Electric Linear Cylinders Glossary of Terms

Below you will find an overview of the terms most commonly associated with our electric linear cylinder product lines.

Linear Cylinder Terms

Acceleration/Deceleration Rate

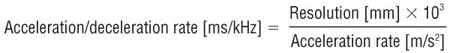

Acceleration rate indicates the change in speed per unit time. Acceleration rate is expressed in "m/s2" when the international system of units (SI) is followed, or in the gravitational unit of "G" based on gravitational acceleration rate. The conversion formula is as follows:

![]()

With Orientalmotor's controllers (except for linear motion controllers), acceleration rate is referred to as "acceleration/ deceleration rate." The unit of acceleration/deceleration rate is ms/kHz. The conversion formula is as follows:

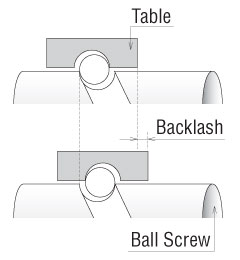

Backlash

A play along the ball within the raceways of the ball screw and screw nut.

Life

The life of a cylinder is generally affected by the rolling fatigue life of its ball screw etc. When stress is applied repeatedly to the raceways and rolling elements of the ball, flaking (a phenomenon in which the metal surface turns into small scale-like pieces to separate from the base metal) occurs due to material fatigue caused by rolling fatigue.

The rolling fatigue life refers to the time until the flaking occurs. Since the life of each ball screw is varied, a rated life is calculated for each product based on its maximum ratings (maximum transportable mass, maximum speed, etc.) as a reference for calculating the product's life.

Lost Motion

The difference between positions achieved by repeated positioning operations to the same positioning point performed in the positive and negative directions.

Operation Duty

The ratio of the time spent by the cylinder to perform one operation to the time during which it is stopped (= operating ratio of the motor). Oriental Motor's cylinders should be used at an operation duty of not more than 50%. If the operation duty exceeds 50%, the motor surface temperature may rise to 100˚C or above and the motor life will be reduced as a result. If the ambient temperature remains at or below the maximum allowable ambient temperature specified for each product +40˚C, the motor surface temperature should not exceed 100˚C as long as the operation duty remains 50% or below. If the operation duty will exceed 50%, take appropriate measures to keep the motor surface temperature under 100˚C.

Overhung Load

Overhung load is the load applied in a direction perpendicular to the output shaft (rod) of the cylinder.

Repetitive Positioning Accuracy

A value indicating the amount of error that generates when positioning is performed repeatedly to the same position in the same direction.