CVD 2-Phase Bipolar Stepper Motor Drivers

CVD 2-Phase Bipolar Stepper Motor Drivers

The CVD 2-phase stepper motors driver offers superior performance and value and is ideal for OEM or single axis machines. The CVD series stepper motor drivers offer:

- Lowest Vibration and Noise with advanced Microstepping control

- Pulse Input, RS-485 Communications or Multi-Axis Type

- Significantly improves positional accuracy when microstepping

- Highest torque with Bipolar configuration (4 lead wire)

- Small, thin microstepping drive with space saving FETs

- Selectable step angle and microstepping filter control

- 2 mounting types and connector configuration

- Various mounting types and connector configurations

- Alarms

- 24 VDC Input / 0.5A to 4.5A

Wide Product Line of Compact Microstepper Drivers to Suit Any Application

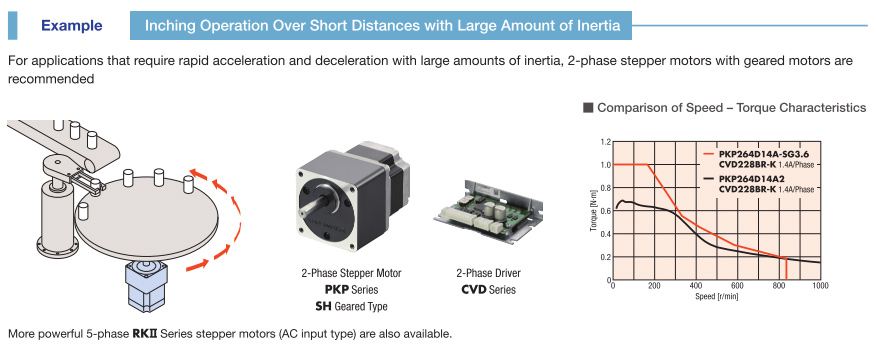

The CVD Series is a compact line of stepper motor drivers capable of handling a wide variety of applications. When used with the PKP Series Stepper Motors, the CVD Series offer the lowest vibration and noise with advanced microstepping control and the highest torque output.

Features of the CVD Series

The CVD Series drivers developed exclusively for the PKP Series stepper motors enables increased performance and functionality.

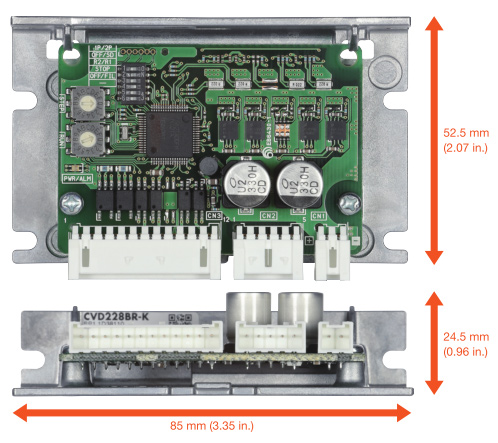

Industry's Top Compact, High Performance Driver

These compact and lightweight drivers contribute to saving space. The 2-phase and 5-phase drivers are identical in size, installation and I/O connectors. This allows for the selection and evaluation of 2-phase or 5-phase drivers based on the required specifications.

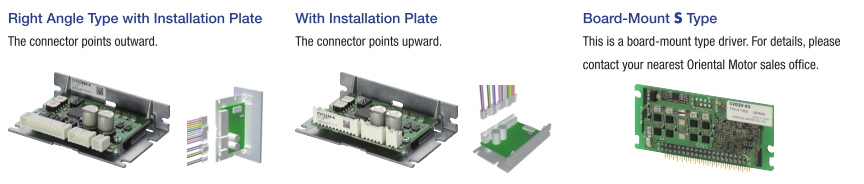

Select Drivers by Mounting Method

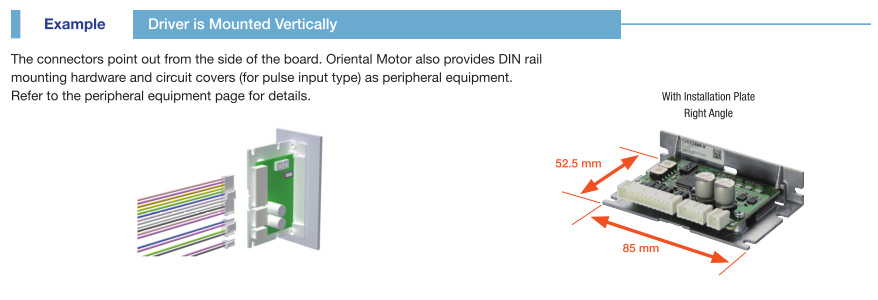

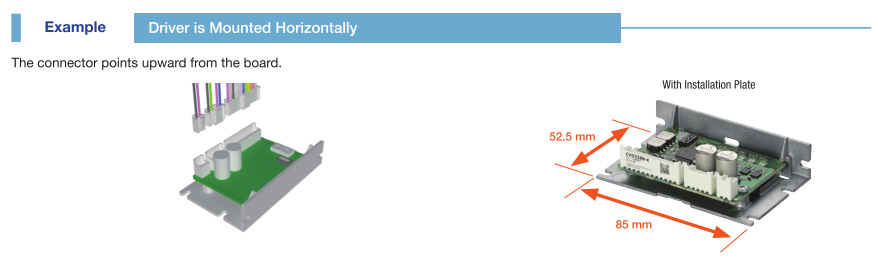

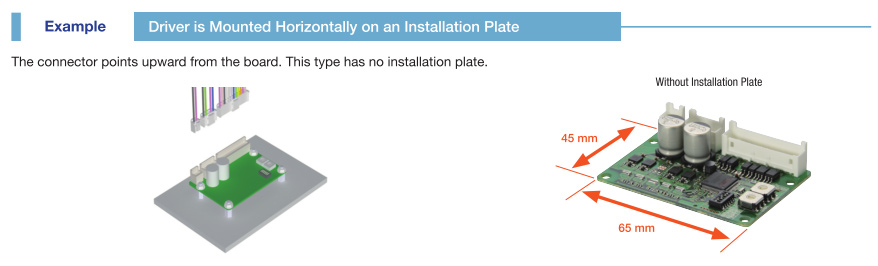

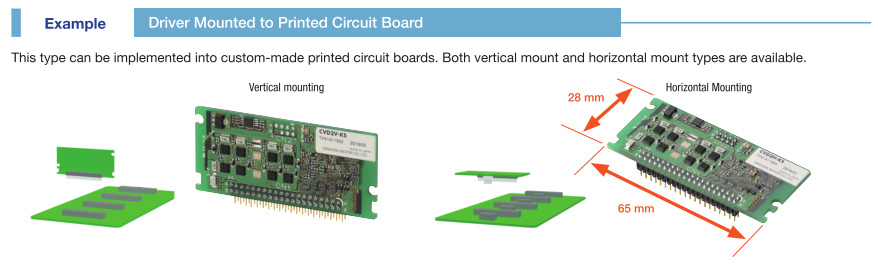

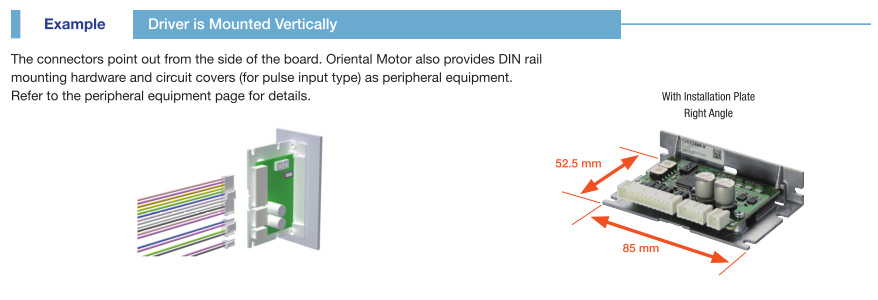

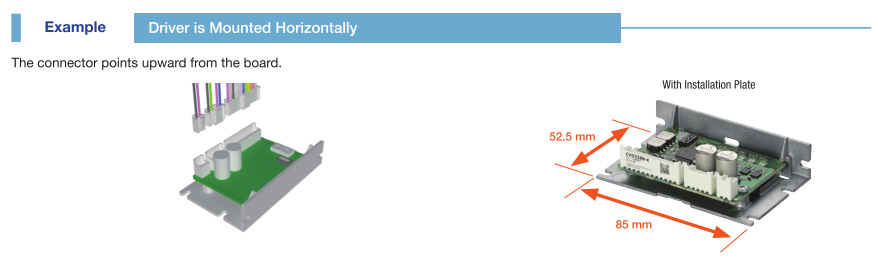

Drivers with different shapes and connector locations are available to match the mounting method.

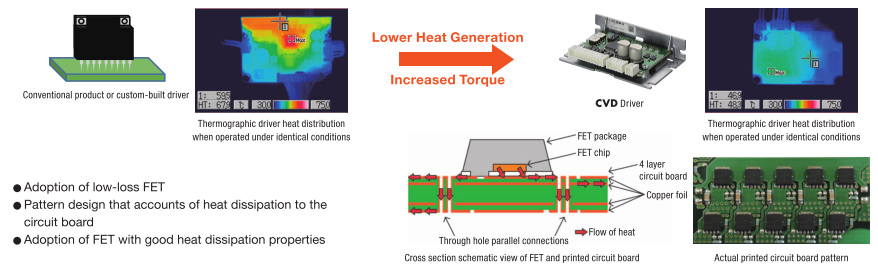

High-Efficiency Design

The CVD Series provides increased torque by increasing the output current compared to conventional products. In order to allow the increase of output current, the design incorporates measures to reduce the amount of heat generated.

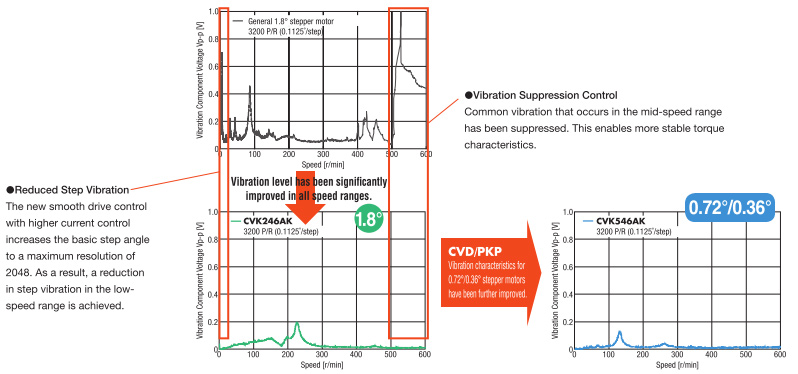

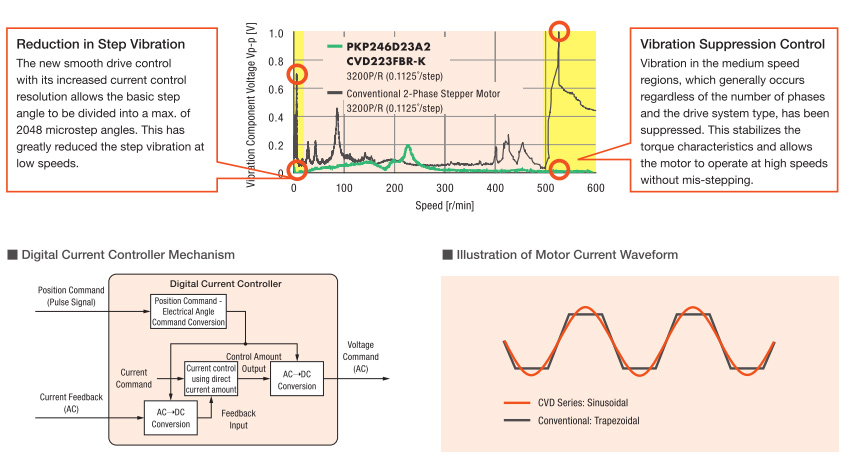

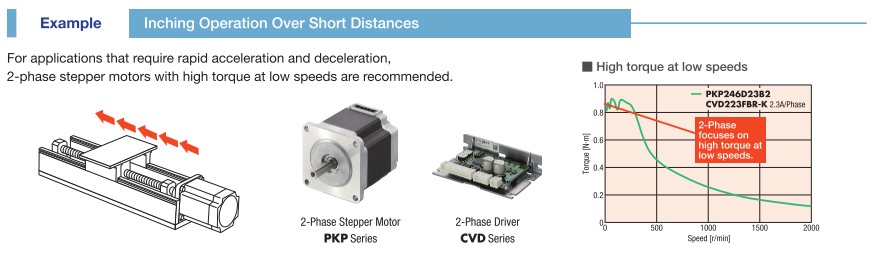

Low Vibration with Full-Time Microstepping

Low vibration and noise reduction have been achieved across all speed ranges by significantly improving the vibration level with the use of a fully digital-controlled full-time microstep driver. The CVD 5 phase driver and motor has further improved vibration characteristic.

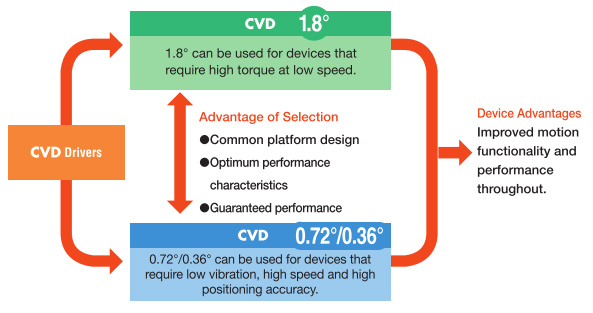

There's a Wide Choice with 1.8° and 0.72°/0.36° Stepper Motors

The size, installation and I/O connectors for the CVD drivers and 1.8° or 0.72°/0.36° motors are the same. Because of this, it is easy to evaluate and select the proper package for the requirement.

Low Vibration Achieved by Full-Time Microstep Drive

The CVD Series is a fully digital control driver. Currents are controlled digitally and calculated by a high-performance CPU. The waveform of the current for each phase is changed from the conventional trapezoidal to sinusoidal, which allows for micro-step driving in all speed regions, and has reduced vibration even more.

A Motor that Matches the Desired Specifications can be Selected from a Wide Range of Speed and Torque Variations

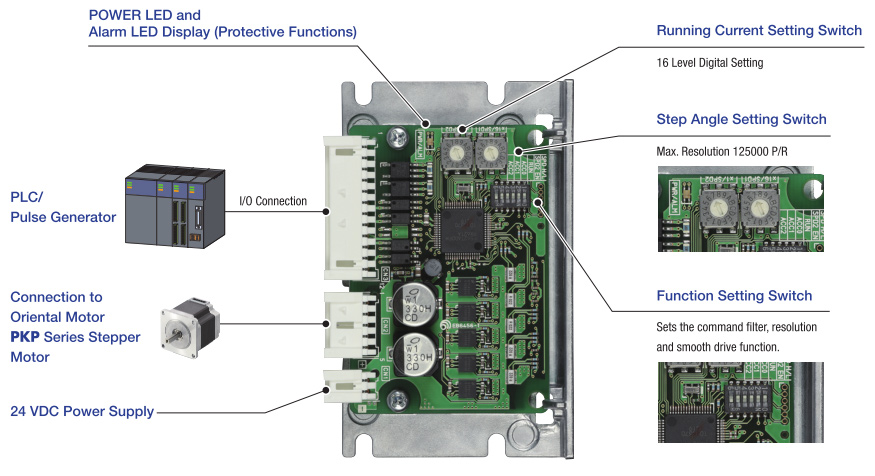

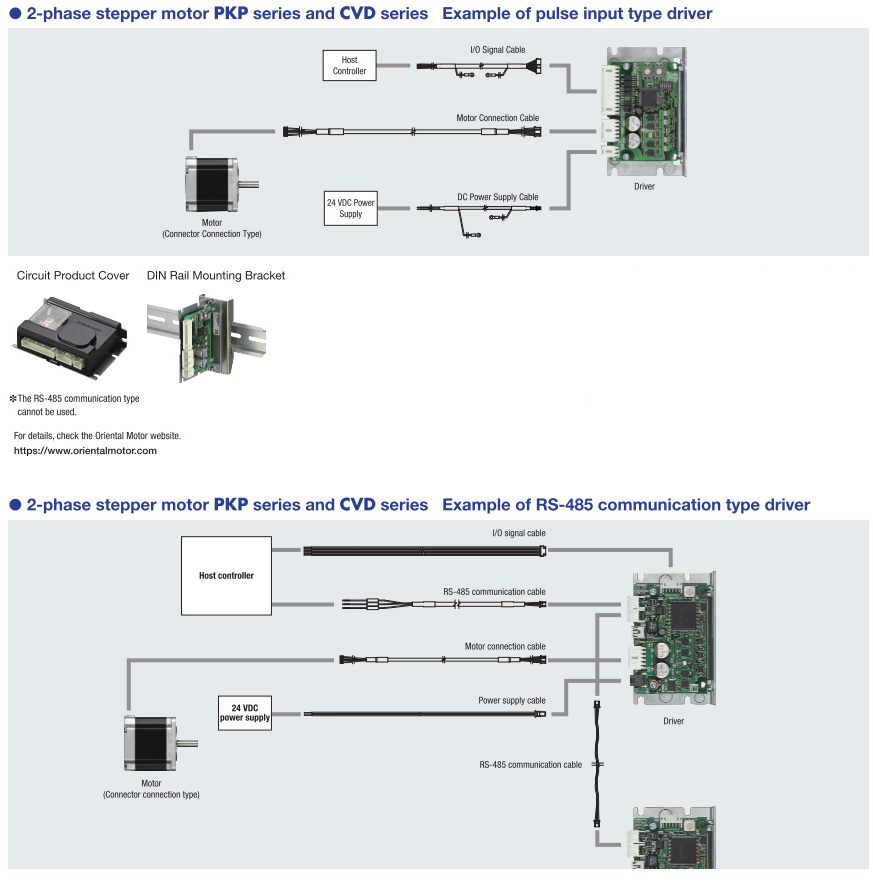

Pulse Input Type Driver

This driver meets the needs for easy synchronized operation with pulse input type drivers.

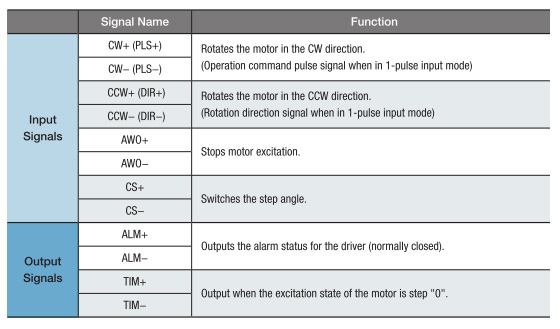

I/O Signals

Mounting Options

Different driver shapes and connection methods are available to meet a wide range of mounting locations.

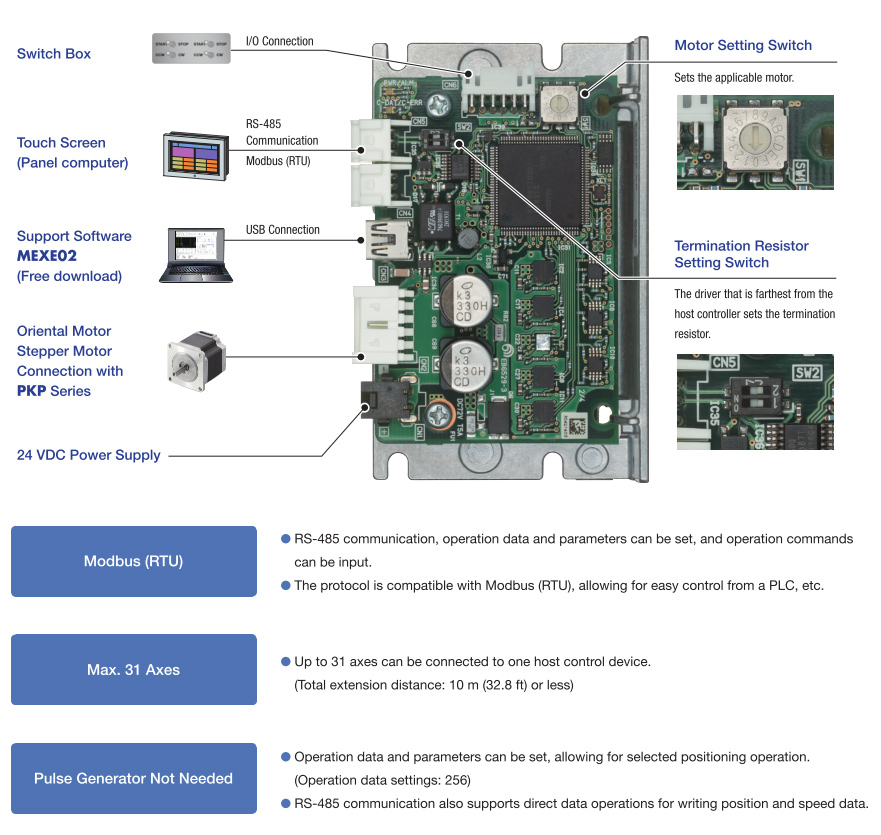

RS-485 Communication Type

Movement with Modbus (RTU) control? Simple data setting with touch screen? These drivers meet those needs.

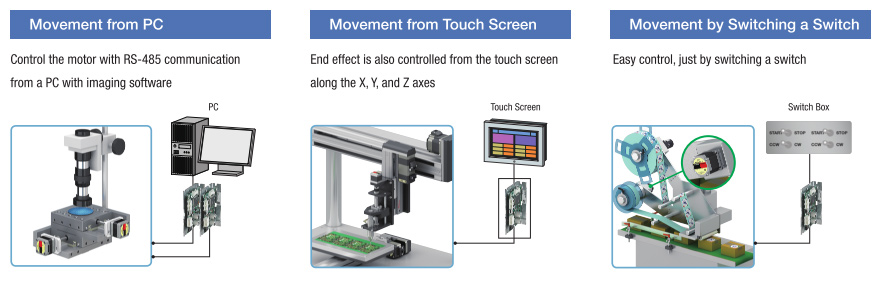

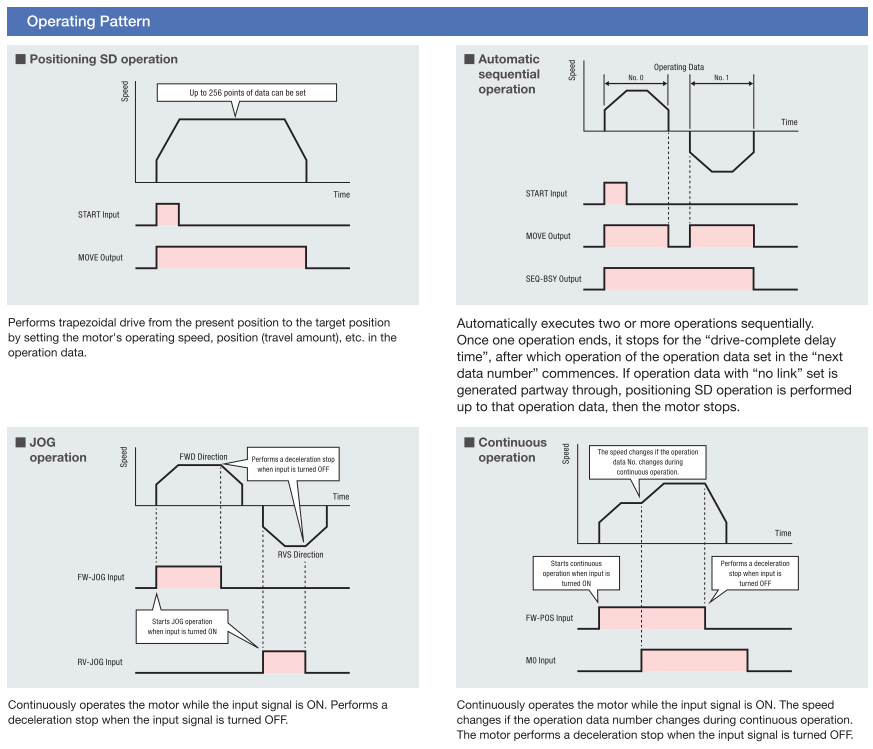

Movement Examples

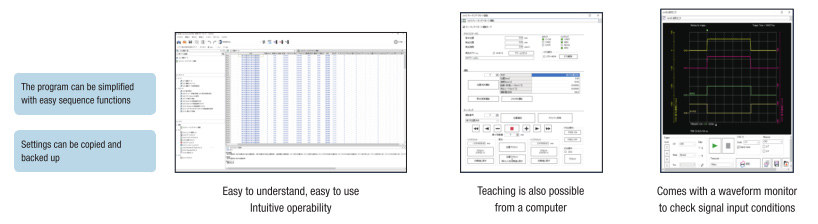

Simple Editing and Setting Operation Data and Parameters

Support Software MEXE02

Basic settings, such as operation data editing and parameter settings, can be easily made from a computer. Sequence control is also possible, making simple system configuration possible without a host sequence.

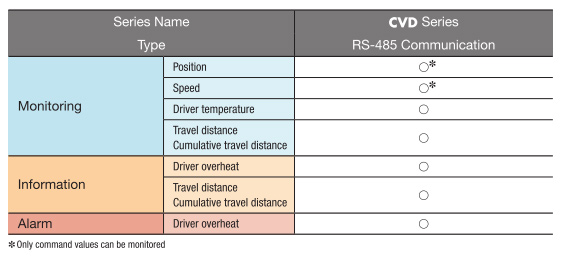

Contributes to Visualization

Comes with a monitoring function that contributes to visualization.

Pulse Generator not Needed

The RS-485 communication type can set operation data in the driver, allowing for operation data to be selected and executed from a host. Operation data can also be linked.

Mounting Options

Different driver shapes and connection methods are available to meet a wide range of mounting locations.

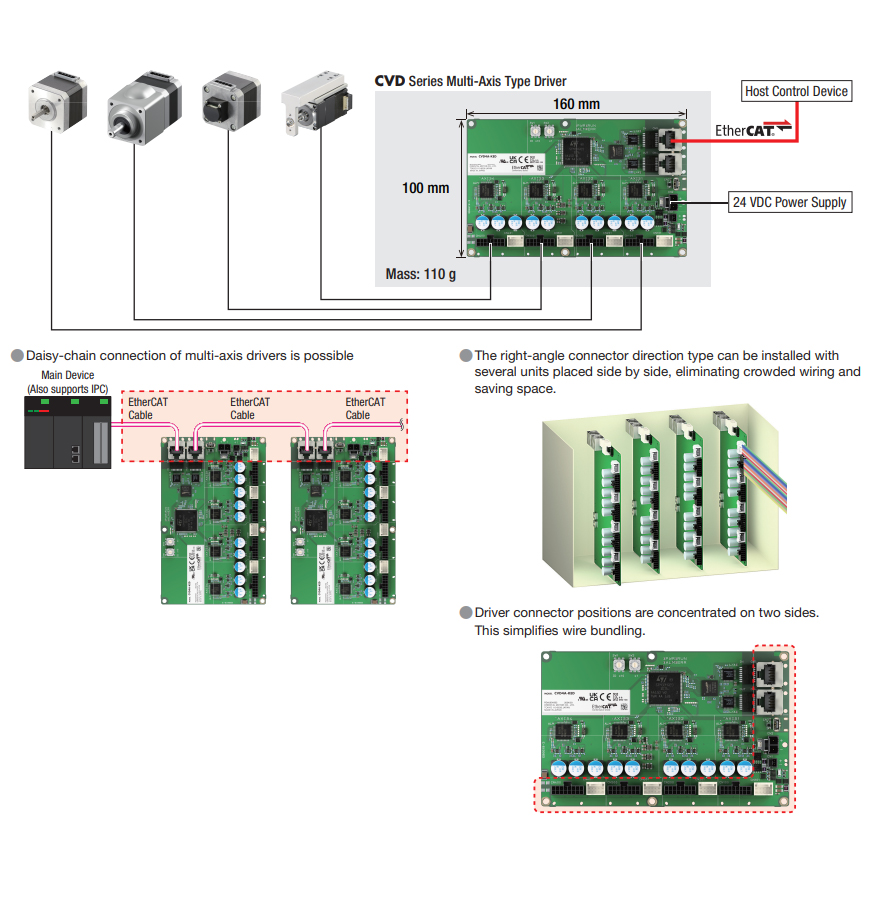

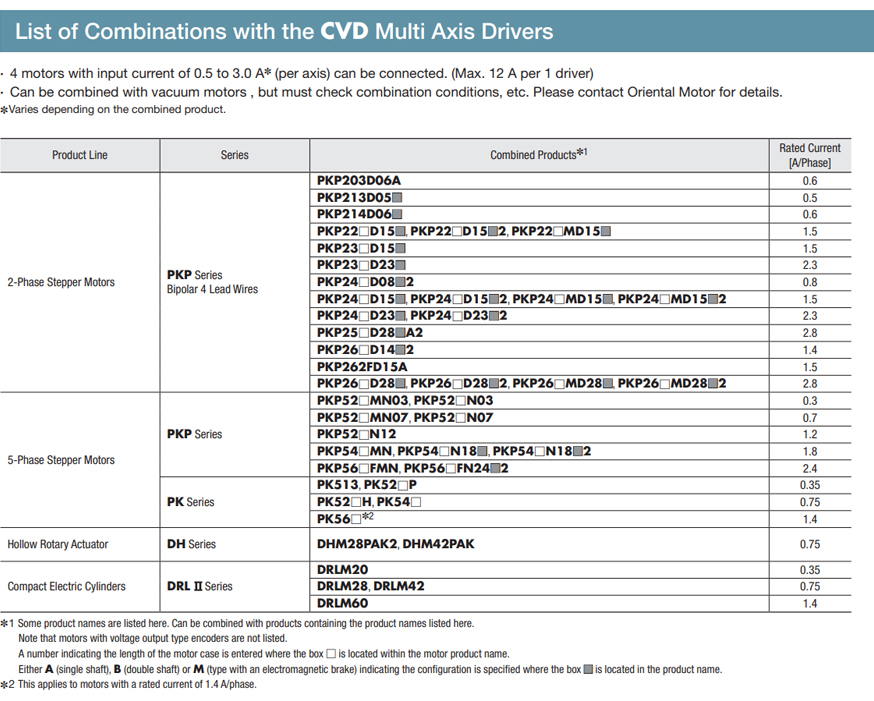

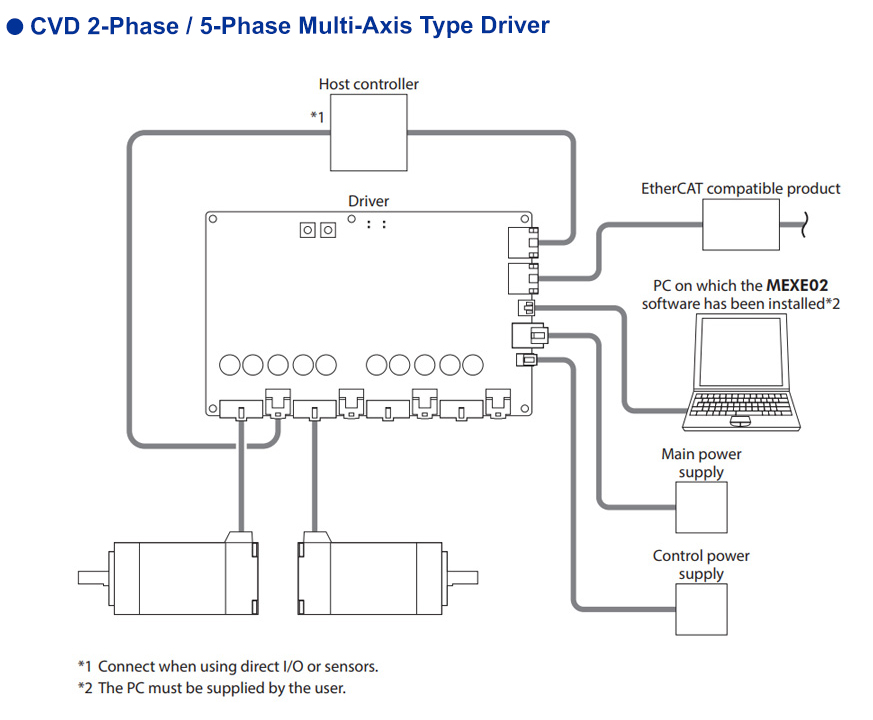

EtherCAT Compatible/4-Axis Control Reduces Wiring and Saves Space

- I/O signals are consolidated into a single EtherCAT communication cable. Wiring for communication, power supply, etc. for 4-axis are integrated into a single driver

- Reduces work hours for wiring and decreases problems from mis-wiring

- Integrated management of device information including motor information by using an EtherCAT master

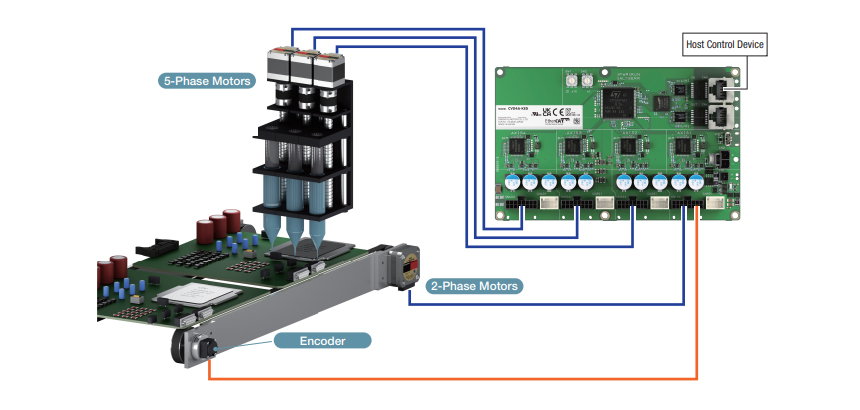

Combined Use of 2-Phase/5-Phase Motors and Synchronous Control is Possible Using EtherCAT Communication

- A single driver can control 2-phase/5-phase motors and actuators, which reduces parts inventory and management costs

- Synchronous control is possible while utilizing the different characteristics of 2-phase/5-phase motors via EtherCAT communication

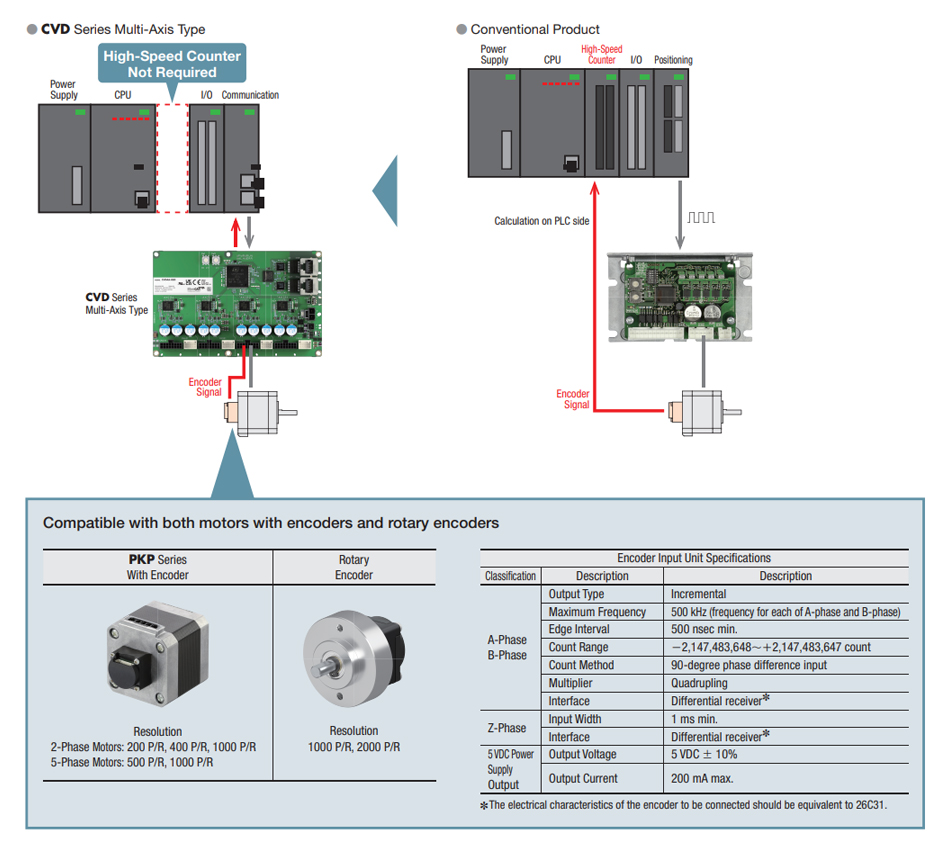

Acquire Encoder Information and Position Deviation Detection

Driver includes a function to acquire encoder information. Position deviation can be detected by the driver and outputs a signal without the need for a host controller. The actual position and speed of the motor can also be monitored on a computer screen by using the support software MEXE02.

- No high-speed counter needed, reducing host controller costs

- Outputs signal to the host controller using EtherCAT communication. Reduces program creation time.

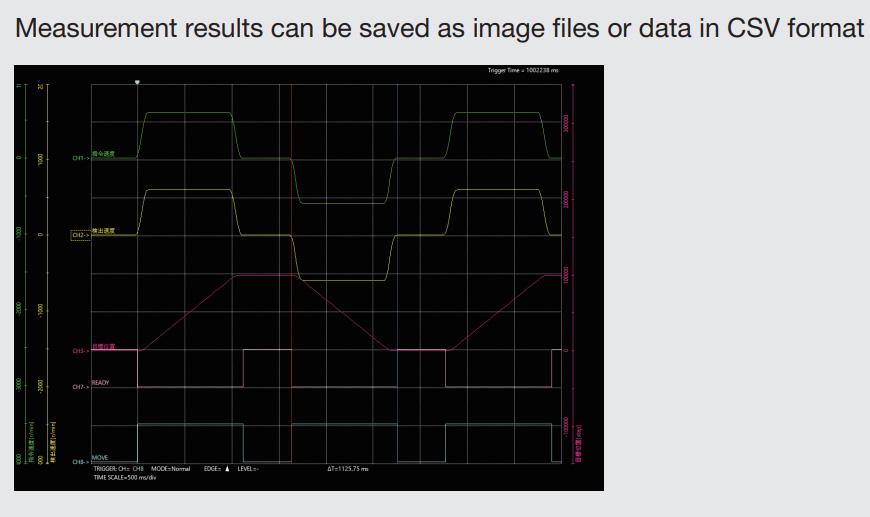

The Encoder Detection Information can be Monitored Using the Support Software MEXE02 (Free)

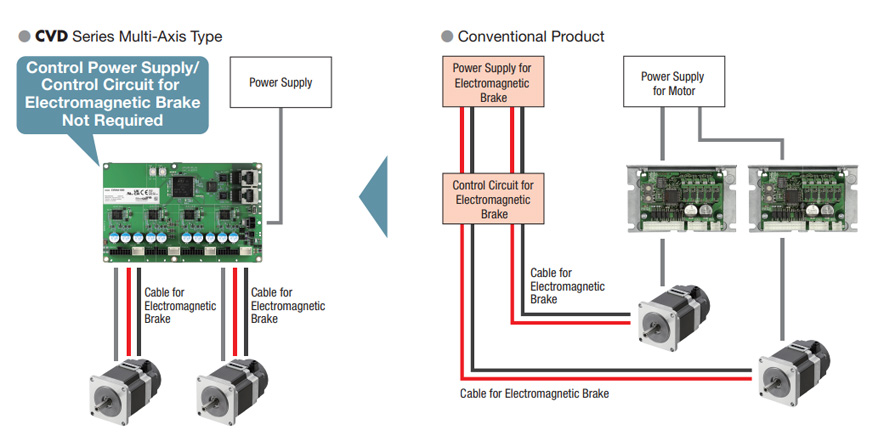

Automatic Control of Electromagnetic Brake and Power Supply

- No electromagnetic brake control circuit is needed, which reduces program creation time

- Reduced wiring work time

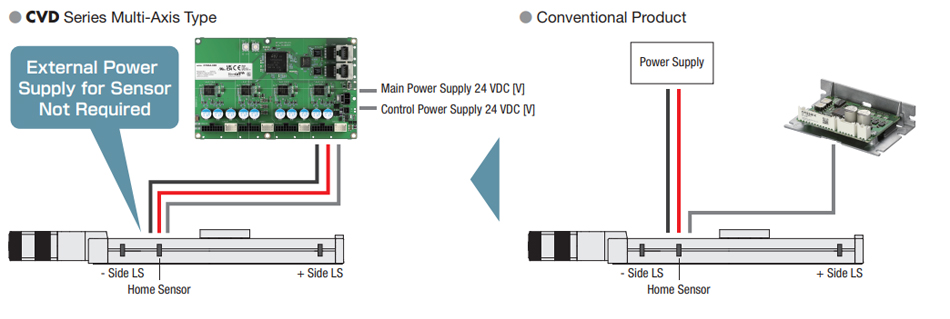

Can Provide Power to Sensors

Other Functions

Alarm Output

- Output of an excessive position deviation alarm allows for detection of motor misstep/stepout (Main circuit overheat alarm, etc. can also be output)

Information

- Output of an excessive position deviation alarm allows for detection of motor misstep/stepout (Main circuit overheat alarm, etc. can also be output)

- Can be monitored using EtherCAT communication

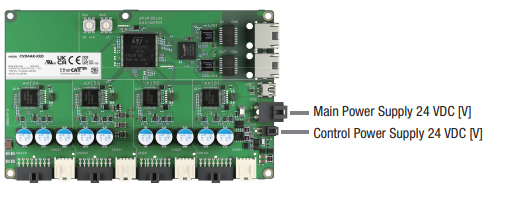

Separation of Main Power and Control Power

- Supports addition of a separate external safety relay to shut off the main power supply

- Can be monitored using EtherCAT communication

- Monitoring, etc. via EtherCAT communication is possible even when the main power supply is shut off

Main Power Supply Inrush Current Suppression Function

- This function protects the circuits in the main power supply unit from inrush currents that occur when the main power supply is turned on.

*PKP Series voltage output type encoder motors are not compatible with this driver

Stepper Motor Driver Lineup

Stepper Motor Drivers |

Driver |

Current |

Motor Types |

Power Supply |

|

|---|---|---|---|---|---|

|

0.13 ~ 0.5 A/Phase |

2-Phase |

24 VDC |

||

0.15 ~ 0.6 A/Phase |

|||||

0.38 ~ 1.5 A/Phase |

|||||

0.58 ~ 2.3 A/Phase |

|||||

0.7 ~ 2.8 A/Phase |

|||||

|

0.13 ~ 0.5 A/Phase |

2-Phase |

24 VDC |

||

0.15 ~ 0.6 A/Phase |

|||||

0.38 ~ 1.5 A/Phase |

|||||

0.58 ~ 2.3 A/Phase |

|||||

0.7 ~ 2.8 A/Phase |

|||||

1.05 ~ 4.2 A/Phase |

|||||

1.125 ~ 4.5 A/Phase |

|||||

|

0.5 ~ 2.8 A |

2-Phase |

24 VDC |

||

|

0.5 ~ 2.8 A/Phase |

2-Phase |

24 VDC |

||

Board Mounting Type |

I/O Setting |

0.5 ~ 2.8 A/Phase |

2-Phase |

24 VDC |

|

SPI Communication |

|||||

Board Mounting Type |

I/O Setting |

0.5 ~ 2.8 A/Phase |

2-Phase |

24 VDC |

|

SPI Communication |

|||||

Multi-Axis Drivers - Board Type

|

0.5 ~ 3.0 A per axis. (Max. 12 A) |

2-Phase 5-Phase |

24 VDC |

||

Multi-Axis Drivers - Board Type Right Angle Connectors

|

0.5 ~ 3.0 A per axis. (Max. 12 A) |

2-Phase 5-Phase |

24 VDC |

||

†Only for use with 1.65 in. (42mm) PKP Series 2-Phase Bipolar Stepper Motors with Flat Connector

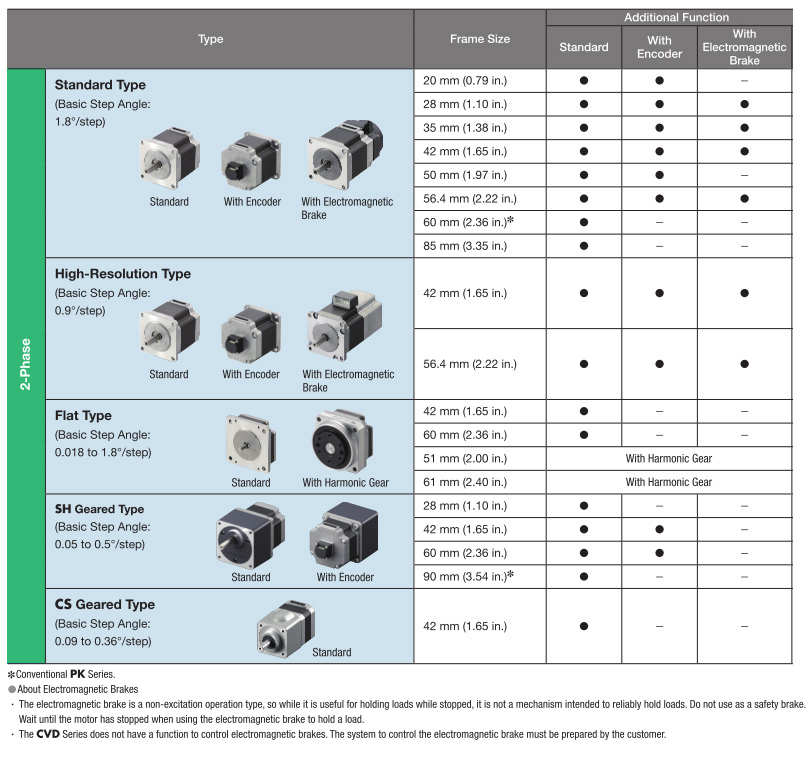

PKP Series 2-Phase Bipolar Stepper Motors

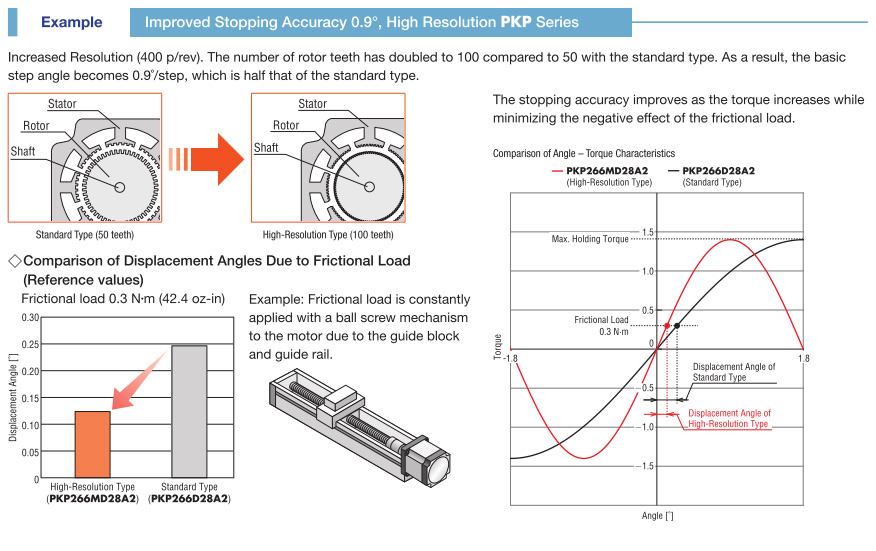

High-Torque 2-Phase bipolar stepper motors and Spur Gear (SH Type) stepper motors offer the optimum performance and value. In addition to offering high torque, the PKP series stepper motors offer more variety of electrical specifications, more frame sizes, encoder options and electromagnetic brake options for the right solution in stepper motors.

- Offers 1.2 ~ 1.7 Time More Torque

- 1.8° (200 pulse/rev) & 0.9° (400 pulse/rev)

- SH Geared (Spur) Type for Inertia Matching & Higher Torque

- Bipolar (4 lead wires)

- Encoders - 200 or 400 Lines of Resolution

- Electromagnetic Brake Type

Driver Mounting Bracket

This is a DIN Rail mounting bracket for drivers with installation plates.

Driver Cover

This cover provides protection for the driver and prevents accidental contact. For use with right-angle type connector type with installation plate.

DC Power Supply Cable

Power Cable for CVD Driver.

0.5 m [1.6 ft] |

|

1 m [3.3 ft] |

|

2 m [6.6 ft] |

Driver Cable Set - RS-485 Communication Type

Power supply cable is used to connect the driver and the power supply. I/O signal cable is used to connect the driver and programmable controller.

*Cables required for 15W, 30W and 50W drivers, included with 100W driver

RS-485 Driver |

0.3 m |

|

1 m |

Motor - Driver Connector Cables

A cable that directly connects a connector-coupled motor and driver. A motor and driver can be directly connected using the connectors on both ends.

RS-485 Communication Cables

Communication cables for RS-485 type drivers.

Driver to Controller |

|

Driver to Driver |

Driver Cable Set - Pulse Input Type

As an accessory for DC input drivers, lead wires with a connector are available. These lead wires allow for easy connection of the motor, power supply and input/output signals. The connection cable set includes three connection cables (for motor, power supply and input/output signals).

Item |

Applicable Drivers |

CVD205, CVD206, CVD215, CVD223, CVD228 |

|

CVD242, CVD245 |

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.