AC Centrifugal Fans / Blowers - MB Series S Type

AC Centrifugal Fans / Blowers - MB Series S Type

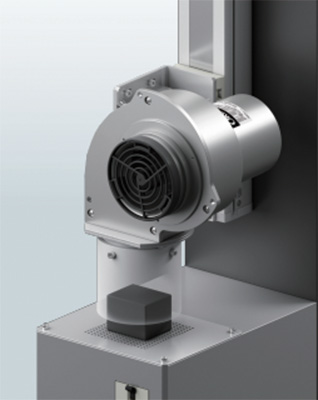

The MB Series S Type AC input centrifugal fans & blowers provide large static pressure and can produce directional air flow ideal for cooling, drying or forcing air through duct work. Available in 2 frame sizes 3.94 in. (100 mm) and 4.72 in. (120 mm) with a maximum air flow of 184 CFM (5.2 m3/min) and a maximum static pressure of 1.81 inH2O (450 Pa).

- Provides High Static Pressure and Directional Air Flow

- Single-Phase 100/110/115 VAC, Single-Phase 220/230 VAC or Three-Phase 220/230 VAC

- Supports Intake Air Temperatures of -10°C to +90°C (14°F to 194°F)

- Air Flow Can be Adjusted with a Damper (Sold Separately)

Centrifugal Blower Lineup

Impeller |

Power Supply | Max Air Flow |

Max Static Pressure |

||

Single-Phase 110/115 VAC |

88.3 CFM |

2.5 m3/min | 1.29 inH2O |

320 Pa | |

| Single-Phase 220/230 VAC | |||||

| Three-Phase 220/230 VAC | |||||

Single-Phase 110/115 VAC |

184 CFM |

5.2 m3/min | 1.81 inH2O |

450 Pa | |

Single-Phase 220/230 VAC |

|||||

Three-Phase 220/230 VAC |

|||||

MB Series S Type AC Centrifugal Fans / Blowers

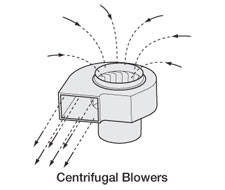

Centrifugal Fans / Blowers

Centrifugal blowers move air by means of the centrifugal force generated by rotating a cylindrical runner on which blades have been arranged. Centrifugal blowers have a small outlet, which concentrates air in a single direction and are therefore suitable for local cooling. They also create large static pressure, making them optimal for cooling equipment through which air cannot flow easily and for airflow through ducts.

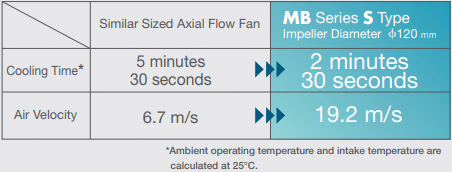

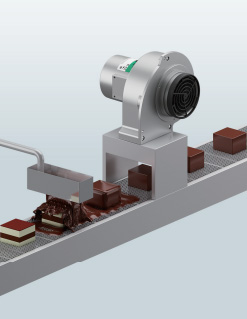

Cools Heated and Formed Workpieces as Quick as Possible

The high air velocity of the MB Series allows for high-speed cooling of heated and formed work pieces.

When cooling a 300°C iron plate (200 mm x 200 mm x 10 mm) to 100°C

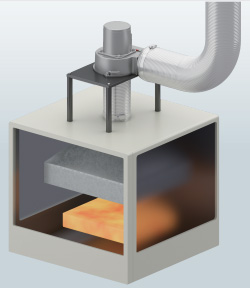

Air is Drawn Up Through the Ducts

(Supports Intake Air Temperatures of -10°C to +90°C)

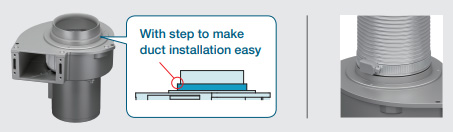

The MB Series' special design for use with ducts improves the ability to install with ducts.

Ducts can be installed directly using the step

Blows Liquids and Powders Off without Direct Contact

The air flow directionality of the MB Series can be used to blow liquids and powders. No need for humans or robots to touch the work piece.

Work Piece Alignment is Maintained During Transport

The suction power of the MB Series is useful in preventing lightweight or thin work pieces from scattering or becoming misaligned.

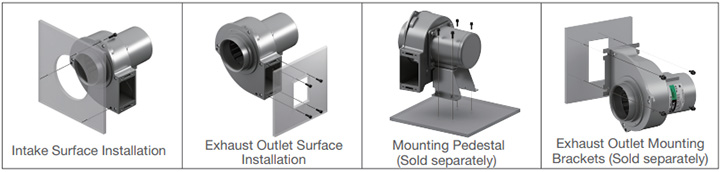

Installation Methods

The blower can be installed according to your needs using the mounting holes and mounting brackets. Accessories are also available to make installation convenient.

Air Flow Adjustment

Air flow can be adjusted manually by using an air flow adjustment damper (sold separately).

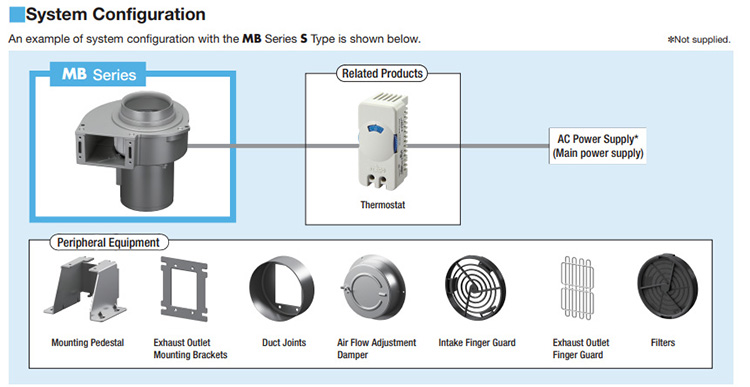

Thermostat

Thermostats automatically perform ON/OFF fan control in accordance with the temperature fluctuation inside the equipment. It helps improve the equipment's "environmental" performance relative to energy savings, noise reduction, etc.

Type |

Item |

Centigrade (°C) |

Mounting Pedestals

Mounting pedestals are used by assembling the mounting holes on the motor side. Capacitors can be fixed inside the mounting base, which helps to save space.

Fan Size |

Model |

| 3.94 in. (100 mm) | |

4.72 in. (120 mm) |

Finger Guards

Finger guards prevent fingers or foreign objects from entering the fan. Finger guards are mounted to the fan frame using bolts.

Fan Size |

Finger Guard |

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

Air Flow Adjustment Damper

The airflow adjustment damper is peripheral equipment that can be attached to the intake to allow for easy manual adjustment of the air flow. A numerical scale is engraved on the damper. This can be used as a marker when adjusting the air flow.

Fan Size |

Finger Guard |

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

Filters

When using a fan to cool machinery, dust may accumulate inside the machinery after long periods of operation. Depending on the parts involved, this could cause a malfunction. These filters prevent dust from entering the device, keeping the air inside the machinery dust free.

Fan Size |

Filter |

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

Exhaust Outlet Mounting Bracket

This is a mounting bracket for fixing on the blower’s exhaust outlet side.

Fan Size |

Model |

4.72 in. (120 mm) |

Duct Joint

Joint for connecting the centrifugal blower outlet and duct.

Fan Size |

Duct Joint |

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

Exhaust Outlet Finger Guard

This is a finger guard for attachment to the blower’s exhaust outlet. This prevents fingers and other objects from entering the exhaust outlet.

Fan Size |

Duct Joint |

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.