EtherCAT Multi-Axis Controllers / Drivers

αSTEP Hybrid Step-Servo

AZ Series EtherCAT Multi-Axis Controllers / Drivers (DC Input)

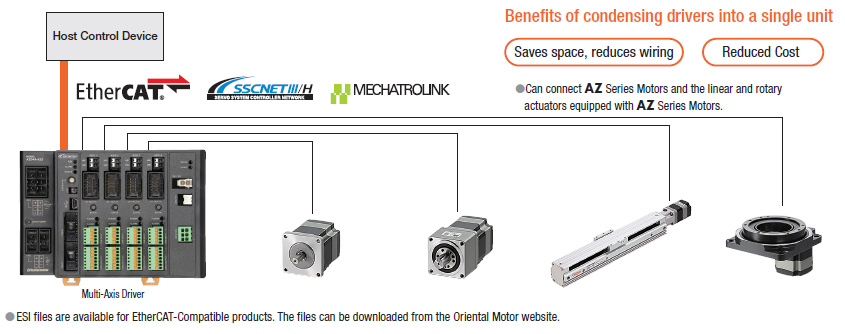

A multi-axis controller that supports EtherCAT communication.Compatible with the CiA402 drive profile. It can be connected to the AZ Series DC input motors and electric actuators.

2-axis, 3-axis and 4-axis driver connections are available.

- 24/48VDC

- Works with AZ Series DC Input stepper motors and actuators

- Multi-Axis Motor Connection Cables required

![]()

![]()

![]()

*Call for support with SSCNETIII/H or Mechatrolink, 1-800-GO-VEXTA (468-3982)

Product Lineup

Item |

Network |

Power Supply |

Control Power Supply |

EtherCAT |

24/48 VDC |

24 VDC |

|

EtherCAT |

24/48 VDC |

24 VDC |

|

EtherCAT |

24/48 VDC |

24 VDC |

Space-Saving and Low-Cost Multi-Axis Controller / Driver (Max. 4 Axes)

AZ Series Multi-Axis Drivers

A multi-axis driver that supports EtherCAT communication. Compatible with the CiA402 drive profile. It can be connected to the AZ Series DC input motors and electric actuators. 2-axes, 3-axes and 4-axes driver connections are available.

ESI File

An ESI file is provided so that EtherCAT-compatible products can be used more easily. For questions about connections to Omron PLCs, please contact OMRON Corporation. An EtherCAT connection guide is available.

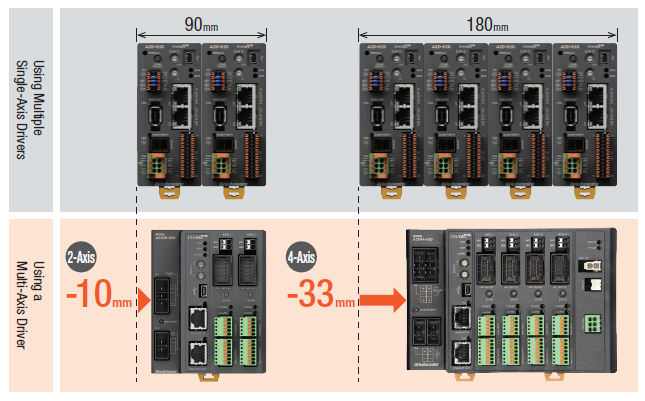

Multi-Axis Drivers (2-Axis Type, 4-Axis Type) are compact and save space by aligning Single-Axis Drivers

Multi-Axis Drivers can reduce installation space by aligning network-compatible Single-Axis Drivers.

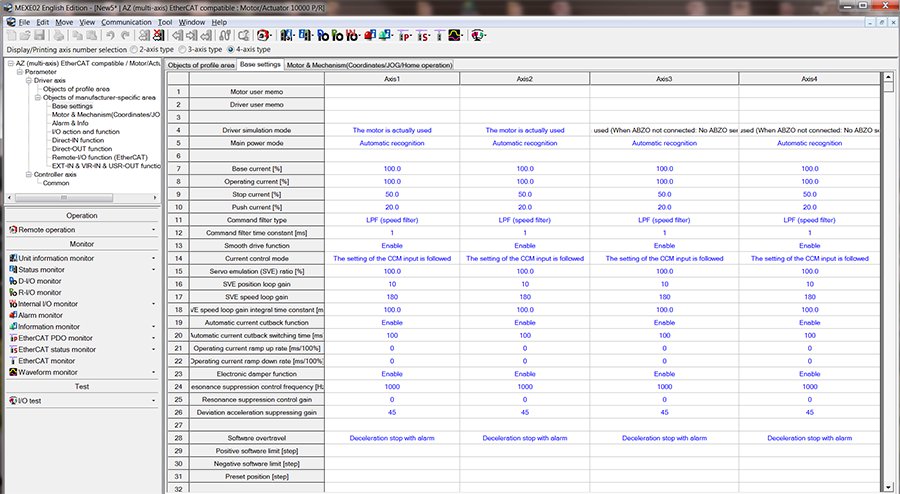

Extended Functions with MEXE02 Support Software

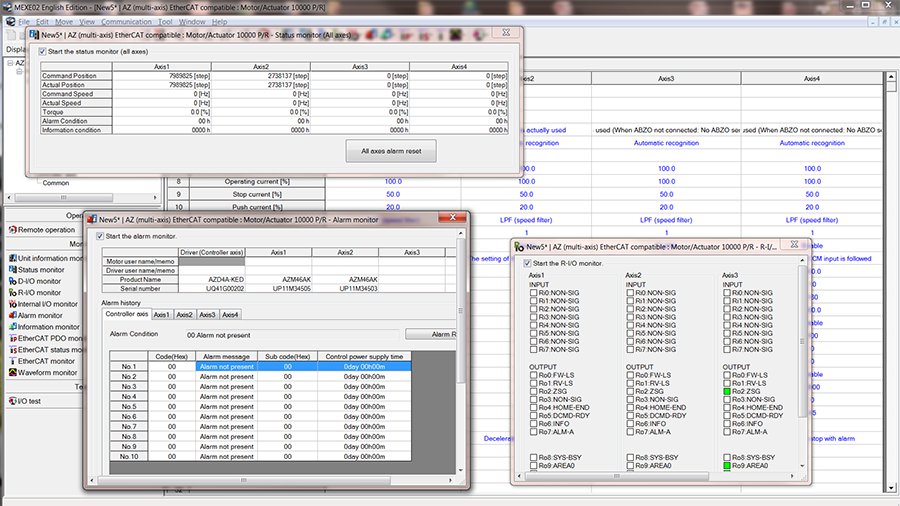

Monitoring Functions

You can monitor the status of all axes at once.

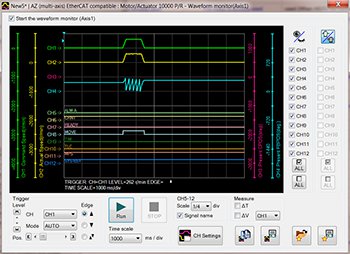

Waveform Monitoring

The operating status of the motor (such as command speed and feedback speed), can be checked by an oscilloscope-like image. This can be used for equipment start-up and adjustment.

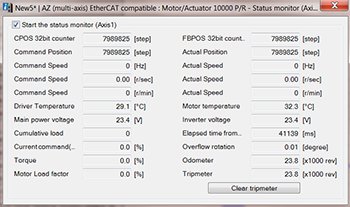

Status Monitor

In addition to monitoring operating speed, motor driver temperature and load factor, you can also monitor total rotation amount from the start of use.

For each item, you can set up to output signals arbitrarily, so it is effective for efficient maintenance.

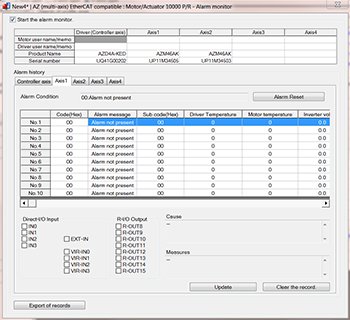

Alarm Monitoring

When an abnormality occurs, the details of the abnormality and the solution can be checked. Because the solution can be checked it is possible to respond to abnormalities quickly.

Multi-Monitoring Support

Multiple setting screens such as data setting, test driving, monitoring etc. can be opened simultaneously in separate screens and used. It is easy to start up and adjust the equipment.

Test Function

It is a function that allows you to operate the motor independently or check connection with the host system.

By utilizing it at the time of device start-up, it will shorten the time.

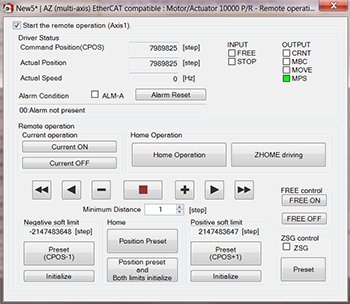

Remote Operation

Data setting software can be used to perform the home setting and also drive the motor. This can be used for teaching or test drive purposes.

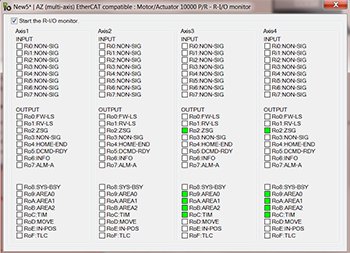

I/O Test

The status of the I/O wired to the driver can be checked on a computer. This can be used for post-wiring I/O checks or I/O checks during operation.

Parameter Settings

You can set parameters directly without going through the network. Also, you can set each axis without replacing the cable.

AZ Series Products

Eliminate Extra Sensors with a Battery-Free Absolute System

The αSTEP AZ Series Mechanical Absolute Encoder is available as a leading closed loop, battery free absolute motion solution sold as a Stepper Motor + Driver or Linear Actuator + Driver allowing for absolute, battery free, advanced performance across a wide range of applications.

AZ Series Closed Loop Stepper Motors (DC Input)

The AZ Series offers high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires AZ Series Driver.

- Battery-Free, Mechanical Absolute Encoder

- Closed Loop Performance, No Hunting or Gain Tuning

- DC Input Types

- Wide Range of Gear Types for Inertia Matching & Higher Torque

- Electromagnetic Brake Type Available

Control Options - Support Software

MEXE02 Support Software.

*A standard USB to mini B cable is used to connect all drive options to the computer (sold by a third party).

Multi-Axis Motor Connection Cables (required)

These motor connection cables are required when connecting to the Multi-Axis Controller / Driver.

Power Supply Cables

These cables connect the Power Supply to the Multi-Axis Controller / Driver.

Type |

Product |

Main Power |

|

Control Power |

Regeneration Unit

Use this unit if your application involves vertical movement or a large inertia load.

*Cannot be used with 2-axis drivers.

Type |

Product |

Regeneration Unit |

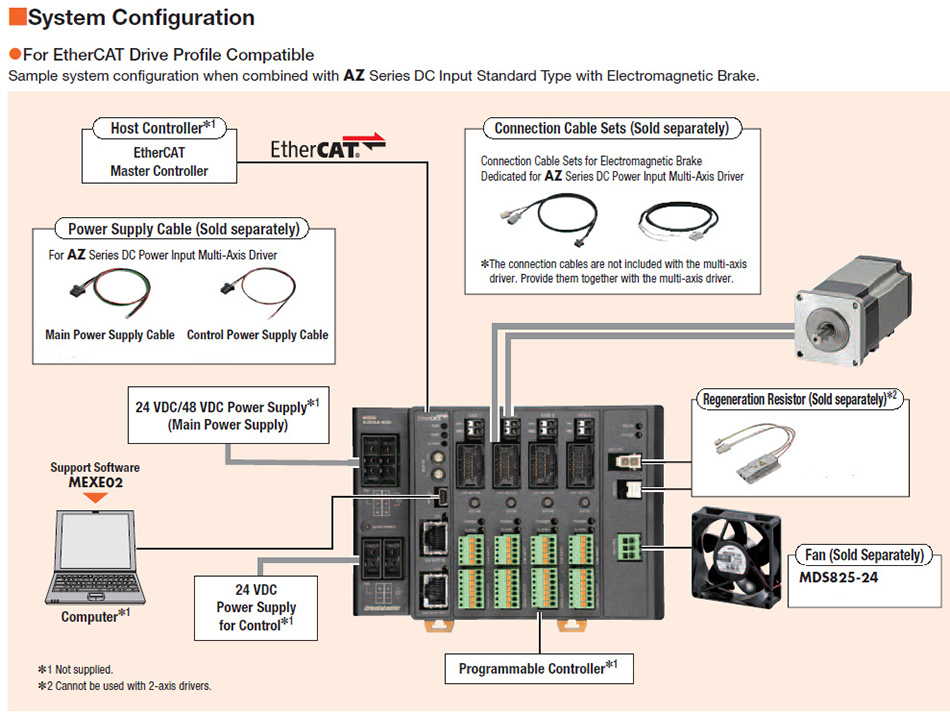

System Configuration

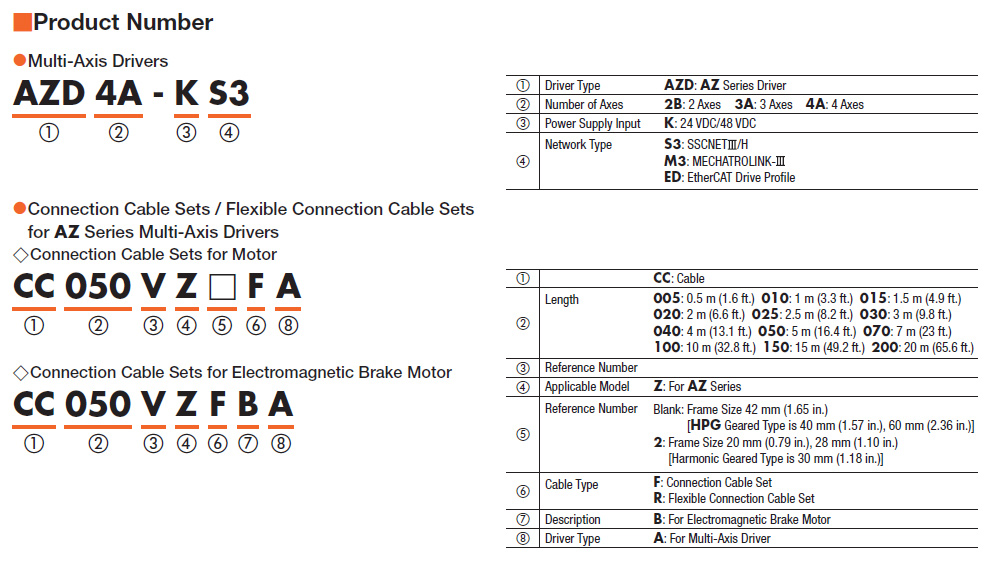

Part Number Code

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.