Long Life AC Axial Fans - MRE Series

Long Life AC Axial Fans - MRE Series

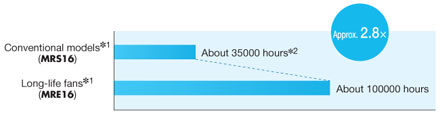

The MRE Series axial fan is available as a long life version of the MRS Series product. The MRE Series long-life fans have an expected life of 100,000 hours and are available with a low speed alarm.

Available in 6.30 in. (160 mm), 7.09 in. (180 mm) and 7.87 in. (200 mm) frame sizes.

- Long-Life - 100,000 hours

- Single-Phase 110/115 VAC, Single-Phase 220/230/240 VAC or Three-Phase 200/230 VAC

- Low Speed Alarm available

- Fan Kits available

Axial Fan Lineup

Frame Size |

Power Supply |

Options |

Max Air Flow |

Max Static Pressure |

||

Single-Phase 110/115 VAC |

Low Speed Alarm Fan Kit |

258 CFM |

7.3 m3/min |

0.63 inH20 |

157 Pa |

|

Single-Phase 220/230/240 VAC |

||||||

Three-Phase 220/230 VAC |

||||||

Single-Phase 110/115 VAC |

Low Speed Alarm Fan Kit |

452 CFM |

12.8 m3/min |

0.982 inH20 |

254 Pa |

|

Single-Phase 220/230/240 VAC |

||||||

Three-Phase 220/230 VAC |

||||||

Three-Phase 220/230 VAC |

Low Speed Alarm Fan Kit |

564 CFM |

16 m3/min |

1.2 inH20 |

300 Pa |

|

Long Life AC Axial Fans

These axial fans have an expected life of 100,000 hours (about 11 years). They reduce the increase in bearing temperature, inhibit grease deterioration and improve vibration resistance and shock resistance through bearing enlargement. They also increase the life of circuits and couplers and reduce failure rate. They are designed based on the concept of initial failure so that random failure and wear-out failure will not occur, allowing for 100,000 hours of continuous operation or more (survival rate of 90% or higher).

Long-life axial fans have an expected life of 100,000 hours, so the number of cooling fans that need replacing is decreased compared to conventional models.

*1 - The conventional models are T-MRS16-BTA-G and MRS16-BTA. The long-life fan is MRE16-BBHG.

*2 - Estimated life of 35000 hours with an ambient temperature of 60°C (140°F). Estimated life is an estimated value calculated using the bearing life-of-grease formula. Estimated life is different for each model.

Ideal for Hard to Service Environments

- Equipment that is continuously operational and cannot be stopped

- Areas that are hard to enter

- Equipment that is delivered to and installed in remote locations

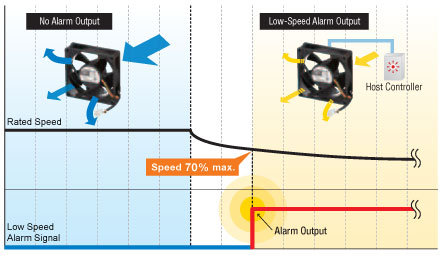

Low Speed Alarm Types

An alarm is output when the fan speed drops due to the service life of the fan or ingress of foreign objects. This makes it possible to order and replace the fan with a new one before it stops.

If multiple cooling fans are being used, it is possible to only replace the cooling fan with decreased cooling capacity. Even if the cooling capacity of the fan decreases, the effect on the equipment can be minimized.

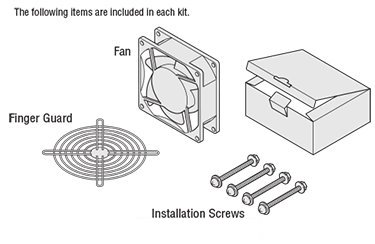

Fan Kits Available

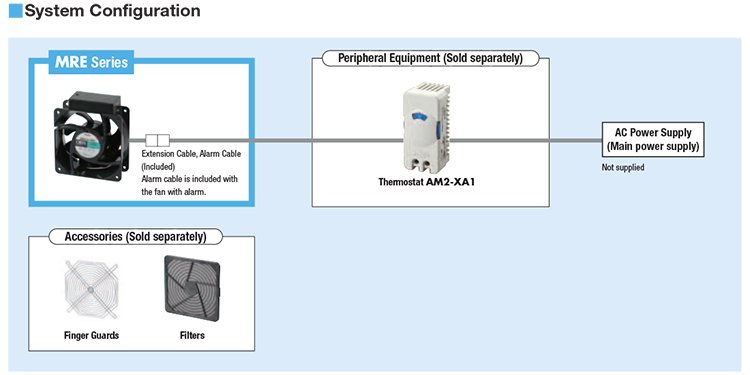

Thermostat Available for Energy Saving

Thermostats (sold separately) make it possible for fans to operate only when cooling is necessary. Thermostats provide energy-saving by automatically stopping fans for example, at night, when the amount of heat generation declines following the load rate's decline in equipment, or in winter, when the ambient temperature drops and forced cooling is not necessary.

Thermostat

Thermostats automatically perform ON/OFF fan control in accordance with the temperature fluctuation inside the equipment. It helps improve the equipment's "environmental" performance relative to energy savings, noise reduction, etc.

Type |

Item |

Centigrade (°C) |

Finger Guards

Finger guards prevent fingers or foreign objects from entering the fan. Finger guards are mounted to the fan frame using bolts.

Fan Size |

Finger Guard |

6.30 in. (160 mm) |

|

7.09 in. (180 mm) |

|

7.87 in. (200 mm) |

Filters

When using a fan to cool machinery, dust may accumulate inside the machinery after long periods of operation. Depending on the parts involved, this could cause a malfunction. These filters prevent dust from entering the device, keeping the air inside the machinery dust free.

Fan Size |

Filter |

6.30 in. (160 mm) |

|

7.09 in. (180 mm) |

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.