Hybrid Stepper Motors and the αSTEP Hybrid Control Systems

All motors convert electrical power, volts and amps, into mechanical power, torque and speed. The unique feature of stepper motors is that they can be very accurately controlled in terms of speed and rotation angle. Stepper motors are brushless DC motors, and as such, require an electronic driver to commutate the windings. In order to control the rotation, electrical pulses are input into the driver, and the motor rotates one step for each pulse. The excellent stability of the motor results in a simple control circuit, since the motor can be run open-loop and no feedback is required.

There are three types of stepper motors; variable reluctance, permanent magnet and hybrid stepper motors. This article will focus on hybrid stepper motors as well as Oriental Motor's AlphaStep Hybrid Control System for stepper motors.

What is a Hybrid Stepper Motor?

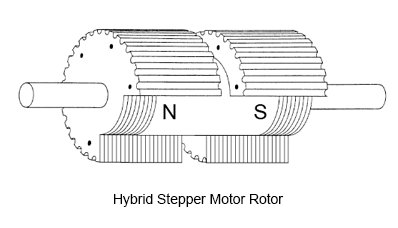

A hybrid stepper motor is a combination of the variable reluctance and permanent magnet type motors. The rotor of a hybrid stepper motor is axially magnetized like a permanent magnet stepper motor, and the stator is electromagnetically energized like a variable reluctance stepper motor. Both the stator and rotor are multi-toothed.

A hybrid stepper motor has an axially magnetized rotor, meaning one end is magnetized as a north pole, and the other end a south pole. Toothed rotor cups are placed on each end of the magnet, and the cups are offset by half of a tooth pitch.

Comparison of Stepper Motor Types

Advantages / Types of Stepper Motor |

Permanent Magnet |

Variable Reluctance |

Hybrid |

Step Angle |

7.5° or larger |

1.8° or smaller |

1.8° or smaller |

Output Torque |

Moderate |

Low |

High |

Detent Torque |

Yes |

No |

Yes |

Pulse Rate / Speed |

Low |

High |

High |

Acceleration / Response |

Slow |

Fast |

Fast |

Noise |

Quiet |

Loud |

Quiet |

Microstep |

Yes |

No |

Yes |

Design |

Simple |

Moderate |

Complex |

Oriental Motor offers three types of hybrid stepper motors:

Hybrid Control Systems

Oriental Motor's AlphaStep Hybrid Control System is a hybrid stepper motor and driver package offering improved response and reliability. The AlphaStep features a unique control system combining the benefits of "open loop control" and "closed loop control".

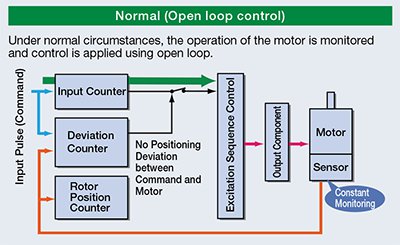

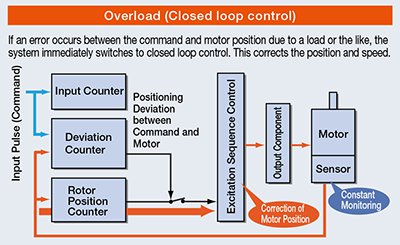

With the AlphaStep control system, the position of the motor is always monitored and then the driver automatically switches between the two types of control depending on the situation. Under normal circumstances the operation of the motor is monitored and control is applied using open loop like a standard stepper motor. If an error occurs between the command and motor position due to a load or the like, the system immediately switches to closed loop control like a servo motor. This corrects the position and speed maintaining the desired operation. The combination of these two control methods ensures high reliability and performance.

The AlphaStep Hybrid Control System is available on standard and geared AlphaStep Stepper Motors, AlphaStep Rotary Actuators, AlphaStep Linear Slides & Cylinders and AlphaStep Compact Linear Actuators.

Normally Operates in Open Loop Control for the Same Ease of Use as a Stepper Motor

High Response

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

Holding the Stop Position without Hunting

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

Tuning-Free

Because it is normally operated with open loop control, positioning is still possible without gain adjustment even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Switches to Closed Loop Control during Overload for More Reliable Operation like a Servo Motor

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

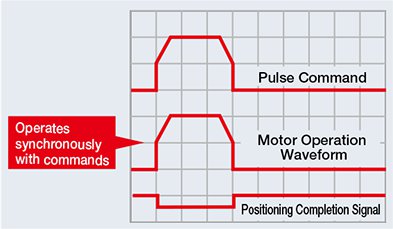

It operates synchronously with commands using open loop control during normal conditions. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.