjustment mechanism, belt replacement is easy.

If the screw is loosened, the belt tension is adjusted to an appropriate value by the force of the spring.

Electromagnetic Brake

Vertical operation is possible with electromagnetic brake. The load position can be held when the power is cut off. Since the work will not fall in case of power failure or disconnection, you can safely use equipment in which the work moves vertically.

AZ Series AC Input Drivers

The αSTEP AZD (AC Input) Drivers offers superior high speed performance, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. Advanced operation and function control is included through our MEXE02 software (free download). The αSTEP AZD (AC Input) Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Emergency Torque Off Function

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- Single-Phase 100-120 VAC or Single-Phase/Three-Phase 200-240 VAC

- For use with αSTEP AZ Series Motors (AC Input)

![]()

AZ Series DC Input Drivers

The αSTEP DC Input Drivers offer 24/48 VDC input voltage, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. The αSTEP AZD-K (DC Input) can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input, Pulse Input with RS-485 Communications, Built-in Controller (Network), EtherCAT, EtherNet/IP™ or PROFINET Types

- 24/48 VDC

- For use with αSTEP AZ Series Motors (DC Input)

![]()

Multi-Axis Controller / Driver (EtherCAT)

A multi-axis controller that supports EtherCAT communication.Compatible with the CiA402 drive profile. It can be connected to the AZ Series DC input motors and electric actuators.

2-axis, 3-axis and 4-axis driver connections are available.

- 24/48VDC

![]()

Cables (*Required)

These cables are used to connect or extend the distance between the motor and driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Dual Axis Installation Bracket

These are dedicated mounting brackets for using electric linear slides along two axes.

*For use with Straight Type Only.

Cable Holder

This is the most suitable product for protecting or guiding the cables being used in dual and triple axis combinations. This product can be combined with the Dual Axis Installation Bracket.

Sensor Set

The sensor set consists of three sets of a sensor, a sensor installation bracket and a flexible sensor cable with connector 6.6 ft. (2 m) and 1 shield plate. The screws needed for installation are also included.

Item # |

Sensor Output |

PNP |

|

NPN |

Rotary Encoders

Small, thin, and lightweight stand-alone rotary encoders with an outer diameter of ϕ30 mm can be installed in tight spaces.

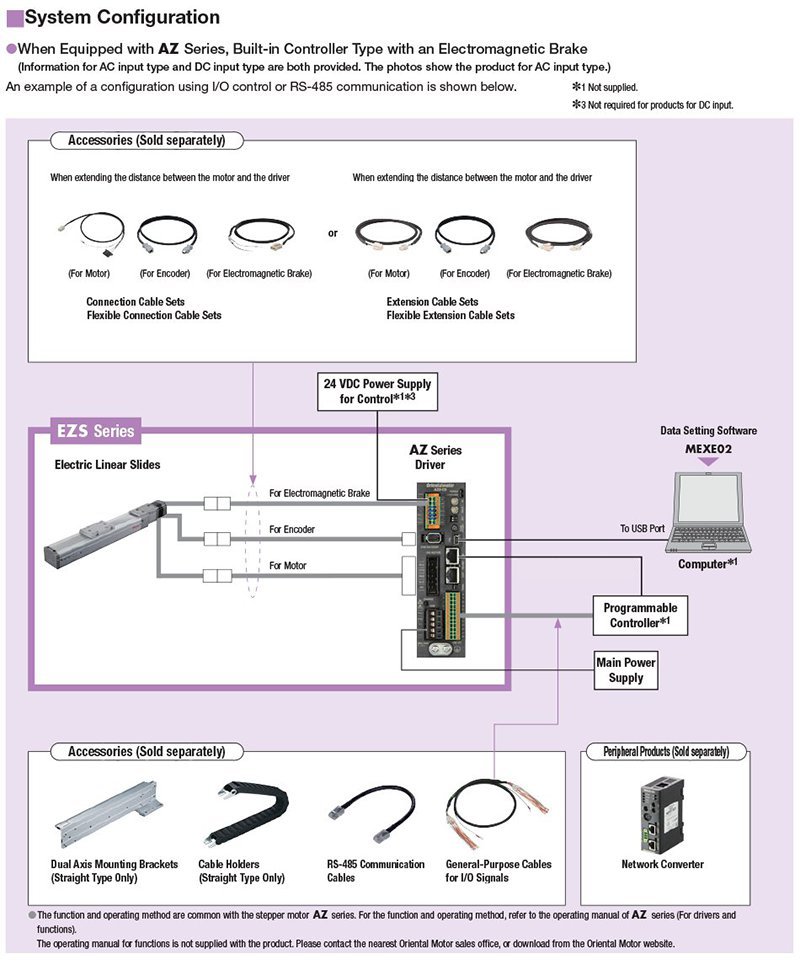

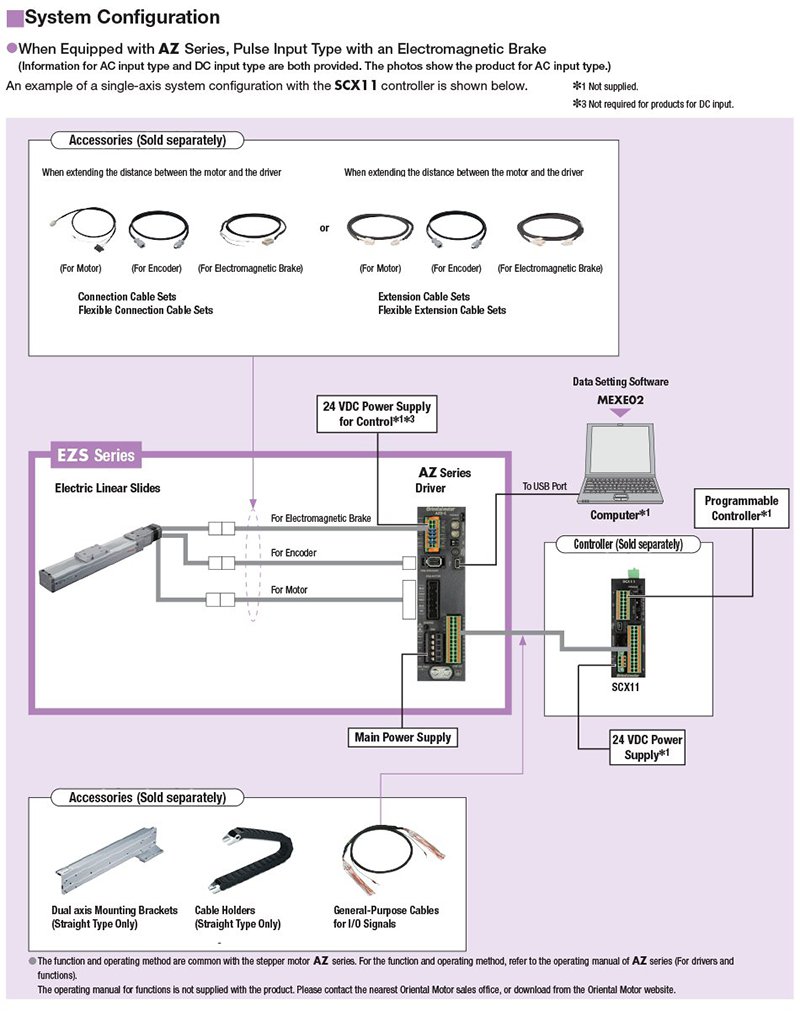

System Configuration

An example of a configuration using Network Communications or RS-485 communication is shown below.

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.