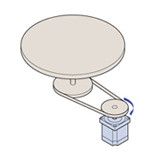

Material Agitator

For applications requiring constant torque over a wide speed range Oriental Motor recommends a brushless DC motor speed control system. Brushless DC motor systems provide constant torque from low to high speeds.

For system solutions requiring connection to an upper level controller, PLC or HMI, Oriental Motor offers several networked products to allow for easy control using I/O or RS-485 / Modbus (RTU) networks. Our brushless DC motor speed control systems also simply and easily connect to upper level controls.

Applicable Products

Speed Control Systems

For applications where the speed needs to controlled or vary during operation Oriental Motor offers Brushless DC Motors & Gear Motors (BLDC Motors) with a wide speed control range and constant torque regardless of load.

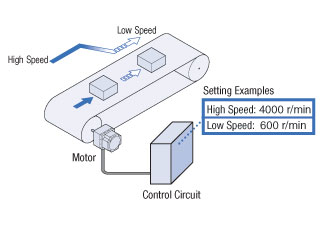

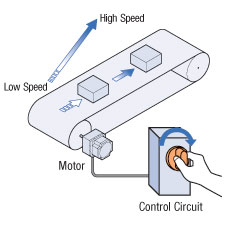

By combining a control circuit with the motor, speed changes can be performed. Speed control motors are optimal for switching between high speed and low speed operation and for arbitrary adjustment of speed.

Setting Multiple Speeds and Switching Speeds |

Arbitrarily Adjusting the Speed |

|

|

Type |

Features |

Output |

Speed Control |

Power |

|

Brushless DC Motors & Gear Motors (BLDC Motors) provide high speed stability, energy saving and space saving. Brushless DC motors also allow for stable speed control even with a fluctuating load and offer constant torque over a wide speed range. |

15 W (1/50 HP) |

80 ~ 4000 r/min |

Single-Phase 100-120 VAC Single-Phase 200-240 VAC Three-Phase 200-240 VAC 24 VDC 48 VDC |

Oriental Motor also offers a range of gear options to reduce the motor speed and generate greater torque.

Brushless DC (BLDC) Motor Gear Options

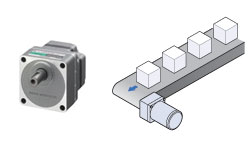

Parallel Shaft Gearheads |

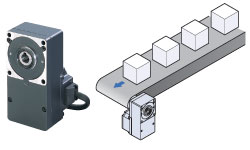

Hollow Shaft Flat Gearheads |

Parallel Shaft gearheads reduce the motor speed and generate greater torque. A wide range of gear ratios are available. |

Direct connection to the drive shaft is possible without using a connecting part which enables equipment space saving. In addition, the hollow shaft flat gearhead enables permissible torque without saturation even at high gear ratios, so the motor torque can be fully utilized. |

Networked - I/ O, RS-485 / Modbus (RTU) and Factory Automation Conveyor Applications

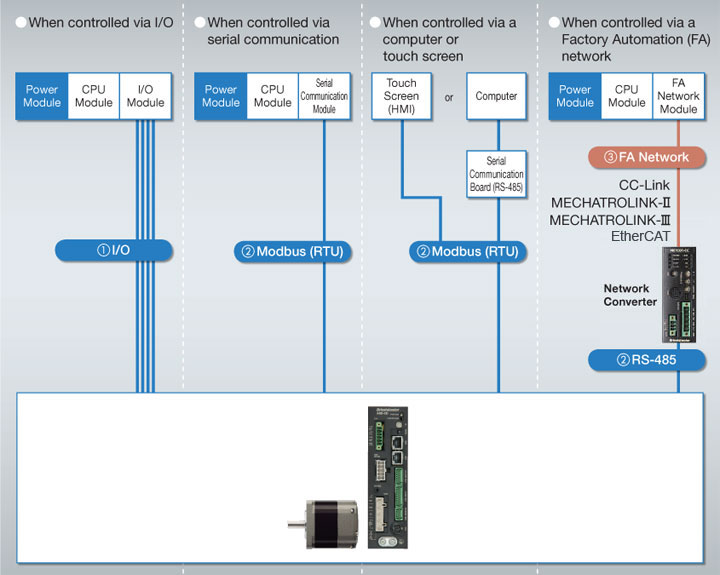

Oriental Motor offers Network products under the FLEX concept, meaning each product is equipped with an interface that connects to various master controllers featuring I/O, RS-485 / Modbus (RTU) or Factory Automation. Networked products enable operating data and parameters for each motor to be set at a Master Controller and sent to each driver. In addition, operation commands can be input send set using various communication methods to meet the need of a wide range of available Network Solutions.

Available Network Solutions

1. I/O - Allows the driver to be connected directly to a controller or PLC to configure the operating system with I/O.

2. RS-485 / Modbus (RTU) - Operating data and parameters can be set and operation commands can be input using RS-485 communication. Up to 31 drivers can be connected to each serial communication module. Also there is a function that enables the simultaneous start of multiple axes. The protocol supports Modbus (RTU), enable connection with devices such as a touch screen (HMI) or PCs.

3. Factory Automation Network - Use of a network converter (sold separately) enables support with CC-Link, MECHATROLINK or EtherCAT communication. Operating data and parameters can be set and operation commands can be input using various communication methods.

For Connecting to Factory Automation (FA) Networks

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Connection to FLEX-compatible products is completed with one RS-485 communication cable.

|

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)