Service Life

The life of our products is an important factor you should consider when determining the maintenance and/or inspection timing of your equipment. This section explains the definition of life for each of our products. Since the life is not a guaranteed value, please use it only as a reference for proper maintenance and inspection.

Service Life of a Motor

The life of Oriental Motor products is an important factor in determining the maintenance and inspection timing of your equipment. This section explains the definition of life for each of our products. Since life is not a guaranteed value, please use it only as a reference for proper maintenance and inspection.

The life of a bearing greatly affects the design life of a motor.

The life of a bearing can be expressed in 2 ways:

- ① Grease life is affected by grease deterioration due to heat

- ② Mechanical life is affected by rolling fatigue

In most cases, the motor life is estimated based on ① the grease life, since the bearing life is more affected by grease deterioration due to heat generation than the load applied to the bearing.

Temperature is the primary determinant of bearing grease life, meaning that grease life is significantly affected by temperature. A simple representation of this is shown in the graph below.

This graph shows that the life of bearing grease is halved with every 15 °C temperature rise in the bearing.

Taking measures to lower the motor temperature is effective for extending the motor's life.

The table below shows the average bearing grease life for each motor as reference.

Products |

Operating Condition |

Estimated Average Life of Bearing Grease [h] |

|---|---|---|

Induction Motors |

Operation

Torque

Load Type

Speed

Ambient Temperature

|

30,000 |

Brushless Motors |

40,000 |

|

Servo Motors |

Surface Temperature of Motor Case

|

50,000 |

Stepper Motors |

- Note that the life of bearing grease is greatly affected by operating conditions, such as method of use and environmental conditions.

AC Motors, Brushless Motors, and Servo Motors

Be sure to keep the surface temperature of the motor case at 90 °C max.

Stepper Motors

Be sure to keep the surface temperature of motor case at 100 °C* max.

Because of the effects of operating ambient temperature and operating duty, the lower the motor surface temperature, the longer the motor life becomes.

On rare occasions such as when the motor is subjected to a large radial load, the mechanical life may become shorter than the grease life.

- *The AZ Series is 80 °C max., and the PKP Series/PK Series with encoder is 85 °C max.

Service Life of a Gearhead

The gearhead life is reached mainly when power can no longer be transmitted because the bearing mechanical life has ended. Therefore, the actual life of a gearhead varies depending on the load, how the load is applied, and the rotation speed used. Oriental Motor defines life under certain conditions as rated life, based on which the life under actual operation is calculated according to load conditions and other factors. The tooth surface of Oriental Motor's gearheads is lubricated by a grease lubrication mechanism. Lubrication is not required.

Rated Life of Parallel Shaft and Right-Angle Shaft Types

The rated life of parallel shaft and right-angle shaft types is determined by the load applied to the bearing by the transmission torque and the load applied to the bearing by the radial and axial loads on the output shaft.

Oriental Motor defines the rated life as the life of a gearhead under the following operating conditions:

Conditions

- Torque : Permissible torque

- Load Type : Uniform load

- Input Rotation Speed : Reference input rotation speed

- Radial Load : Permissible radial load

- Axial Load : Permissible axial load

Table 1: Rated Life Time of Parallel Shaft and Right-Angle Shaft Types

Motor Type |

Series |

Gearhead Type |

Reference Input Rotation Speed |

Rated Life |

|---|---|---|---|---|

AC Motors |

KIIS Series |

Parallel Shaft Gearhead |

1500 |

10000 |

Right-Angle Hollow Shaft Hypoid GV Gearhead |

||||

JH Gearhead, JL Gearhead |

5000 |

|||

BH Series |

Parallel Shaft Gearhead |

5000 |

||

Right-Angle Gearhead |

10000 |

|||

World K Series |

Parallel Shaft Gearhead |

5000 |

||

Right-Angle Gearhead |

||||

TM Series |

Parallel Shaft Gearhead |

10000 |

||

Torque Motors |

Parallel Shaft Gearhead |

5000 |

||

FPW Series |

Parallel Shaft Gearhead |

5000 |

||

AC Speed Control Motors |

US2 Series |

Parallel Shaft Gearhead |

10000 |

|

JH Gearhead, JL Gearhead |

5000 |

|||

US Series |

Parallel Shaft Gearhead |

5000 |

||

Right-Angle Gearhead |

||||

Brushless Motors |

BMU Series |

Parallel Shaft Gearhead |

3000 |

10000 |

Parallel Shaft Gearhead |

5000 |

|||

Hollow Shaft Flat Gearhead |

10000 |

|||

JH Gearhead, JB Gearhead, JV Gearhead |

5000 |

|||

BXII Series |

Parallel Shaft Gearhead |

10000 |

||

Hollow Shaft Flat Gearhead |

||||

BLH Series |

Parallel Shaft Gearhead* |

10000 |

||

CS Geared Type |

||||

Hollow Shaft Flat Gearhead |

||||

αSTEP/ |

AZ Series |

TS Geared Type |

1500 |

10000 |

FC Geared Type |

5000 |

|||

AR Series |

TH Geared Type |

5000 |

||

FC Geared Type |

||||

CRK Series |

TH Geared Type |

5000 |

||

2-Phase PK Series |

SH Geared Type |

5000 |

||

2-Phase PKP Series |

SH Geared Type |

10000 |

||

CS Geared Type |

||||

5-Phase PKP Series |

TS Geared Type |

10000 |

- *15 W has a rated life of 5000 [hours].

Planetary Geared Type Rated Life

The rated life of the planetary geared type is determined by the load applied to the bearing due to the radial or axial load applied to the output shaft.

Oriental Motor defines the rated life as the life of a gearhead under the following operating conditions:

Conditions

- Torque: Permissible torque

- Load Type : Uniform load

- Input Rotation Speed : Reference input rotation speed

- Radial Load : Permissible radial load

- Axial Load : Permissible axial load

- *Value when either radial load or axial load is applied

Table 2: Rated Life Time of Planetary Geared Type

Motor Type |

Series |

Gearhead Type |

Reference input rotation speed |

Rated Life |

|---|---|---|---|---|

αSTEP/ |

AZ Series |

PS Geared Type |

1500 |

20000 |

AR Series |

PS Geared Type |

20000 |

||

PN Geared Type |

||||

Servo Motors |

AZX Series |

PS Geared Type |

3000 |

10000 |

Rated Life of Harmonic Geared Type and HPG Geared Type

The rated life of the harmonic geared type and the HPG geared type is determined by the load applied to the gears and bearings by the transmission torque, and the load applied to the bearings due to the radial and axial load applied to the output shaft.

Oriental Motor defines the rated life as the life of a gearhead under the following operating conditions:

Conditions

- Torque: Permissible torque

- Load Type: Uniform load

- Input Rotation Speed: Reference input rotation speed

- Radial Load: Permissible radial load

- Axial Load: Permissible axial load

- *The HPG geared type represents the value when either radial load or axial load is applied

Table 3: Rated Life Time of Harmonic Geared Type and HPG Geared Type

Motor Type |

Series |

Gearhead Type |

Reference input rotation speed |

Rated Life |

|---|---|---|---|---|

αSTEP/ |

AZ Series |

HPG Geared Type |

1500 |

20000 |

Harmonic Geared Type |

7000 |

|||

Harmonic Geared Type |

10000 |

|||

AR Series |

Harmonic Geared Type |

5000 |

||

RKII Series |

Harmonic Geared Type |

7000 |

||

Harmonic Geared Type |

10000 |

|||

2-Phase PKP Series |

With flat harmonic gearhead |

5000 |

||

With flat harmonic gearhead |

7000 |

Estimating Lifetime

Lifetime under actual conditions of use is calculated based on the rotation speed, load and load type, using the following formula. The calculated lifetime represents the actual driven hours.

- L1

- Rated life time [hours]

Determined by each gearhead type from Table 1~3.

- K1

-

Rotation speed coefficient

The speed coefficient K1 is calculated based on the reference input rotation speed listed in Table 1~3 and the actual input rotation speed.K1=Reference input rotation speedActual Input Rotation Speed

- K2

-

Load factor

The load factor K2 is calculated based on the actual operating torque and the permissible torque for each gearhead.K2=Operating TorquePermissible torque The average torque may be considered operating torque if the gearhead is subject to load while starting and stopping only, such as when driving an inertial load. Permissible torque represents the specification values listed in the product catalog.

- f

- Load-Type Coefficient f

The load-type coefficient f is determined based on load type, using the following drive examples as a reference:

Load Type |

Example |

Load-Type Coefficient f |

|---|---|---|

Uniform Load |

|

1.0 |

Slight Impact |

|

1.5 |

Medium Impact |

|

2.0 |

Note

Regarding the Effects of Radial Load and Axial Load

- The above estimated lifetime is calculated according to the radial load and axial load, which are in proportion to a given load factor. For example, if the load factor is 50 %, the life is calculated using 50 % radial load and axial load.

- The actual life of a gearhead having a low load factor and a large radial load or axial load will be shorter than the value determined through the previous formula.

How to Obtain the Average Torque

The stepper motor or servo motor is used for intermittent operation of an inertial load, such as driving an index table and arm. In this case, the average torque shall be considered the operating torque, as described below. The load factor for driving an inertial load using an AC motor or brushless motor shall be 1.0.

Driving an Inertia Body Only ①

The graph below shows torque generated when driving only an inertial load over a long operating cycle. Frictional load caused by bearings and other parts during constant speed operation is negligible and therefore omitted.

n1 and n3 represent the average rotation speed in the t1 and t3 area.

In the above example:

Driving an Inertia Body Only ②: Driving an arm or similar object

When driving an arm or similar object, the gearhead may be subjected to load fluctuation as shown in the following graph. For example, such load fluctuation will occur when driving a double-joint arm or moving an arm in the vertical direction. In such an application, the average torque shall be 75 % of the max. acceleration/deceleration torque, as shown in the following formula.

Operating Temperature

An increase in gearhead temperature affects the lubrication of the bearing.

However, the effect of temperature on gearhead life varies according to the condition of the load applied to the gearhead bearings, frame size and many other factors. This makes it difficult to include temperature effects in the formula to estimate the lifetime.

The following data shows the temperature effect on the gearhead bearings. The gearhead life is affected when the gear case's surface temperature is 55 °C min.

Note

In some cases, a lifetime of several tens of thousands of hours may be obtained from the calculation under certain conditions. Use the estimated life as a reference only.

The above life estimation is based on the bearing life.

An application in excess of the specification values may adversely affect parts other than the bearings. Use the product within the range of specified values listed in the product catalog.

Service Life of a Circuit Product

The life of each of Oriental Motor's circuit products is determined by the aluminum electrolytic capacitor inside the product. Our circuit products are designed so that their life will be reached after 5 years min. when the product is used continuously under an ambient temperature of 40 °C. (Excluding certain products.)

In addition, an aluminum electrolytic capacitor generally exhibits the characteristics according to the "Arrhenius equation." Specifically, as shown in the figure below, a temperature rise of 10 °C reduces the life of an aluminum electrolytic capacitor to half, while a temperature drop of 10 °C will extend the life to twice as long.

Since the lifetime of a circuit product varies depending on the operating environment and conditions, Oriental Motor recommends that the curve shown in the figure below be used to determine the need for preventive maintenance to keep the product free from failure.

Service Life of a Motorized Linear Slide and Motorized Cylinder

The life of an electric linear slide and electric cylinder is generally affected by the rolling fatigue life of its ball screw, guide and ball bearing. When stress is applied repeatedly to the raceways and the rolling ball, flaking (a phenomenon in which the metal surface turns into small scale-like pieces and separate from the base metal) occurs due to material rolling fatigue.

The rolling fatigue life refers to the time until the flaking occurs.

An expected life is calculated for each product based on its maximum ratings (maximum load mass, maximum speed, load moment, etc.) as a reference for calculating the product's life.

Reference for Expected Life Distance in Each Series

Series |

Lead 12 mm |

Lead 6 mm |

Lead 3 mm |

|---|---|---|---|

EAS Series |

5000 km |

3000 km |

1500 km |

EZS Series |

5000 km |

3000 km |

− |

EAC Series |

5000 km |

3000 km |

1500 km |

| Series | Lead 30 mm | Lead 20 mm |

|---|---|---|

| EZSH Series | 20000 km | 20000 km |

The expected life distance of the guide part of electric linear slides/electric cylinders (equipped with shaft guide) is designed with reference to the life of each series.

However, under conditions where the load moment formula is greater than 1, the expected life distance will be less than the expected value.

Use the formula below to approximate the expected life distance.

For calculation of the load moment, refer to "Calculation of Load Moment."

- *The expected life distance varies depending on the product. Refer to the table above for details.

Service Life of Compact Electric Actuators

Actuator |

Lead |

Distance |

DRS20 |

1 mm |

200 km |

DRS28 |

1 mm |

200 km |

2.5 mm |

1250 km |

|

DRS42 |

2 mm |

400 km |

8 mm |

1600 km |

|

DRS60 |

4 mm |

800 km |

Service Life of Linear Actuator Attachments

Attachment |

Lead |

Distance |

LA4 |

2 mm |

50 km |

12 mm |

300 km |

Service Life of Rack and Pinion Gearhead

The life of the rack-and-pinion mechanism is the condition where power cannot be transmitted due to the mechanical life of the gear.

Oriental Motor defines rated life as the life of the product under the most severe conditions of maximum transportable mass and speed, according to our catalog specifications value. Therefore, the actual life varies depending on the size of the load, how the load is applied, and the operating speed.

Rated Life

- Rack-and-Pinion Mechanism: 2,000 hours

Service Life of Electric Grippers

Oriental Motor’s electric gripper (EH4) has been tested for 20 million grasps at the maximum gripping force and has been confirmed to work normally.

The figure of 20 million grasps is only a reference value, and is not a guaranteed value. Actual life varies depending on operation conditions.

Service Life of Hollow Rotary Actuators

We have confirmed via testing that our hollow rotary actuators (DGM) operate properly for 10 million back-and-forth rotations.

The figure of 10 million back-and-forth rotations is only a reference value, and is not a guaranteed value. Actual life varies depending on the ambient temperature and operating conditions.

Actual Test Conditions

- Back-and-forth operation at 180˚ when an inertial load is installed

- Number of back-and-forth rotations: 10 million

- Operating Torque: Maximum permissible torque value (safety factor times 1)

- *The safety factor of the operating torque must be 1.5~2 times greater (reference values).

The safety factor (times 1) is used for Oriental Motor's actual test.

Service Life of a Cooling Fan

Cooling fan life represents the condition in which the fan's capability to generate air flow has deteriorated due to continuous operation over a certain period of time, or the fan can no longer be used due to significant noise.

Service Life of Cooling Fans

- ① Rotation life - Life as defined by certain value deterioration in fan rotation speed

- ② Sound life - Life as defined by certain increase in noise

The rotation life in ① can be easily measured, and the factors involved can be clearly specified numerically. This is usually what is meant when referring to life.

Sound life in ②, on the other hand, is defined by an increase in decibel level, while determining exactly what amount of increase marks the end of sound life is determined by the user's judgment. Moreover, fans can still meet the operating conditions even after reaching the predetermined increase level in noise. In short, there are generally no specific references or lifetime.

Oriental Motor defines the cooling fan life by ① rotation life; a fan is judged to have reached the end of its life when speed drops to 70 % of the rated speed.

Cooling Fan Bearing Life

Cooling fans use a ball bearing. The following explanation applies to the life of a ball bearing. Since the load applied to cooling fan's bearings is negligible, life of a cooling fan is determined by the deterioration of the grease in the bearings.

Since the cooling fan's operating and starting torques are already smaller than those of a power motor, lack of lubrication due to grease deterioration will cause the starting and dynamic torques of the bearing to increase excessively, which may prevent the fan from starting. Deterioration of grease also increases the noise generated by the bearings, further affecting the life of a cooling fan.

Grease life is given by the following formula:

- K1, K2, K3, K4

- Constant determined by grease

- Nmax

- Maximum number of rotations allowed by grease lubrication

- Nmax

- Maximum number of rotations allowed by grease lubrication

As indicated by the above formula, Nmax is predetermined by the bearings, so grease life depends on the temperature and rotation speed of bearings. However, Oriental Motor's products are designed so that the bearing life is only minimally affected by their rotation speed. n N maxnNmax is a constant value, which means that the grease life is determined by temperature.

Estimated Life

This is the life estimated by the grease life formula for bearings (ball bearings).

Estimated Life Characteristics

The figure below gives the estimated life characteristics of a cooling fan. (Example: compact AC input cooling fan MU1238A type)

This graph estimates the life of the bearing using the formula for bearing grease life based on actual measurements of temperature rise of the cooling fan bearings at the rated voltage.

Expected Life

It indicates that at least 90 % of the fans will satisfy the following criteria when the acceleration test is performed at the operating ambient temperature's upper limit value.

Criteria

- Rotation Speed (at rated voltage): 70 % min. of rated value

- Input Current (at rated voltage): 130 % max. of rated value

Relationship Between the Duration of Use and Failure Rate

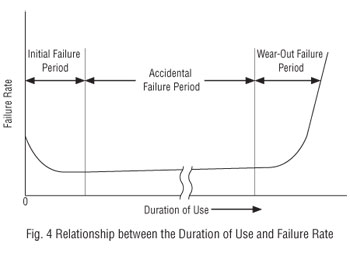

Generally, failure rate of parts relative to the duration of use fits the pattern of three states: initial failure, accidental failure or wear-out failure, as shown in Fig. 4.

The risks of initial failures are eliminated in the inspection process of the production line, but accidental failures are sudden failures that occur randomly and unexpectedly during the durable life of the product before wear progresses. Therefore, it is difficult to provide engineering protection against accidental failures, and the only measure available presently is to predict occurrences based on statistical data.

Wear-out failures occur at the end of the product's durable life as a result of deterioration and wear. The rate of wear-out failure increases dramatically after a certain period. Replacing certain parts at this point will provide an effective means for preventive maintenance.

(Excerpt from "Recommendation for Periodic Inspection of General Inverters" by the Japan Electrical Manufacturers' Association).

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)