Belt & Pulley System

For high precision applications, such as a belt & pulley system, where high response and quick positioning after load changes are needed without adjusting any gains or required tuning of the motor, Oriental Motor offers a wide range of stepper motor and tuning-free servo motors.

For system solutions requiring connection to an upper level controller, PLC or HMI, Oriental Motor offers several networked products to allow for easy control using I/O or RS-485 / Modbus (RTU) networks.

Applicable Products

Position Control Conveyor Belt Systems

For conveyors that require higher accuracy positioning Oriental Motor offers a wide range of Stepper Motor and Servo Motor solutions. Stepper motors, with their ability to product high torque at a low speed while minimizing vibration, are ideal for applications requiring quick positioning over a short distance. Servo motors are easy to operate and allow for smooth operation with large inertial loads and belt mechanisms. Servo motors are ideal for positioning over long distances using a flat torque characteristic from low to high speeds.

Type |

Features |

|

|

Positioning over short distance |

Stepper Motors are suitable for high accuracy positioning over a short distance and provide high torque even at low speeds. Stepper motors also offer very low vibration and a wide range of features and options such as gearheads, encoders and built-in controllers to meet the specific needs of your application. |

Positioning over long distance |

Servo Motors provide accurate positioning for quick moves or for a long distance moves. All feature a closed loop configuration ideal for variable loads and offer a wide range of gear options and braking or load holding options. The built-in controller (stored data) FLEX also helps for system configuration considerations. |

|

Geared Options

A wide range of gearing options are available to provide higher permissible inertia, higher resolution positioning and higher torque for index table and high inertia applications.

Geared Stepper Motors |

Geared Servo Motors |

Geared stepper motors not only achieve deceleration, high torque and high resolution, but they are capable of driving larger inertial loads compared to a standard motor. A wide range of gearing options are available: |

The servo motor has restrictions on permissible load inertia, but the geared type can be used to greatly increase the load size that can be driven. |

Networked - I/ O, RS-485 / Modbus (RTU) and Factory Automation Conveyor Applications

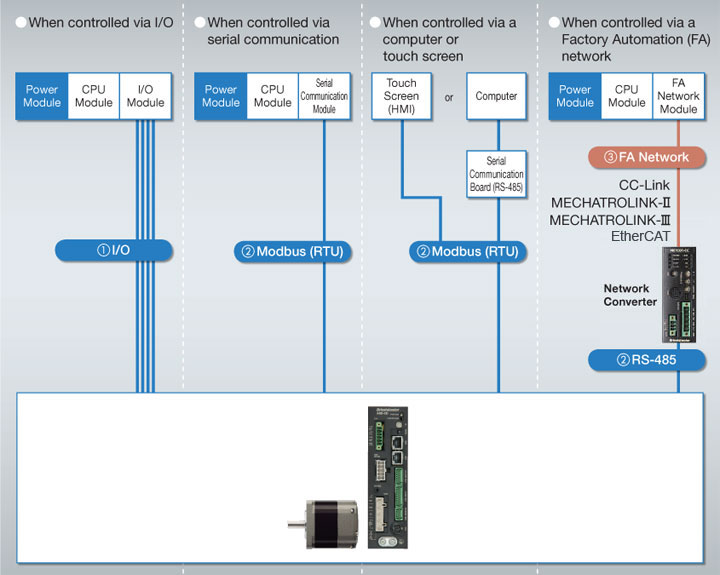

Oriental Motor offers Network products under the FLEX concept, meaning each product is equipped with an interface that connects to various master controllers featuring I/O, RS-485 / Modbus (RTU) or Factory Automation. Networked products enable operating data and parameters for each motor to be set at a Master Controller and sent to each driver. In addition, operation commands can be input send set using various communication methods to meet the need of a wide range of available Network Solutions.

Available Network Solutions

1. I/O - Allows the driver to be connected directly to a controller or PLC to configure the operating system with I/O.

2. RS-485 / Modbus (RTU) - Operating data and parameters can be set and operation commands can be input using RS-485 communication. Up to 31 drivers can be connected to each serial communication module. Also there is a function that enables the simultaneous start of multiple axes. The protocol supports Modbus (RTU), enable connection with devices such as a touch screen (HMI) or PCs.

3. Factory Automation Network - Use of a network converter (sold separately) enables support with CC-Link, MECHATROLINK or EtherCAT communication. Operating data and parameters can be set and operation commands can be input using various communication methods.

For Connecting to Factory Automation (FA) Networks

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Connection to FLEX-compatible products is completed with one RS-485 communication cable.

|

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)