Electric Linear Slides Glossary of Terms

Below you will find an overview of the terms most commonly associated with our electric linear slides product lines.

Linear Slide Terms

Acceleration/Deceleration Rate

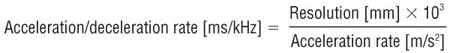

Acceleration rate indicates the change in speed per unit time. Acceleration rate is expressed in "m/s2" when the international system of units (SI) is followed, or in the gravitational unit of "G" based on gravitational acceleration rate. The conversion formula is as follows:

![]()

With Oriental Motor's controllers (except for linear motion controllers), acceleration rate is referred to as "acceleration/ deceleration rate." The unit of acceleration/deceleration rate is ms/kHz. The conversion formula is as follows:

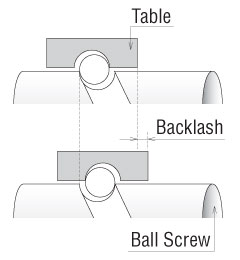

Backlash

A play along the ball within the raceways of the ball screw and screw nut.

Ball Retainer® (Manufactured by THK)

The Ball Retainer® holds individual balls in a manner preventing contact between adjacent balls and thereby allowing smooth rotation of balls. The LM Guide® adopting Ball Retainer® is structured so that the balls move along a circular path while being held by Ball Retainer®.

This structure provides the following benefits:

• The balls do not make contact with each other and thus grease lasts longer, resulting in a longer life and maintenance-free period. Since grease does not splash much, less dust is produced.

• The balls move smoothly and generate less noise without clashing with each other.

• The balls do not make contact with each other and thus less heat is generated, which makes this structure ideally suited for high-speed operation.

• Ball Retainer and LM Guide are registered trademarks of THK Co., Ltd.

Grease

The class of lubricants applied to smooth the movement of guides and moving parts of the ball screw. Grease forms an oil film on metal surface to reduce wear and friction, thereby prolonging the life and preventing rust. Linear slides require periodic maintenance of grease according to their use conditions.

Life

The life of a linear slide is generally affected by the rolling fatigue life of its ball screw or linear guide. When stress is applied repeatedly to the raceways and rolling elements of the ball, flaking (a phenomenon in which the metal surface turns into small scale-like pieces to separate from the base metal) occurs due to material fatigue caused by rolling fatigue. The rolling fatigue life refers to the time until the flaking occurs.

Since the life of each linear guide or ball screw is varied, a rated life is calculated for each product based on its maximum ratings (maximum transportable mass, maximum speed, etc.) as a reference for calculating the product's life. The life values specified for our products are not guaranteed. A reference traveling life of the EZSII Series is 5000 km (3000 km for EZS□E).

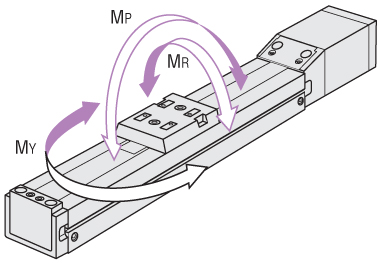

Load Moment

When the load acting upon the table extends beyond the table in the longitudinal, lateral or vertical direction, the linear slide receives a torsional force. This torsional force is referred to as "load moment." Moment applies in the three directions of pitching (MP), yawing (MY) and rolling (MR), as shown below. In a condition where moment is not applied in two of these three directions, the permissible moment applied only in one direction is defined as the maximum value of moment. Permissible moments in respective directions are specified for each product.

Long-Term Maintenance-Free

Here, "maintenance" specifically refers to maintenance of grease. The maintenance interval can be extended considerably through the use of a lubrication system QZ™.

Lost Motion

The difference between positions achieved by repeated positioning operations to the same positioning point performed in the positive and negative directions.

Lubrication System QZ™ (Manufactured by THK)

A lubrication system that supplies an appropriate amount of lubricating oil to the raceways of the ball screw. An oil film is maintained between the rolling element and raceways, which extends the maintenance interval considerably.

Maximum Load Moment (Pitching direction, yawing direction, rolling direction)

The life of each linear slide is defined as a corresponding travel distance, which is affected by the moment that can be tolerated by the table. The maximum load moment indicates the maximum value of moment with which the linear slide can reach its specified life.

Mounting Reference Surface

Reference surfaces used for mounting are provided on the body of the linear slide. These reference surfaces are used to install the linear slide in the same position after removal for maintenance, etc.

Operation Duty

The ratio of the time spent by the linear slide to perform one operation to the time during which it is stopped (= operating ratio of the motor). Oriental Motor's linear slides should be used at an operation duty of not more than 50%. If the operation duty exceeds 50%, the motor surface temperature may rise to 100˚C or above and the motor life will be reduced as a result. If the ambient temperature remains at or below the maximum allowable ambient temperature specified for each product +40˚C, the motor surface temperature should not exceed 100˚C as long as the operation duty remains 50% or below. If the operation duty will exceed 50%, take appropriate measures to keep the motor surface temperature under 100˚C.

Positioning Time Coefficient

Multiplying the positioning time coefficient by the positioning time needed when the linear slide is operated at the maximum ratings provides the positioning time required at the maximum speed corresponding to the applicable stroke. The longer the stroke, the lower the maximum drivable speed becomes in order to prevent the ball screw from reaching a critical speed. (For the positioning time coefficient of each product, refer to "Positioning distance – positioning time.")

Repetitive Positioning Accuracy

A value indicating the amount of error that generates when positioning is performed repeatedly to the same position in the same direction.