DC Centrifugal Fans / Blowers - MBD Series

DC Centrifugal Fans / Blowers - MBD Series

The MBD Series DC input centrifugal blowers provide large static pressure and can produce directional air flow ideal for cooling, drying or forcing air through duct work. Low Speed Alarm type fans are available.

Available in 3 frame sizes from 3.15 in. (80 mm) to 6.30 in (160 mm) with a maximum air flow of 106 CFM (3.0 m3/min) and a maximum static pressure of 1.49 inH2O (372 Pa).

- Provide High Static Pressure and Directional Air Flow

- 24 VDC or 48 VDC

- Low Speed Alarm types available

- Fan Kits available

Centrifugal Blowers Lineup

Impeller |

Power Supply | Options |

Max Air Flow* |

Max Static Pressure* |

||

24 VDC |

Low Speed Alarm Fan Kit |

51.2 CFM |

1.45 m3/min | 0.786 inH2O |

196 Pa | |

48 VDC |

Fan Kit |

|||||

24 VDC |

Low Speed Alarm Fan Kit |

68.8 CFM | 1.95 m3/min | 1.18 inH2O |

294 Pa | |

48 VDC |

Fan Kit |

|||||

24 VDC |

Low Speed Alarm Fan Kit |

106 CFM | 3.0 m3/min | 1.49 inH2O |

372 Pa | |

AC Centrifugal Fans / Blowers

Centrifugal Fans / Blowers

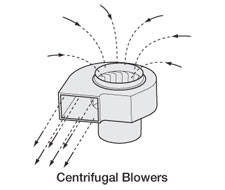

Centrifugal blowers move air by means of the centrifugal force generated by rotating a cylindrical runner on which blades have been arranged. Centrifugal blowers have a small outlet, which concentrates air in a single direction and are therefore suitable for local cooling. They also create large static pressure, making them optimal for cooling equipment through which air cannot flow easily and for airflow through ducts.

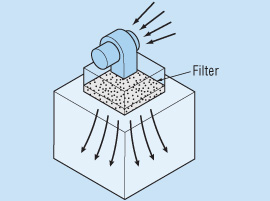

Cooling with High Static Pressure

The high static pressure of centrifugal blowers makes them suitable for cooling used together with thick filters that are subject to significant pressure losses.

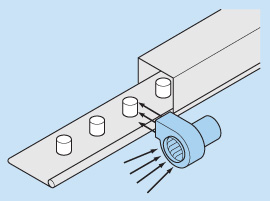

Air-Blow Cooling or Drying

Centrifugal blowers offering high static pressures are suitable for the air-blow cooling of work pieces following a heat treatment.

Low Speed Alarm Type

An alarm is output when the fan speed drops due to the service life of the fan or ingress of foreign objects. This makes it possible to order and replace the fan with a new one before it stops.

If multiple cooling fans are being used, it is possible to only replace the cooling fan with decreased cooling capacity. Even if the cooling capacity of the fan decreases, the effect on the equipment can be minimized.

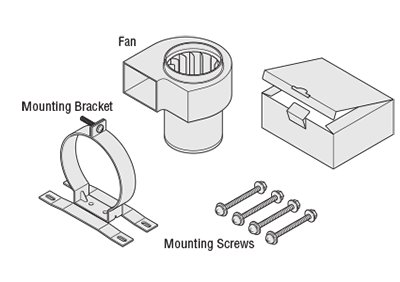

Fan Kits Available

Various accessories will help you improve the safety and utility of fans. We recommend our fan kits, which combine the fan and necessary accessories in a convenient package.

Example:

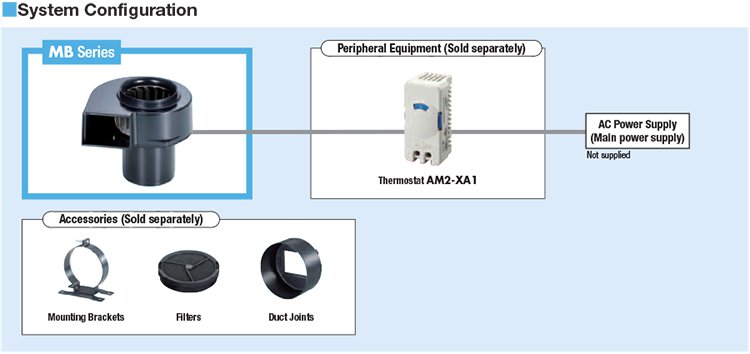

Thermostat Available for Energy Saving

Thermostats (sold separately) make it possible for fans to operate only when cooling is necessary. Thermostats provide energy-saving by automatically stopping fans for example, at night, when the amount of heat generation declines following the load rate's decline in equipment, or in winter, when the ambient temperature drops and forced cooling is not necessary.

Thermostat

Thermostats automatically perform ON/OFF fan control in accordance with the temperature fluctuation inside the equipment. It helps improve the equipment's "environmental" performance relative to energy savings, noise reduction, etc.

Type |

Item |

Centigrade (°C) |

Mounting Brackets

Mounting bracket using the motor case of the centrifugal blower.

Fan Size |

Model |

3.15 in. (80 mm) |

|

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

Finger Guards

Finger guards prevent fingers or foreign objects from entering the fan. Finger guards are mounted to the fan frame using bolts.

Fan Size |

Finger Guard |

3.15 in. (80 mm) |

|

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

Filters

When using a fan to cool machinery, dust may accumulate inside the machinery after long periods of operation. Depending on the parts involved, this could cause a malfunction. These filters prevent dust from entering the device, keeping the air inside the machinery dust free.

Fan Size |

Filter |

3.15 in. (80 mm) |

|

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

Duct Joint

Joint for connecting the centrifugal blower outlet and duct.

Fan Size |

Duct Joint |

3.15 in. (80 mm) |

|

3.94 in. (100 mm) |

|

4.72 in. (120 mm) |

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.