PKP Series 2-Phase Unipolar Stepper Motors

PKP Series 2-Phase Unipolar Stepper Motors

High-torque, 2-phase unipolar stepper motors and Spur Gear (SH Type) stepper motors offer the optimum performance and value. In addition to offering high torque, the PKP series stepper motors offer more variety of electrical specifications, more frame sizes and encoder options for the right solution in stepper motors.

- Offers 1.2 ~ 1.7 Time More Torque

- 1.8° (200 pulse/rev) or 0.9° (400 pulse/rev)

- SH Geared (Spur) Type for Inertia Matching & Higher Torque

- Unipolar (6 lead wires)

- Encoders - 200 or 400 Lines of Resolution

- Electromagnetic Brake Option

Stepper Motor Lineup

Frame Size |

Motor Types |

Available Options |

Current per Phase |

Lead Wires |

Max. Holding Torque |

|

Standard Type (1.8°) |

Encoder |

0.5 or 0.6 A |

5 |

1.98 ~ 3.6 oz-in |

0.014 ~ 0.026 N·m |

|

Standard Type (1.8°) |

Encoder |

0.95 A |

6 |

10.6 ~ 19.1 oz-in |

0.075 ~ 0.135 N·m |

|

High-Resolution Type (0.9°) |

Encoder |

9.9 ~ 17.5 oz-in |

0.07 ~ 0.124 N·m |

|||

Geared Type |

- |

42 ~ 112 oz-in |

0.3 ~ 0.8 N·m |

|||

Standard Type (1.8°) |

Encoder |

1.2 A |

6 |

28 ~ 52 oz-in |

0.2 ~ 0.37 N·m |

|

Standard Type (1.8°) |

Encoder |

0.8 ~ 2 A |

6 |

35 ~ 106 oz-in |

0.25 ~ 0.75 N·m |

|

High-Resolution Type (0.9°) |

Encoder |

1.2 A |

36 ~ 92 oz-in |

0.26 ~ 0.65 N·m |

||

Geared Type |

- |

0.95 A |

28.32 ~ 113.29 oz-in |

0.2 ~ 0.8 N·m |

||

|

|

Standard Type (1.8°) |

Encoder |

1 or 2 A |

6 |

72 ~ 280 oz-in |

0.51 ~ 2 N·m |

Geared Type |

- |

1 or 2 A |

141 ~ 560 oz-in |

1 ~ 4 N·m |

||

Standard Type (1.8°) |

- | 2 ~ 4.5 A |

6 |

368 ~ 1024 oz-in | 2.6 ~ 7.3 N·m | |

*Geared stepper motor frame size.

Standard Type Stepper Motors (1.8°/Step)

- 0.79 in. (20 mm)

- 1.10 in. (28 mm)

- 1.38 in. (35 mm)

- 1.65 in. (42 mm)

- 2.22 in. (56.4 mm)

- 3.35 in. (85 mm)

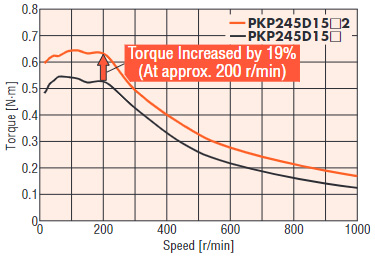

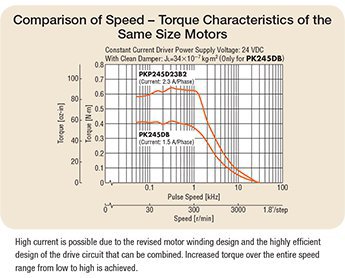

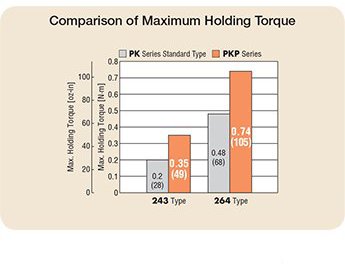

High-Torque PKP Series Stepper Motors

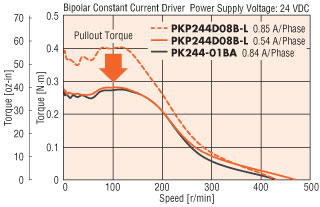

After revising the magnetic design and structure design of the PKP Series, it products much more torque than the conventional motors of the same size. In addition, torque can be increased in the high-speed range by using high current motors.

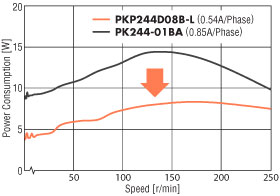

Reduced Power Consumption and Heat Output

If the running current of a PKP Series stepper motor is decreased and the motor is operated at the same torque as the PK Series standard type, current consumption and heat output can be reduced.

Characteristics Diagrams of Decreased Running Current in PKP Series Stepper Motors

Power Consumption Reduced by 20% (at low speed)

Comparison of driver power consumption when low speed torque is tailored to the PK Series standard type stepper motor.

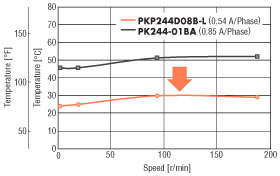

Temperature Increases of 10°C (18°F) and More are Suppressed

Comparison of stepper motor surface heat output when low-speed torque is tailored to the PK Series standard type

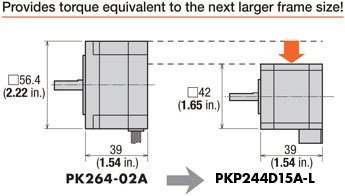

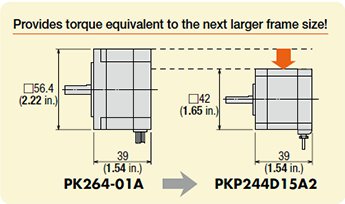

Downsizing

The PKP Series stepper motors provide torque equivalent to a stepper motor of the next larger frame size, contributing to downsizing of equipment.

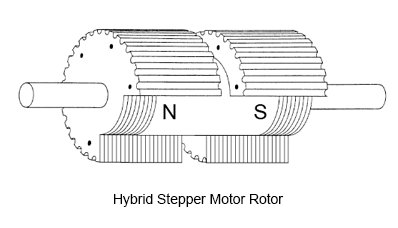

Utilizing Hybrid Stepper Motor Technology

A hybrid stepper motor is a combination of the variable reluctance and permanent magnet type motors. The rotor of a hybrid stepper motor is axially magnetized like a permanent magnet stepper motor, and the stator is electromagnetically energized like a variable reluctance stepper motor. Both the stator and rotor are multi-toothed.

A hybrid stepper motor has an axially magnetized rotor, meaning one end is magnetized as a north pole, and the other end a south pole. Toothed rotor cups are placed on each end of the magnet, and the cups are offset by half of a tooth pitch.

High-Resolution Type Stepper Motors (0.9°/step)

- 1.10 in. (28 mm)

- 1.65 in. (42 mm)

- 2.22 in. (56.4 mm)

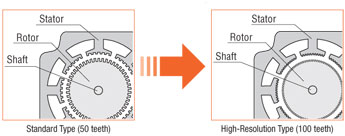

Increased Resolution (Compared to Standard Type)

The number of rotor teeth has doubled to 100 compared to 50 with the standard type stepper motor. As a result, the basic step angle becomes 0.9°/step which is half that of the standard type stepper motor.

These high resolution stepper motors have half the step angle of standard stepper motors. The high resolution type increases motor resolution from 200 steps/revolution to 400 steps/revolution. Smaller step angles can be achieved by half-step driving or microstep driving. Other than having twice as many rotor teeth as standard stepper motors, all other structures are exactly the same as standard stepper motors.

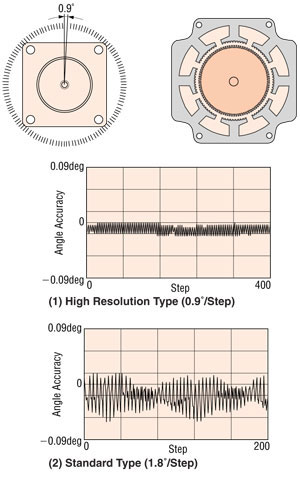

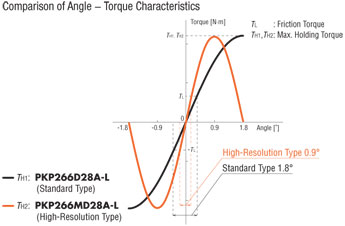

Improved Stopping Accuracy (Compared to Standard Type)

The stopping accuracy improves as the torque increases while minimizing the negative effect of the frictional load.

Downsizing

The PKP Series stepper motors provide torque equivalent to a stepper motor of the next larger frame size, contributing to downsizing of equipment.

Avoidance of Resonance Regions

If the pulse speed is within resonance region, vibration may increase. Resonance regions can be avoided by switching to a 0.9° high-resolution type stepper motor.

SH (Spur) Geared Type Stepper Motors

- 1.65 in. (42 mm)

- 2.36 in. (60 mm)

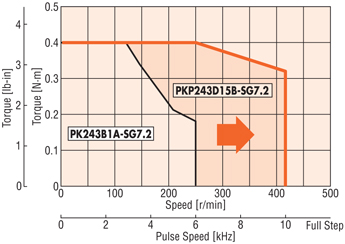

Broader Permissible Speed Range than Conventional Products

The New SH geared lineup now offers up to 60% more speed than current conventional models and is effective for increasing torque, achieving higher resolution and reducing vibration.

Backlash Accuracy Guaranteed

Backlash, which was a reference value in conventional models, is now a specification value.

Unit = arc min (degrees)

Frame Size |

Gear Ratio |

3.6 |

7.2 |

9 |

10 |

18 |

36 |

28 mm (1.10 in.) |

- |

90 (1.5°) |

|||||

42 mm (1.65 in.) |

90 (1.5) |

60 (1°) |

|||||

60 mm (2.36 in.) |

70 (1.17) |

45 (0.75°) |

|||||

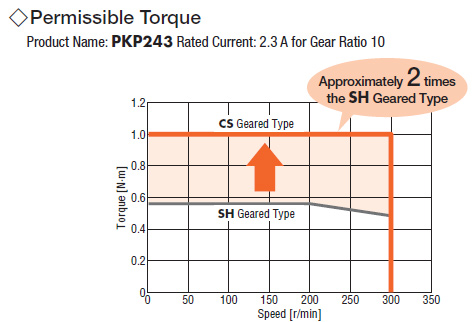

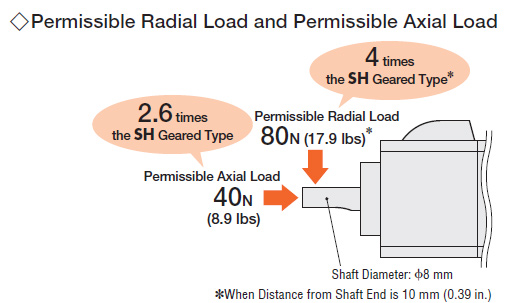

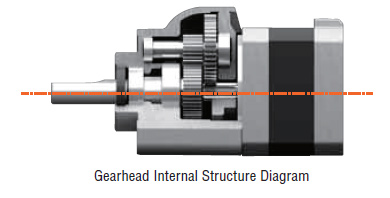

CS (Spur with Center Shaft) Geared Type Stepper Motors

- 1.10 in. (28 mm)

Increased Permissible Torque and Load

The CS geared type has increased torque and a large shaft for greater loads without the requirement for a larger gear frame size.

As shown in the structural drawing, by losing gears, the output shaft can be placed at the central axis.

Encoder Equipped Stepper Motors (1.8°)

- 0.79 in. (20 mm)

- 1.10 in. (28 mm)

- 1.38 in. (35 mm)

- 1.65 in. (42 mm)

- 2.22 in. (56.4 mm)

Encoder Type Stepper Motors

A rotary encoder is an electro-mechanical device that converts the angular position of a shaft to an analog or digital code. There are two main types: absolute and incremental. Oriental Motor offers incremental types (Line Driver or Voltage (TTL equivalent)) as a standard product for our stepper motors. For an absolute encoder solution, use the AZ Series. For other standard product encoder offerings and motors that correct themselves, contact technical support for assistance.

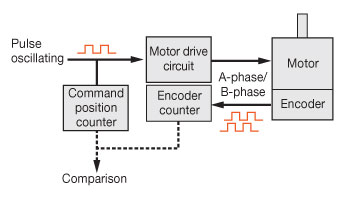

An incremental encoder provides the incremental change in position of the encoder to the counting electronics. Stepper motors with incremental encoders make it possible to monitor the present position and detect for errors. Position monitoring can be used to detect the position of the motor. For instance, to confirm normal operations, compare commanded position to the actual position.

3-Channel Encoders

Use the Index signal for the return-to-home operation. By using the Index signal, the return-to-home point will be detected with higher accuracy than single use of the return-to-home sensor. The index channel is an optional output channel which provides one pulse per revolution.

Line Driver Output Type

The Line Driver output offers excellent noise resistance because of the differential output and is capable of longer wiring distance compared to the voltage output.

Detecting for Errors

An incremental encoder works by providing an A and B pulse output. The counting is done through external electronics. Here, the encoder counter is compared to the commanded position counter (third party electronics). The point where the counting begins depends on the counter in the external electronics and not on the position of the encoder.

Voltage (TTL Equivalent) or Line Driver Type

R2E, R2F & R2EL, R2FL

200 or 400 p/rev

3 Channel

Compact & Space Saving

Oriental Motor Original

Encoder Specifications

Encoder Code |

Voltage (TTL Equivalent) |

Line Driver |

|||

R2E |

R2F |

R2EL |

R2FL |

||

Type |

Incremental |

||||

Resolution |

200 P/R |

400 P/R |

200 P/R |

400 P/R |

|

Output |

A-phase, B-phase, Z-phase (3ch) |

||||

Input Current |

45 mA or less |

30 mA or less |

|||

Input Voltage |

5 VDC ±10% |

||||

Output Type |

Voltage (TTL equivalent) |

Line Driver |

|||

Output Voltage |

Low |

0.5 VDC or less |

|||

High |

4.3 VDC or more (with no load) |

||||

Response Frequency |

100 kHz |

||||

Electromagnetic Brake Equipped Stepper Motors (1.8° or 0.9°)

- 1.10 in. (28 mm)

- 1.38 in. (35 mm)

- 1.65 in. (42 mm)

- 2.22 in. (56.4 mm)

Electromagnetic Brake Option

These products have built-in power-off activated electromagnetic brakes. When power is accidentally cut off due to a blackout or other unexpected events, the electromagnetic brake holds the load in position to prevent it from dropping or moving. Also, when the motor is at standstill, it is held by the electromagnetic brake. It is possible to suppress the heat generated from the motor by turning off the motor current.

Product Name |

PK22 |

PKP23 · PKP24 |

PKP26 |

Type |

Power Off Activated Type |

||

Power Supply Voltage |

24 VDC ± 5% |

||

Power Supply Current (A) |

0.05 |

0.07 |

0.23 |

Static Friction Torque (N·m) |

0.08 |

0.3 |

1.5 |

Brake Operating Time (ms) |

20 |

||

Brake Release Time (ms) |

50 |

||

Time Rating |

Continuous |

||

For product names, product name-identifying characters are used.

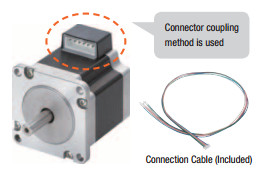

Stepper Motor Connection

Compact and Flat Connector

The PKP Series 1.65 in. [42 mm] and 2.22 in. [56.4 mm] frame size are available with a compact and flat connector, which shortens the length of the connectors overhang. In addition, the degree of freedom for the cable outlet direction has been increased because the outlet direction points upward.

Standard Motor Connector

Stepper motor lead wire connector can be inserted*1 and the locking mechanism prevents accidental removal*2

Wiring Configuration Options

- Unipolar - 6 lead wires

*1 Except for stepper motor frame size of 20 mm (0.79 in.)

*2 Only motor frame sizes of 35 mm (1.38 in.) 42 mm (1.65 in.), 56.4 mm (2.22 in.) and 60 mm (2.36 in.)

Comparison of the Flat Connector Type and the Connector Type For 2-Phase Stepper Motors

Type |

Flat Connector Type |

Connector Type |

|

Features |

Standard performance |

||

Permissible Radial Load (Max. value) |

42 mm | ||

| 56.4 mm | |||

Permissible Axial Load |

42 mm | ||

| 56.4 mm | |||

Speed - Torque Characteristics |

Example of comparison of Torque characteristics with the same size motor |

||

Motor Cables (*required)

This lead wire connection cable with a conveniently crimped connector is for connector-coupled motor, and for connecting motors and drivers.

Encoder cables required for encoder type motors.

Rotary Encoders

Small, thin, and lightweight stand-alone rotary encoders with an outer diameter of ϕ30 mm can be installed in tight spaces.

Stepper Motor Linear Actuator Attachment

Stepper Motor Linear Actuator Attachment is a linear motion mechanism with a lead screw and resin nut. It saves space and reduces design time compared to a custom-built mechanism. To use with 2-Phase and 5-Phase stepper motors PKP Series frame size 42mm (Round Shaft Type only).

Mounting Brackets

Mounting brackets are convenient for installation and securing a stepper motor or geared stepper motor.

Clean Dampers

Mechanical dampers suppress stepper motor vibration and improve high-speed performance. An inertia body and silicon gel are hermetically sealed in a plastic case.

(For use with Double Shaft motors)

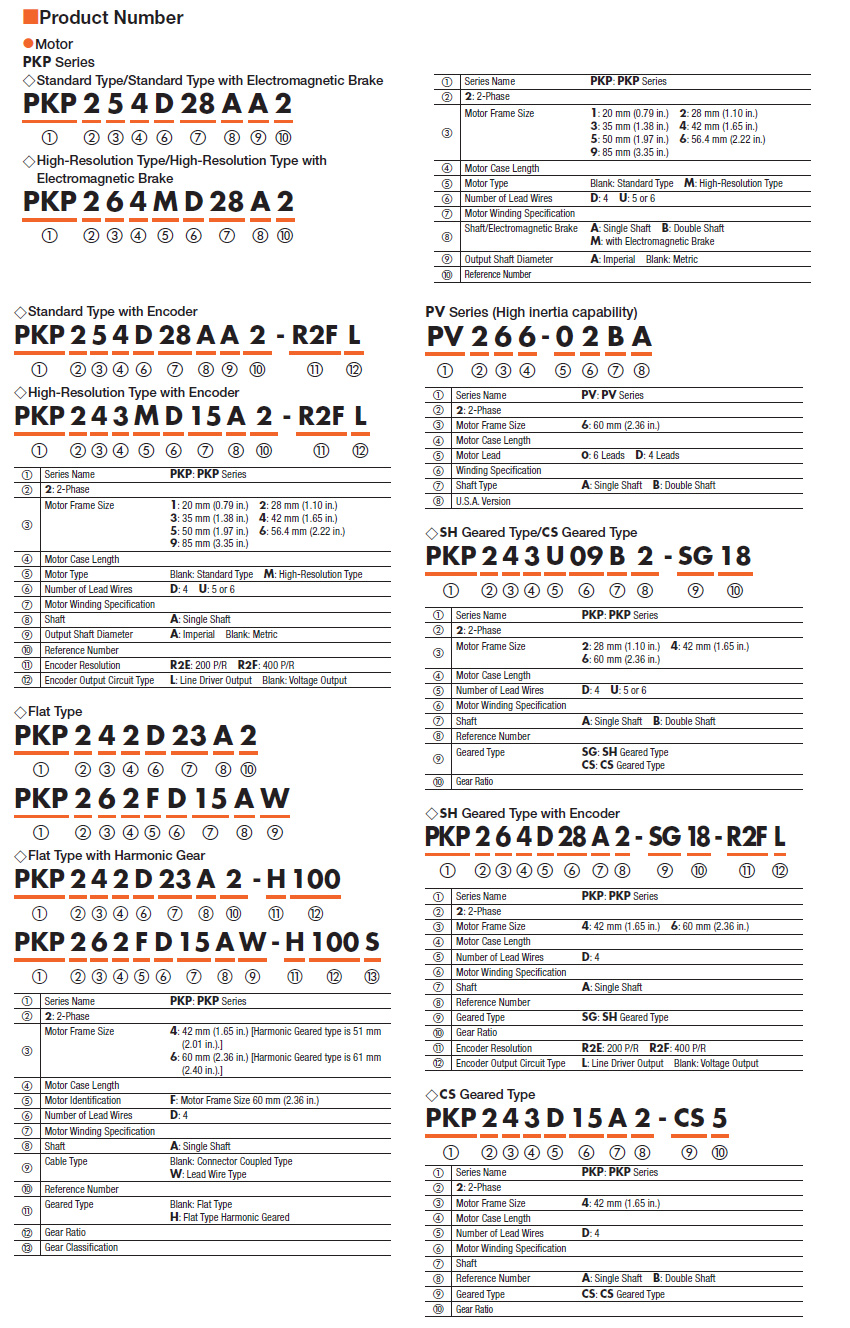

Product Number Code

PKP213U05A PKP213U05A-R2E PKP213U05A-R2EL PKP213U05B PKP214U06A PKP214U06A-R2E PKP214U06A-R2EL PKP214U06B PKP223MU09A PKP223MU09A-R2F PKP223MU09A-R2FL PKP223MU09B PKP223U09A2 PKP223U09A2-R2F PKP223U09A2-R2FL PKP223U09A-CS10 PKP223U09A-CS15 PKP223U09A-CS20 PKP223U09A-SG10 PKP223U09A-SG18 PKP223U09A-SG36 PKP223U09A-SG7.2 PKP223U09A-SG9 PKP223U09B2 PKP223U09B-CS10 PKP223U09B-CS15 PKP223U09B-CS20 PKP223U09B-SG10 PKP223U09B-SG18 PKP223U09B-SG36 PKP223U09B-SG7.2 PKP223U09B-SG9 PKP223U09M2 PKP225MU09A PKP225MU09A-R2F PKP225MU09A-R2FL PKP225MU09B PKP225U09A2 PKP225U09A2-R2F PKP225U09A2-R2FL PKP225U09B2 PKP225U09M2 PKP233U12A PKP233U12A-R2F PKP233U12A-R2FL PKP233U12B PKP233U12M PKP235U12A PKP235U12A-R2F PKP235U12A-R2FL PKP235U12B PKP235U12M PKP243MU09M PKP243MU12A2 PKP243MU12A2-R2F PKP243MU12A2-R2FL PKP243MU12B2 PKP243U08A2 PKP243U08A2-R2E PKP243U08A2-R2EL PKP243U08A2-R2F PKP243U08A2-R2FL PKP243U08B2 PKP243U09A2 PKP243U09A2-R2E PKP243U09A2-R2EL PKP243U09A2-R2F PKP243U09A2-R2FL PKP243U09A2-SG10 PKP243U09A2-SG18 PKP243U09A2-SG3.6 PKP243U09A2-SG36 PKP243U09A2-SG7.2 PKP243U09A2-SG9 PKP243U09B2 PKP243U09B2-SG10 PKP243U09B2-SG18 PKP243U09B2-SG3.6 PKP243U09B2-SG36 PKP243U09B2-SG7.2 PKP243U09B2-SG9 PKP243U09M PKP243U12A2 PKP243U12A2-R2E PKP243U12A2-R2EL PKP243U12A2-R2F PKP243U12A2-R2FL PKP243U12B2 PKP244MU12A2 PKP244MU12A2-R2F PKP244MU12A2-R2FL PKP244MU12B2 PKP244MU12M PKP244U08A2 PKP244U08A2-R2E PKP244U08A2-R2EL PKP244U08A2-R2F PKP244U08A2-R2FL PKP244U08B2 PKP244U12A2 PKP244U12A2-R2E PKP244U12A2-R2EL PKP244U12A2-R2F PKP244U12A2-R2FL PKP244U12B2 PKP244U12M PKP245MU12A2 PKP245MU12A2-R2F PKP245MU12A2-R2FL PKP245MU12B2 PKP245U08A2 PKP245U08A2-R2E PKP245U08A2-R2EL PKP245U08A2-R2F PKP245U08A2-R2FL PKP245U08B2 PKP245U12A2 PKP245U12A2-R2E PKP245U12A2-R2EL PKP245U12A2-R2F PKP245U12A2-R2FL PKP245U12B2 PKP245U12M PKP246MU12A2 PKP246MU12A2-R2F PKP246MU12A2-R2FL PKP246MU12B2 PKP246U12A2 PKP246U12A2-R2E PKP246U12A2-R2EL PKP246U12A2-R2F PKP246U12A2-R2FL PKP246U12B2 PKP246U12M PKP246U16A2 PKP246U16A2-R2E PKP246U16A2-R2EL PKP246U16A2-R2F PKP246U16A2-R2FL PKP246U16B2 PKP254U20AA2 PKP254U20AA2-R2E PKP254U20AA2-R2EL PKP254U20AA2-R2F PKP254U20AA2-R2FL PKP254U20BA2 PKP256U20AA2 PKP256U20AA2-R2E PKP256U20AA2-R2EL PKP256U20AA2-R2F PKP256U20AA2-R2FL PKP256U20BA2 PKP258U20AA2 PKP258U20AA2-R2E PKP258U20AA2-R2EL PKP258U20AA2-R2F PKP258U20AA2-R2FL PKP258U20BA2 PKP264MU20M PKP264U10A2 PKP264U10A2-R2E PKP264U10A2-R2EL PKP264U10A2-R2F PKP264U10A2-R2FL PKP264U10A2-SG10 PKP264U10A2-SG18 PKP264U10A2-SG3.6 PKP264U10A2-SG36 PKP264U10A2-SG7.2 PKP264U10A2-SG9 PKP264U10AA2 PKP264U10B2 PKP264U10B2-SG10 PKP264U10B2-SG18 PKP264U10B2-SG3.6 PKP264U10B2-SG36 PKP264U10B2-SG7.2 PKP264U10B2-SG9 PKP264U10BA2 PKP264U20A2 PKP264U20A2-R2E PKP264U20A2-R2EL PKP264U20A2-R2F PKP264U20A2-R2FL PKP264U20A2-SG10 PKP264U20A2-SG18 PKP264U20A2-SG3.6 PKP264U20A2-SG36 PKP264U20A2-SG7.2 PKP264U20A2-SG9 PKP264U20AA2 PKP264U20B2 PKP264U20B2-SG10 PKP264U20B2-SG18 PKP264U20B2-SG3.6 PKP264U20B2-SG36 PKP264U20B2-SG7.2 PKP264U20B2-SG9 PKP264U20BA2 PKP264U20M PKP266MU20M PKP266U10A2 PKP266U10A2-R2E PKP266U10A2-R2EL PKP266U10A2-R2F PKP266U10A2-R2FL PKP266U10AA2 PKP266U10B2 PKP266U10BA2 PKP266U20A2 PKP266U20A2-R2E PKP266U20A2-R2EL PKP266U20A2-R2F PKP266U20A2-R2FL PKP266U20AA2 PKP266U20B2 PKP266U20BA2 PKP266U20M PKP268MU20M PKP268U10A2 PKP268U10A2-R2E PKP268U10A2-R2EL PKP268U10A2-R2F PKP268U10A2-R2FL PKP268U10B2 PKP268U20A2 PKP268U20A2-R2E PKP268U20A2-R2EL PKP268U20A2-R2F PKP268U20A2-R2FL PKP268U20B2 PKP268U20M PKP2913U20A PKP2913U20AA PKP2913U20B PKP2913U20BA PKP2913U40A PKP2913U40AA PKP2913U40B PKP2913U40BA PKP296U20A PKP296U20AA PKP296U20B PKP296U20BA PKP296U30A PKP296U30AA PKP296U30B PKP296U30BA PKP296U45A PKP296U45AA PKP296U45B PKP296U45BA PKP299U20A PKP299U20AA PKP299U20B PKP299U20BA PKP299U30A PKP299U30AA PKP299U30B PKP299U30BA PKP299U45A PKP299U45AA PKP299U45B PKP299U45BA

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.