AZX Series Equipped with Mechanical Absolute Encoder Servo Motors

AZX Series Servo Motors Equipped with Mechanical Absolute Encoder

These servo motors are equipped with a battery-free absolute encoder. They are suitable for continuous speed control or positioning applications with a large amount of travel since they achieve high torque in the high speed range. The basic operations are the same as the AZ Series, making combined use of equipment easy.

Stepper Motor Lineup

Output Power |

Motor Types |

Available Options |

Rated Torque |

Max. Instantaneous Torque |

||

Round Shaft (No Gear) |

Electromagnetic Brake |

180 oz-in |

1.27 N·m |

540 oz-in |

3.82 N·m |

|

| Planetary Geared | 50 ~ 220 lb-in |

5.72 ~ 25.7 N·m |

151 ~ 680 lb-in |

17.1 ~ 77.2 N·m |

||

Round Shaft (No Gear) |

Electromagnetic Brake |

270 oz-in |

1.91 N·m |

540 ~ 1020 oz-in |

3.82 ~ 7.16 N·m |

|

| Planetary Geared | 370 lb-in |

43.1 N·m |

152 ~ 1400 lb-in |

17.2 ~ 162 N·m |

||

* Geared Stepper Motor frame size.

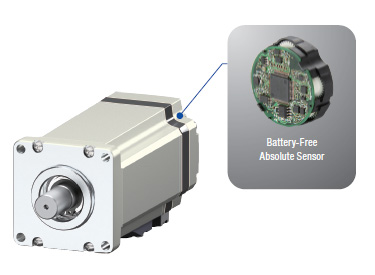

Battery-Free Absolute Encoder Equipped Servo Motor

The AZX Series is equipped with the same battery-free mechanical absolute encoder (ABZO sensor) as the AZ Series. These are dedicated servo motors for positioning and continuous operation.

- Mechanical Type Encoder

Holds positioning information even when powered off - Multi-Turn Absolute Encoder

Absolute position detection is possible with ±900 rotations (1800 rotations) of the motor shaft from the reference home position

No External Sensors Required

Thanks to the absolute system, a home sensor or external sensor is not required.

Advantages

- High-Speed Return-to-Home + Improved Return-to-Home Acuracy

- Reduced Cost

- Simple Wiring

- Not Affected by External Sensor Malfunctions

Battery Free

No Battery is necessary for a mechanical-type encoder. Positioning information is managed mechanically by the ABZO sensor.

Advantages

- No Battery Replacement Required

- No Battery Installation Space Required (Unlimited Driver installation possibilities)

- Safe for Oversease Shipping

Planetary Gear Servo Motors (PS)

High Performance Geared Servo Motors

These geared motors with high permissible torque fully utilize the motor output torque.

Low Backlash

The backlash is 15 arc minutes (0.25°) max. These motors can be used in a wide range of applications.

Electromagnetic Brake Option

These motors incorporate a non-excitation type electromagnetic brake. When power is accidentally cut off due to a blackout or other unexpected events, the electromagnetic brake holds the load in position to prevent it from dropping or moving.

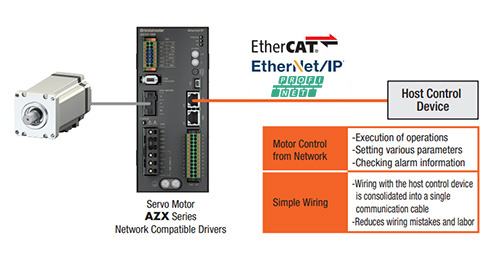

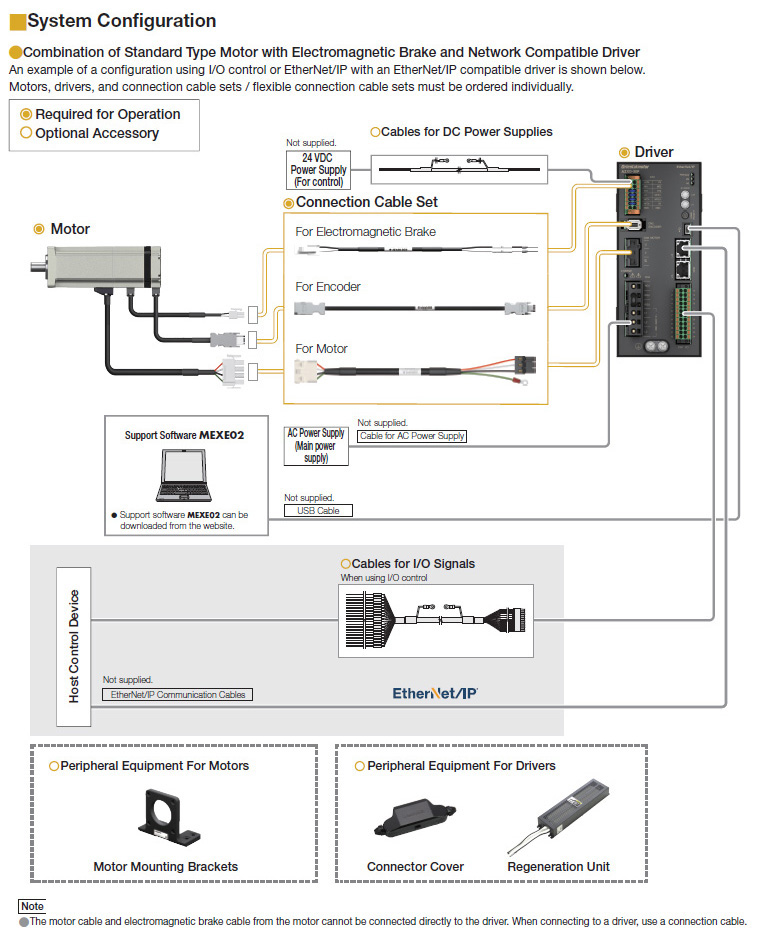

Network Compatible Drivers

These drivers are EtherCAT, EtherNet/IP, or PROFINET-compatible. The host control device and driver are connected with one communication cable, reducing wiring.

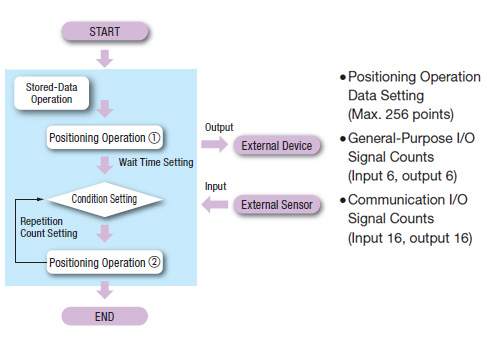

Sequence Function Simplifies Programming

AZX Series positioning operations come with a variety of sequence functions, such as a timer setting between operations and linked operation, conditional branching, and loop counting. These can be set using the support software MEXE02, which helps simplify the host system’s sequence program.

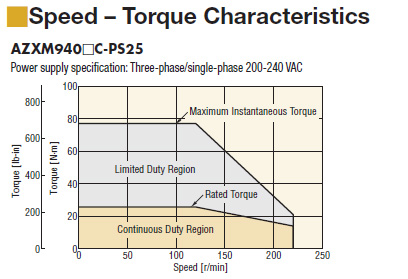

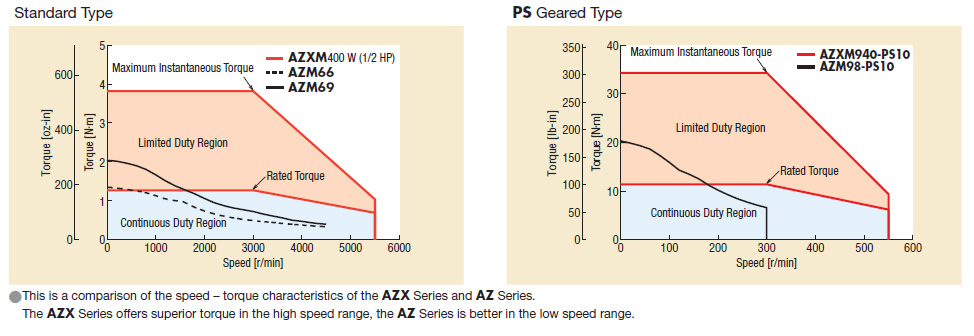

Achieves High Torque in the High Speed Range

The AZX Series achieves high torque in the high speed range. It is suitable for positioning applications with a large amount of travel (e.g.: ball screw driving).

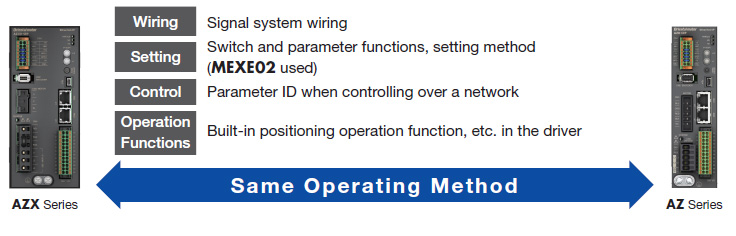

The Basic Operations are the Same as the AZ Series

Using the AZX Series and AZ Series together in the same equipment can eliminate the work of operational changes.

AZX Series AC Input Drivers

The AZXD Servo Motor Drivers are suitable for continuous speed control or positioning applications with a large amount of travel since they achieve high torque in the high speed range. These drivers are EtherCAT, EtherNet/IP, or PROFINET-compatible. The host control device and driver can be connected with one EtherCAT, EtherNet/IP, or PROFINET communication cable, reducing wiring. Advanced operation and function control are included through our MEXE02 software (free download). The basic operations are the same as the AZ Series, making combined use of equipment easy.

- Built-in Protective Functions

- Monitoring Functions

- Single-Phase/Three-Phase 200-240 VAC

- For use with AC Input AZX Series Motors

![]()

![]()

![]()

Connection Cables

These cables are used to connect or extend the distance between the motor and driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Mounting Brackets

Mounting brackets are convenient for installation of PS geared type servo motor.

System Configuration

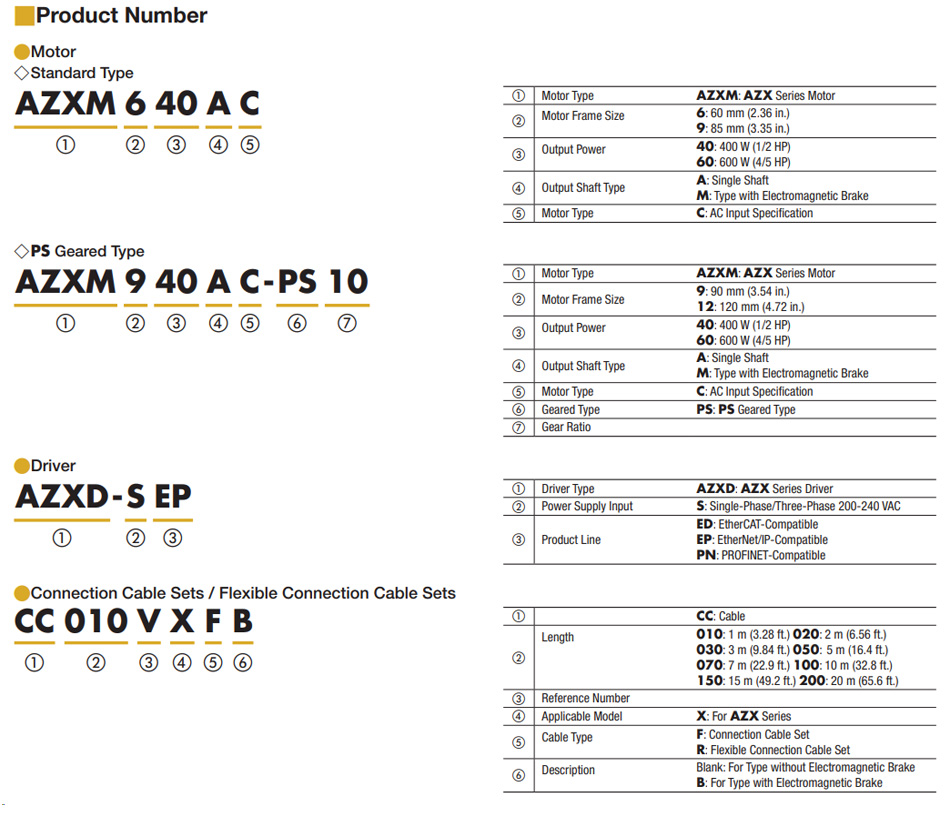

Part Number Code

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.