Linear Actuators - Electric Linear Slides, Electric Linear Cylinders, Rack and Pinion Actuators

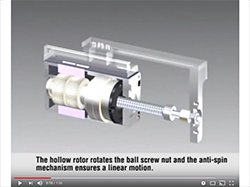

Motors offer excellent controllability and are therefore used as the drive sources of various automated equipment. In many cases a stepper motor is combined with various mechanical components such as a ball screw, belt and pulley, and rack and pinion to convert the motor rotation to a different type of motion needed to drive the equipment such as a linear actuator. Oriental Motor has various linear actuators consisting of a stepper motor assembled with the necessary mechanical components to meet the various needs of automated equipment.

Learn more about our αSTEP family of products

Equipped with a motor offering excellent controllability, our linear actuators offer the following advantages over hydraulic and pneumatic actuators:

- The actuator is very stable when operated, even at low speeds. It also offers smooth acceleration and deceleration operation.

- Motions can be programmed with multiple stopping points.

- With a linear actuator using a stepper motor, adjustment of position and speed can be performed easily using data. Setup change is also simple, as you need to do is change the data.

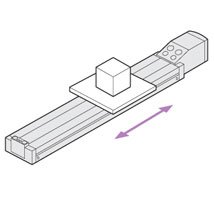

Linear Slides / Linear Actuators

Linear Slides / Linear Actuators

- Quick positioning

- Large transportable mass

- Straight or Reversed Motor type

- X-Axis or Y-Axis Table

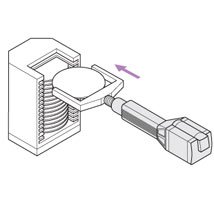

Linear Cylinders / Linear Actuators

Linear Cylinders / Linear Actuators

- Large transportable mass

- Straight or Reversed Motor type

- Guide or No Guide types

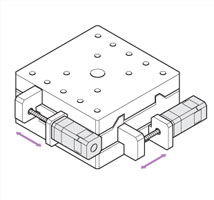

Compact Electric Cylinders

Compact Electric Actuators

- Table or Rod types

- Ground or Rolled ball screw

- Significantly fewer parts

- Reduced assembly time

Stepper Motor Linear Actuator Attachment

Stepper Motor Linear Actuator Attachment

- Linear motion mechanism with a leadscrew and a resin nut

- Easy installation without the need of coupling to an Oriental Motor stepper motor

- For the 42 mm frame size, thrust and self locking force are both a max. 100 N

Electric Gripper / Robotic Gripper

Electric Gripper / Robotic Gripper

- Provides Delicate, Human-like Grip for Robotic Applications

- 2-Finger or 3-Finger Types

- Built-In battery-free absolute sensor, for constant monitoring of motor position information without an external sensor

- High reliability with closed loop control

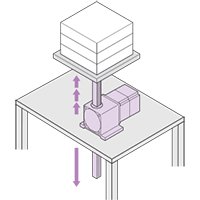

Rack and Pinion Linear Actuators

Rack and Pinion Linear Actuators

- Horizontal or Vertical movement

- High-Speed or High-Transportable-Mass Type

- Electromagnetic Brake options

- Stepper Motor or Speed Control Motor options

THK Linear Slides / Linear Actuators

THK Linear Slides / Linear Actuators

- High Rigidity, Compact and Space Saving

- Normal, High Accuracy and Precision types

- Motor, Coupling, Flange kits (sold separately)

Advantages of Using Linear Actuators, Linear Slides and Linear Cylinders

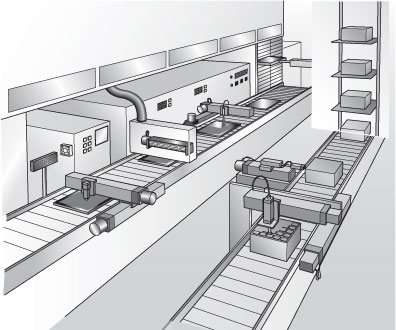

When automated equipment is designed, various factors must be taken into consideration including the production line layout, installation environment, ease of maintenance, configuration of electrical wiring and control system, and so on. This means many man-hours are needed to select the motor and other mechanical components and create a parts list, drawings, operating manuals and the like. Use of linear and rotary actuators can reduce this time and offers additional benefits.

Higher Design Efficiency

The primary feature of automated equipment is its ability to implement a series of basic operations such as "transfer", "push" and "rotate." In other words, you can design automated equipment by selecting and combining linear and rotary actuators capable of performing these basic operations. Since all you need is to select an actuator, you can save the time and effort.

Shorter Production Time and Higher Quality

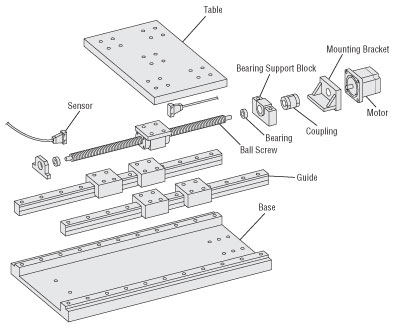

When building equipment in-house by assembling a motor and mechanical components (see illustration), the quality of assembly affects the traveling resistance and position accuracy, therefore ultimately adjustments will be needed to achieve the expected operating performance. On the other hand, our linear and rotary actuators are complete products guaranteed to provide the specified operating performance, so use of linear and rotary actuators reduces adjustment work and ensures uniform quality.

Oriental Motor offers various linear and rotary actuators to help you improve your design productivity.

Electric Linear Slides

The motor is integrated with a linear motion mechanism which makes this actuator ideal for transferring loads.

Electric Linear Cylinders

The motor is integrated with a linear motion mechanism, which makes this actuator ideal for pushing and pulling loads.

Compact Electric Cylinder

A stepper motor is integrated with a ball screw. An ideal actuator for pushing and pulling small loads or fine-tuning applications.

Rack and Pinion Linear Actuators

A rack and pinion mechanism combined with a motor to provide horizontal or vertical linear motion.

αSTEP Hybrid Control System

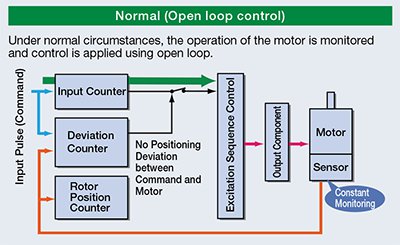

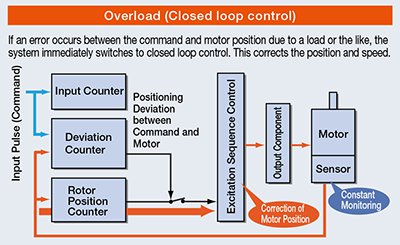

αSTEP products are stepper motor based hybrid motors with a unique hybrid control system combining the benefits of "open loop control" and "closed loop control".

The position of the motor is always monitored, and then the driver automatically switches between 2 types of control depending on the situation.

Normally Operates in Open Loop Control for the Same Ease of Use as a Stepper Motor

High Response

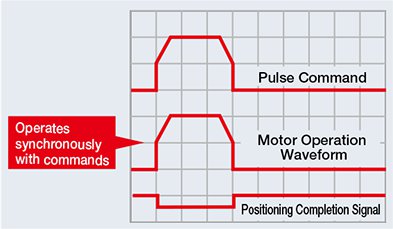

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

Holding the Stop Position without Hunting

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

Tuning-Free

Because it is normally operated with open loop control, positioning is still possible without gain adjustment even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Switches to Closed Loop Control during Overload for More Reliable Operation like a Servo Motor

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

It operates synchronously with commands using open loop control during normal conditions. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.