Mobile Title

BLS Series Brushless DC Motors (BLDC Motors) - DC Input

The BLS Series combines an efficient, compact, and lightweight brushless motor with a slim, universal driver. This series meets simple variable speed requirements where space is limited. With compatibility across many types of gearheads, the BLS Series motor can easily replace AC motors that use the same gearhead.

- Simple, compact, and cost-effective

- IP65 or IP40

- Ideal for applications like conveyors and agitators

- Reduce electricity costs

- Standard or long-life type gearheads available: parallel shaft, hollow shaft flat gear or round shaft (no gear)

Brushless DC Motor (BLDC Motor) & Gear Motor Lineup

Output Power |

Gear Options |

Power Supply |

Rated Torque |

Speed Range |

|

Parallel Shaft |

24 VDC |

4.25 ~ 70.8 lb-in |

0.48 ~ 8 N·m |

100 ~ 2000 r/min Min: 0.6 [180:1] |

|

Parallel Shaft |

24 VDC |

3.54 ~ 53.1 lb-in |

0.4 ~ 6 N·m |

100 ~ 4000 r/min Min: 0.5 [200:1] |

|

Hollow Shaft Flat |

3.54 ~141.6 lb-in |

0.4 ~ 16 N·m |

|||

Round Shaft (no Gear) |

13.6 oz-in |

0.096 N·m |

|||

Parallel Shaft |

24 VDC |

7.08 ~ 88.51 lb-in |

0.8 ~ 10 N·m |

100 ~ 2000 r/min Min: 0.6 [180:1] |

|

Parallel Shaft |

24 VDC |

7.97 ~ 141.6 lb-in |

0.9 ~ 16 N·m |

100 ~ 4000 r/min Min: 0.5 [200:1] |

|

Hollow Shaft Flat |

7.2 ~ 283.2 lb-in |

0.81 ~ 32 N·m |

|||

Round Shaft (no Gear) |

27 oz-in |

0.191 N·m |

|||

Parallel Shaft |

24 VDC |

15.1 ~ 177 lb-in |

1.7 ~ 20 N·m |

100 ~ 2000 r/min Min: 0.6 [180:1] |

|

Parallel Shaft |

24 VDC |

15.1 ~ 265.5 lb-in |

1.7 ~ 30 N·m |

100 ~ 4000 r/min Min: 0.5 [200:1] |

|

Hollow Shaft Flat |

14.6 ~ 575.3 lb-in |

1.6 ~ 65 N·m |

|||

Round Shaft (no Gear) |

54.1 oz-in |

0.4 N·m |

|||

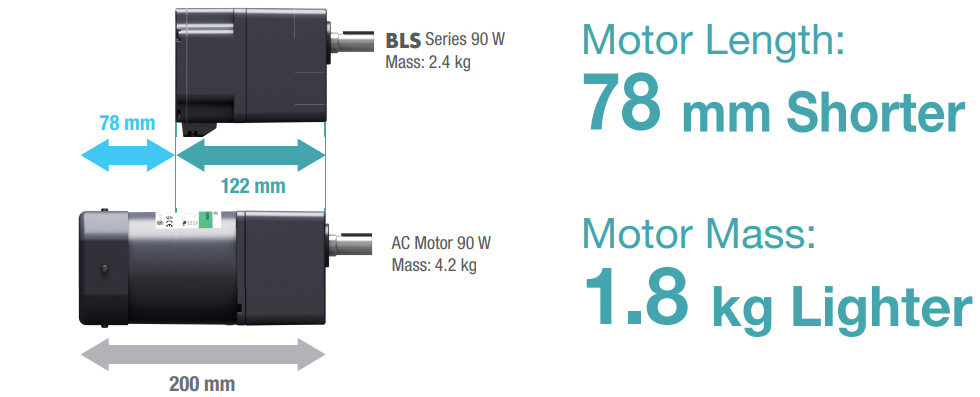

Smaller and Lighter Motor

Reduce Electricity Charges

Brushless motors are highly efficient, saving you energy. Electricity costs can be reduced by 20% compared to the use of an AC motor and inverter.

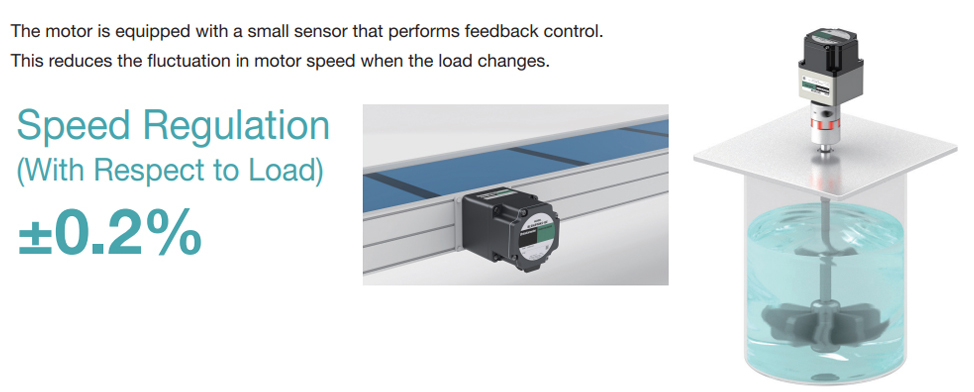

Reducing Speed Fluctuation

The motor is equipped with a small sensor that performs feedback control. This reduces the fluctuation in motor speed when the load changes.

Extending the Service Life of Your System

BLS Series has a longer service life than AC motors because of its highly efficient motor and low heat generation.

- One of the factors that affects a motor’s service life is the service life of grease on the bearing. Since the service life of grease is affected by heat, BLS Series with low heat generation extends the service life of its motor.

Brushless Motor BLS Series: 40,000 hours

AC Motor (Induction Motor): 30,000 hours

Conditions: Continuous and one-way operation, rated torque and constant load, rated speed, ambient temperature of 30˚C

24 VDC Input Makes it Easy to Deploy Equipment Globally and Design Safely

Easy to Expand Globally

- The same BLS Series products can be used worldwide.

- Unlike AC motors, there is no need to select and design according to the voltage/ frequency of each country.

- Not subject to the Low Voltage Directive

Safe Design, Low Noise

- 24 VDC input is below dangerous voltage (60 VDC)

- Significant reduction in safety measure designs

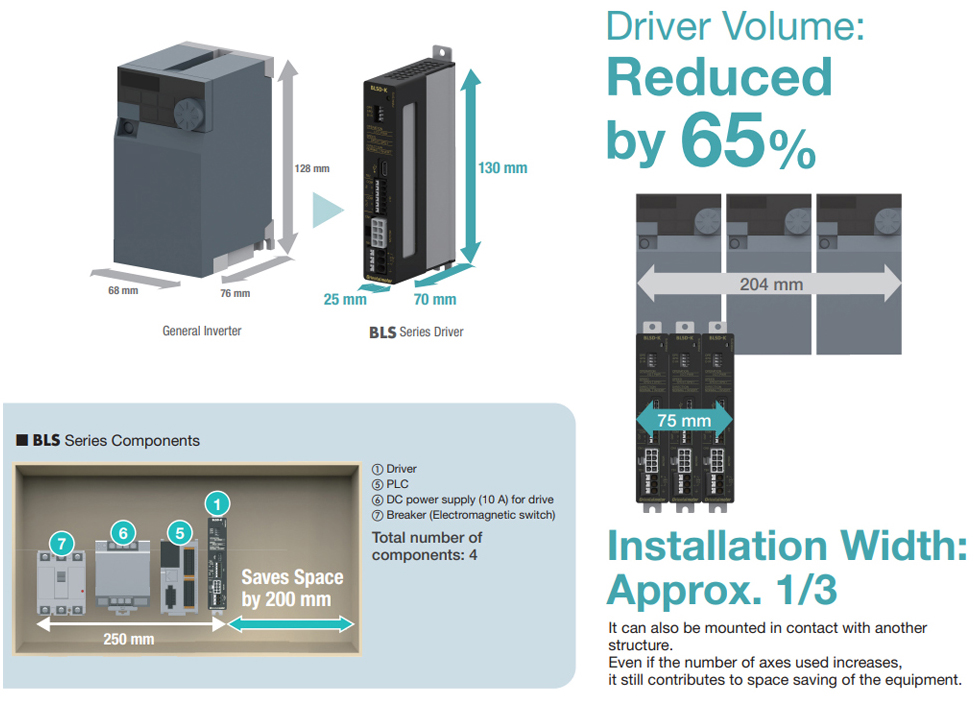

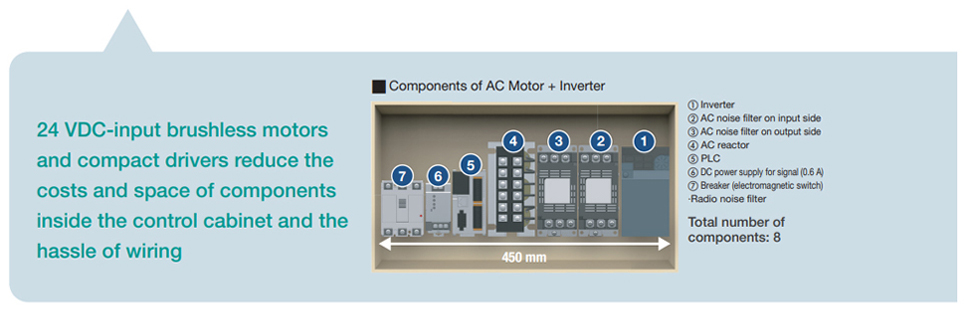

Compact System

- DC power supply is easy to control. The overall structure of the system is simple

- The control panel has also been simplified, making the entire system more compact

Slimmer Driver

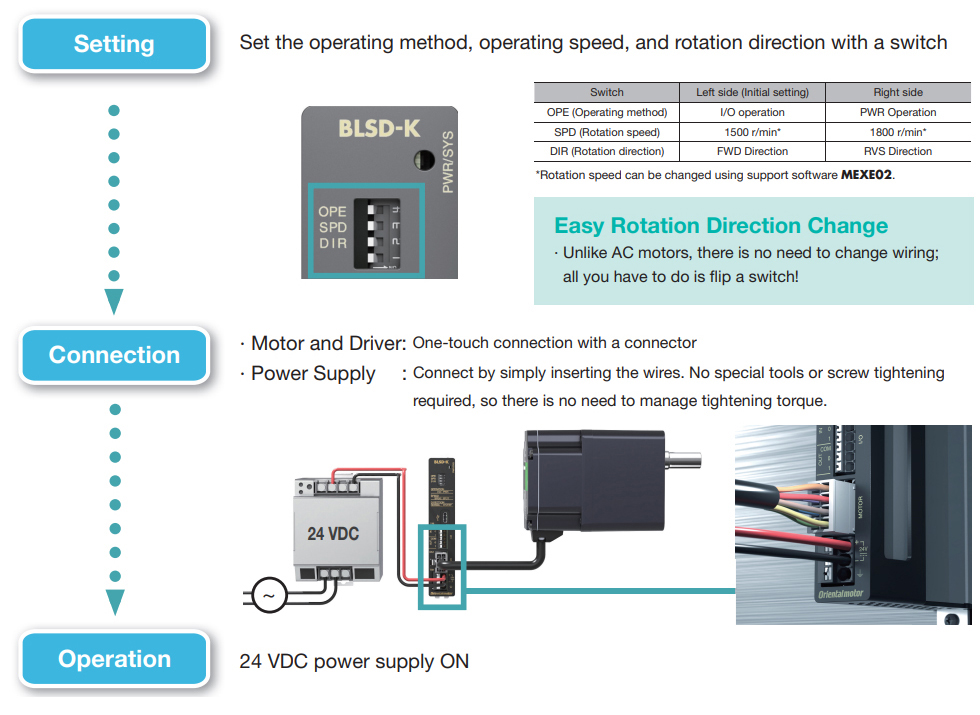

Simple Setup, Connection, and Operation

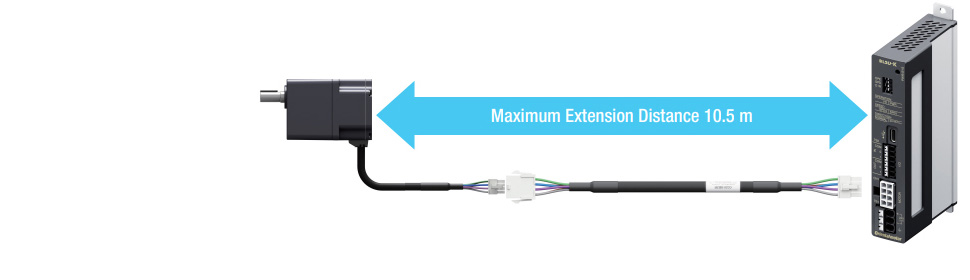

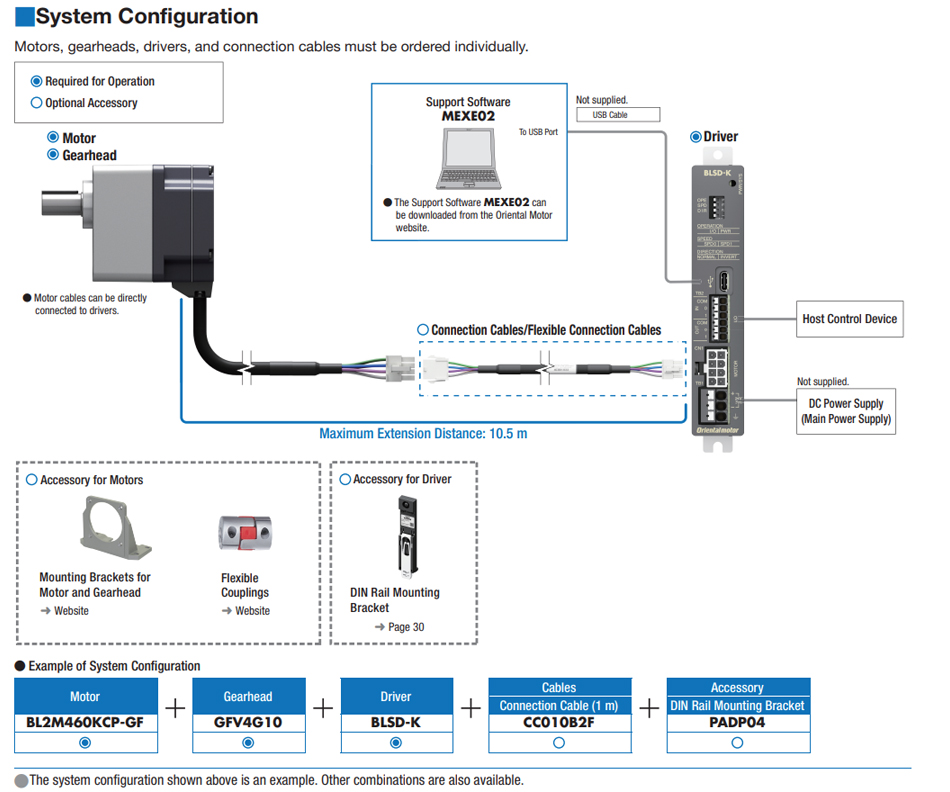

Cable Extension Distance 10.5 m

The maximum extension distance between the motor and driver can handle up to 10.5 m

One Driver Can Handle All Motor Outputs

All motors can be operated by a single driver model. Because parts can be standardized, inventory and maintenance can be reduced.

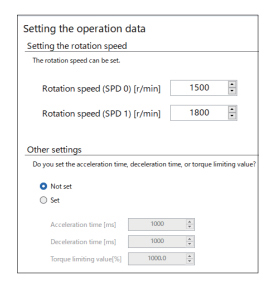

The Free Support Software MEXE02 Allows for More Advanced Setting and Monitoring

Using support software MEXE02 makes data setting and monitoring easier.

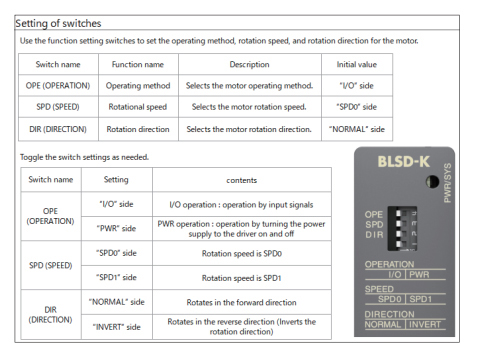

[Set Up] Operation Setting Support Wizard

- Switch Setting

Set the operating method, rotation speed and direction.

- Operation Data Setting

Modify the settings for rotation speed, acceleration/deceleration time, etc.

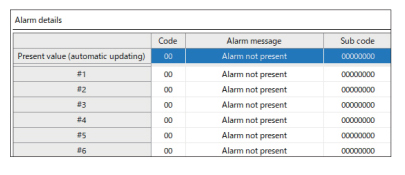

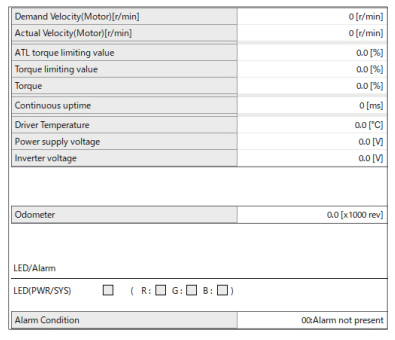

[Maintenance] Helpful Features for Diagnosis and Maintenance

- Alarm Monitoring

Check the alarm details.

- Status Check

Check the motor load, driver temperature, odometer, etc.

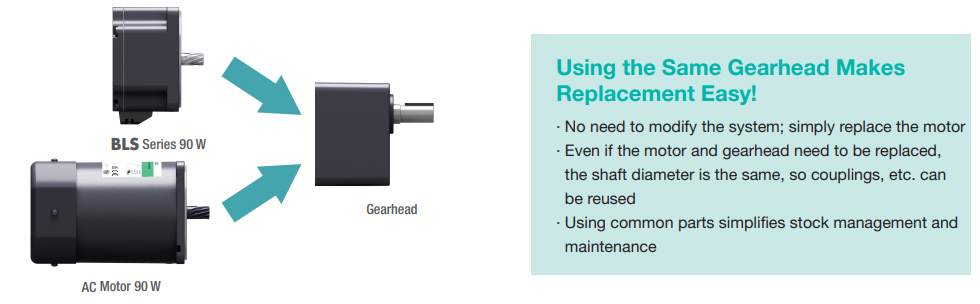

The Same Gearheads for AC Motors Can be Used*. Easily Replace the Motor without Having to Modify the System

For the same output power, the motor’s frame size and pinion specifications are identical to an AC motor*. The same gearheads (GN gearhead/GE gearhead) as an AC motor can be used*.

*For a standard (AC motor compatible) type.

Gearhead Selection Based on Intended Use

Type |

Standard (AC motor Compatible Type) |

High Strength, Long Life Type |

|

Appearance |

|

|

|

| Parallel Shaft Gearhead | Parallel Shaft Gearhead | Hollow Shaft Flat Gearhead | |

Overview |

The same gearhead as Oriental Motor’s AC motor Example: 4GN□K |

Gearheads for brushless motors High permissible torque, long service life Example: GFV4G□, GFS4G□FR |

|

Assembled Motor Output Power |

25 W, 40 W, 90 W |

30 W, 60 W, 120 W |

|

Max. Permissible Torque |

20 N·m |

30 N·m (Parallel shaft gearhead) 60 N·m (Hallow shaft flat gearhead |

|

Rated Life of a Gearhead |

5000 hours |

10000 hours |

|

Connection Cables/Flexible Connection Cables

These cables are used to connect the motor and the driver. When using an extension for the product cable, keep the overall cable length to 10.5 m or less.

Use the flexible connection cable in applications where the cable is bent and flexed repeatedly.

Connection Cables |

1 m |

|

| 2 m | ||

| 3 m | ||

| 5 m | ||

| 7 m | ||

10 m |

||

Flexible Connection Cables |

1 m |

|

| 2 m | ||

| 3 m | ||

| 5 m | ||

| 7 m | ||

10 m |

Flange Drive Adapter

Permissible load has been increased by mounting with a parallel shaft gearhead. Direct mounting of the rotation mechanism to wheels or rotary tables has been simplified, which helps reduce design time.

For use with Brushless Motors Parallel Shaft Gearhead 100 W (1/8 HP)/120 W (1/6 HP)

Flexible Couplings

These products are clamp type couplings used to connect a motor or gearhead shaft to the shaft of the equipment.

DIN Rail Mounting Bracket

Use this bracket when mounting BLS Series Brushless DC Motor Driver on a DIN rail.

Mounting Brackets

This is an aluminum alloy mounting bracket for parallel shaft geared motors.

Long, horizontal holes make it easy to make fine adjustments during installation.

| Model | Motor Frame Size |

| 60 mm | |

| 80 mm | |

| 80 mm | |

| 90 mm | |

| 90 mm |

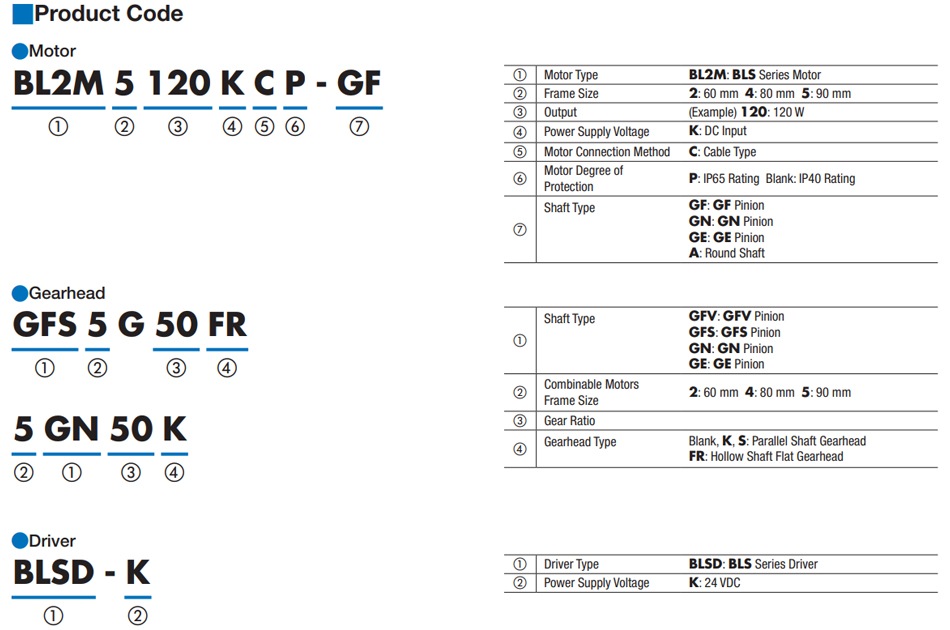

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.