EAS Series Closed Loop Linear Slides

EAS Series Closed Loop AR Series Electric Linear Slides / Linear Actuators

The αSTEP EAS Series electric linear slides offer high performance, from low speed to high speed or with light loads or heavy loads, regardless of demanding operating conditions. These Electric linear slides featuring the AR Series stepper motors are quick and responsive and incorporates a ball screw and a THK-manufactured LM Guide™ as the guide. Being compact and rigid, this series is effective in supporting large transportable mass.

- Stroke Lengths from 50mm up to 500mm (contact your local sales office for stroke lengths up to 850mm)

- X-axis or Y-axis Table options

- Electromagnetic Brake available

- AC or DC Input

- Repetitive Positioning Accuracy = ±0.02 mm

- Requires AR Series Driver (sold separately)

Linear Slide Lineup

† For stroke lengths longer than 500 mm please contact your local sales office.

Type |

Power Input |

Options |

Max. Trans. Mass* (Horizontal) (kg) |

Max. Speed* |

Stroke † |

EAS4 |

6 mm or 12 mm Lead X-Axis or Y-Axis Table Electromagnetic Brake |

~15 or ~30 |

800 or 400 |

50 ~ 500 |

|

600 or 300 |

|||||

EAS4 |

Right or Left Motor Mount 6 mm or 12 mm Lead X-Axis or Y-Axis Table Electromagnetic Brake |

~15 or ~30 | 800 or 400 |

50 ~ 500 | |

600 or 300 |

|||||

EAS6 |

6 mm or 12 mm Lead X-Axis or Y-Axis Table Electromagnetic Brake |

~30 or ~60 |

800 or 400 |

50 ~ 500 |

|

600 or 300 |

|||||

EAS6 |

Right or Left Motor Mount 6 mm or 12 mm Lead X-Axis or Y-Axis Table Electromagnetic Brake |

~30 or ~60 | 800 or 400 |

50 ~ 500 | |

600 or 300 |

Repetitive Positioning Accuracy = ±0.02 mm

Dynamic Permissible Moment =

- EAS4 - MP: 16.3 N·m, MY: 4.8 N·m, MR: 15.0 N·m

- EAS6 - MP: 31.8 N·m, MY: 10.3 N·m, MR: 40.6 N·m

Static Permissible Moment =

- EAS4 - MP: 58.3 N·m, MY: 16.0 N·m, MR: 53.3 N·m

- EAS6 - MP: 86.0 N·m, MY: 34.0 N·m, MR: 110.0 N·m

*Max. Transportable Mass (Horizontal) = ~15 kg (12 mm Lead) or ~30 kg (6 mm Lead)

*Max. Speed = 800 or 600 mm/s (12 mm Lead) or 400 or 300 mm/s (6 mm Lead)

Linear Slides

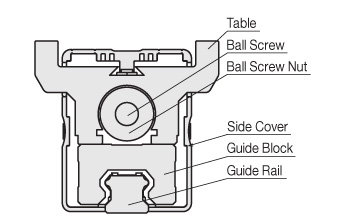

Compact & Powerful Linear Actuator

This linear actuator incorporates a ball screw and a THK-manufactured LM Guide™ as the guide. Since the high-accuracy LM Guide is directly installed in the enclosure base, these actuators are suitable for applications which require traveling parallelism. (Traveling parallelism 0.03 mm) Being compact and stiff, this series is effective in supporting large transportable mass.

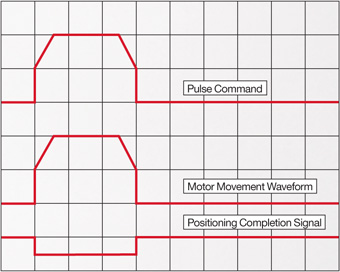

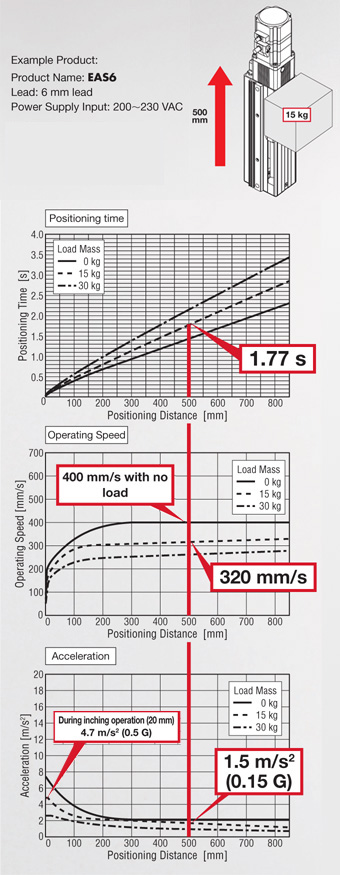

Quick & Responsive

The high response of the closed loop motor and drive system provides superior short-distance positioning.

Since the αSTEP AR Series operates synchronously with pulse commands and generates high torque with a compact body, it offers excellent acceleration performance and response

Capable of a Variety of Movements

Offering the ability from low speed to high speed or with light loads or heavy loads, these linear actuators are easier to use and offer high performance regardless of demanding operating conditions.

High-speed is possible with light loads or heavy loads, or even during inching operations.

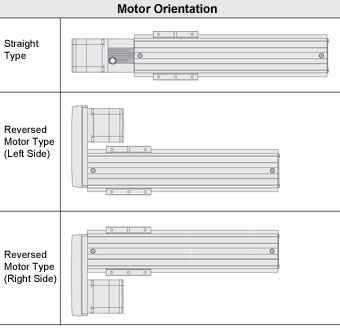

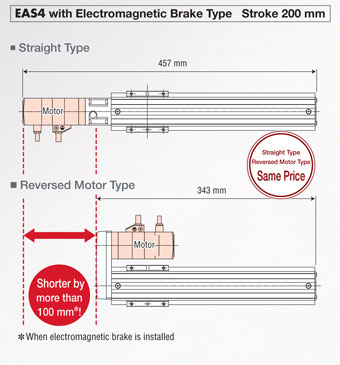

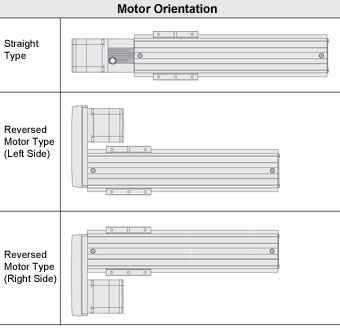

Direction of Motor Installation

Reversed Motor types are provided for all linear actuators. This contributes to a shorter overall length and space savings.

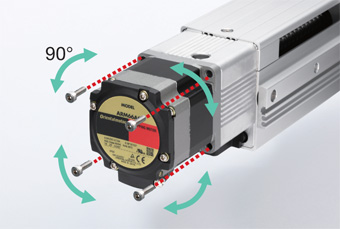

Cable Outlet Direction

Motor cable can be changed to any direction* by simply rotating

the motor. There is no need to leave space behind the motor since

the cable outlet is on one side of the motor, allowing for easy

connection and saving space.

*3 directions for Reversed Motor types

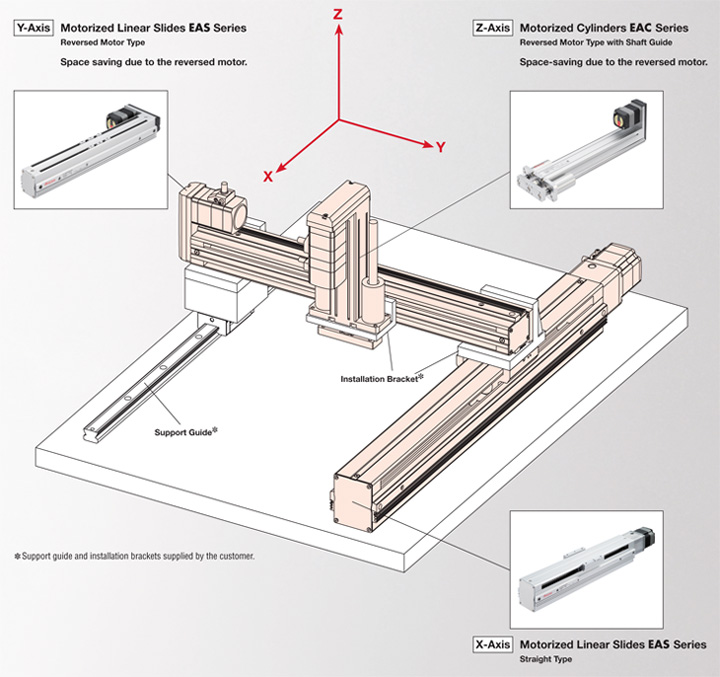

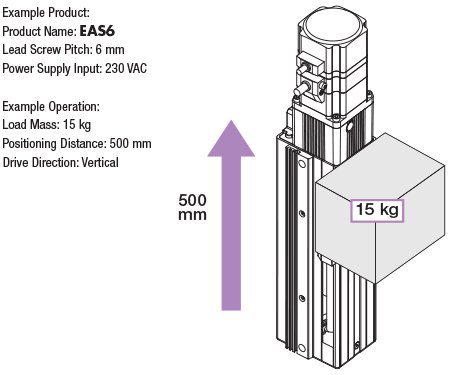

Application Example

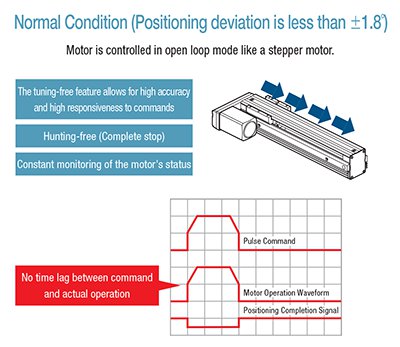

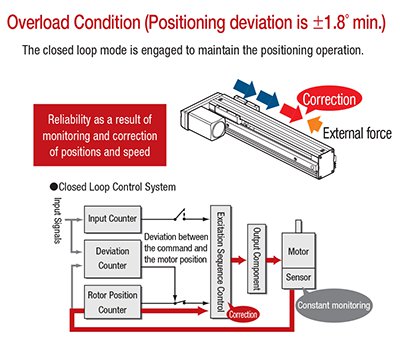

αSTEP Control System

Hybrid Control System

The hybrid control system constantly monitors the motors position allowing for the benefits of performance from "open loop" control while providing the assurance of "closed loop " performance.

Reversed Motor Type

Reversed Motor types are provided for all linear actuators. This contributes to a shorter overall length and space savings.

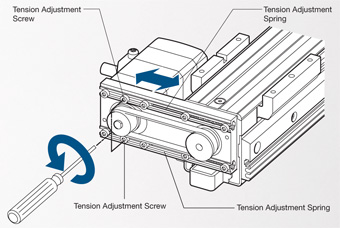

Simple Maintenance for Reversed Motor Type

Maintainability has been improved by using Oriental Motor's unique belt tension adjustment mechanism and through the standardization of maintenance parts based on the AR Series.

Thanks to Oriental Motor's unique belt tension adjustment mechanism, belt replacement is easy.

If the screw is loosened, the belt tension is adjusted to an appropriate value by the force of the spring.

X-Axis or Y-Axis Table

Choose either X-Axis or Y-Axis Table type to meet the needs of your application.

Electromagnetic Brake

Vertical operation is possible with electromagnetic brake. The load position can be held when the power is cut off. Since the work will not fall in case of power failure or disconnection, you can safely use equipment in which the work moves vertically.

AR Series AC Input Drivers

The αSTEP ARD (AC Input) Drivers offers superior high speed performance, low vibration and closed loop control. Available in a stored data (network) driver or pulse input driver. Advanced operation and function control is included through our MEXE02 software (free download). The ARD (AC Input) Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input or Built-in Controller (Network) Types

- Single-Phase 100-115, 200-240 VAC or Three-Phase 200-230 VAC

- For use with αSTEP AR Series Motors (AC Input)

AR Series DC Input Drivers

The αSTEP ARD-K (DC Input) Drivers offer 24/48 VDC input voltage, low vibration and closed loop control. Available in a stored data (network) driver or pulse input driver. Advanced operation and function control is included through our MEXE02 software (free download). The ARD-K (DC Input) Driver can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input or Built-in Controller (Network) Types

- 24/48 VDC

- For use with αSTEP AR Series Motors (DC Input)

Cables

These cables are used to connect or extend the distance between the motor and driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Sensor Set

The sensor set consists of three sets of a sensor, a sensor installation bracket and a flexible sensor cable with connector 6.6 ft. (2 m) and 1 shield plate. The screws needed for installation are also included.

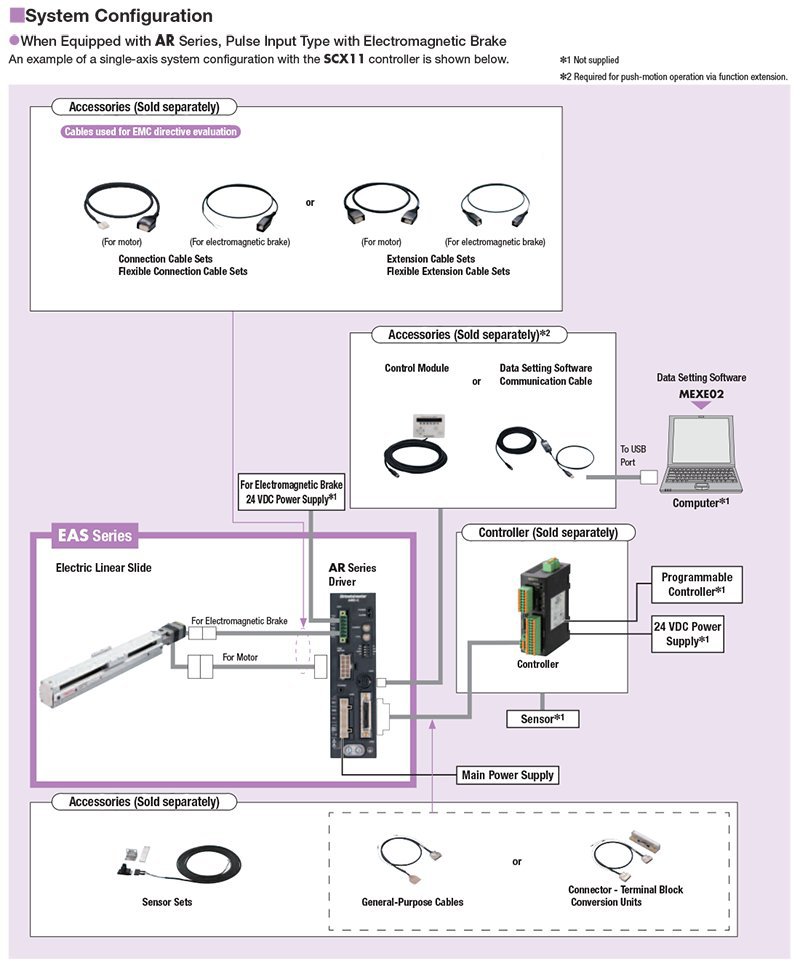

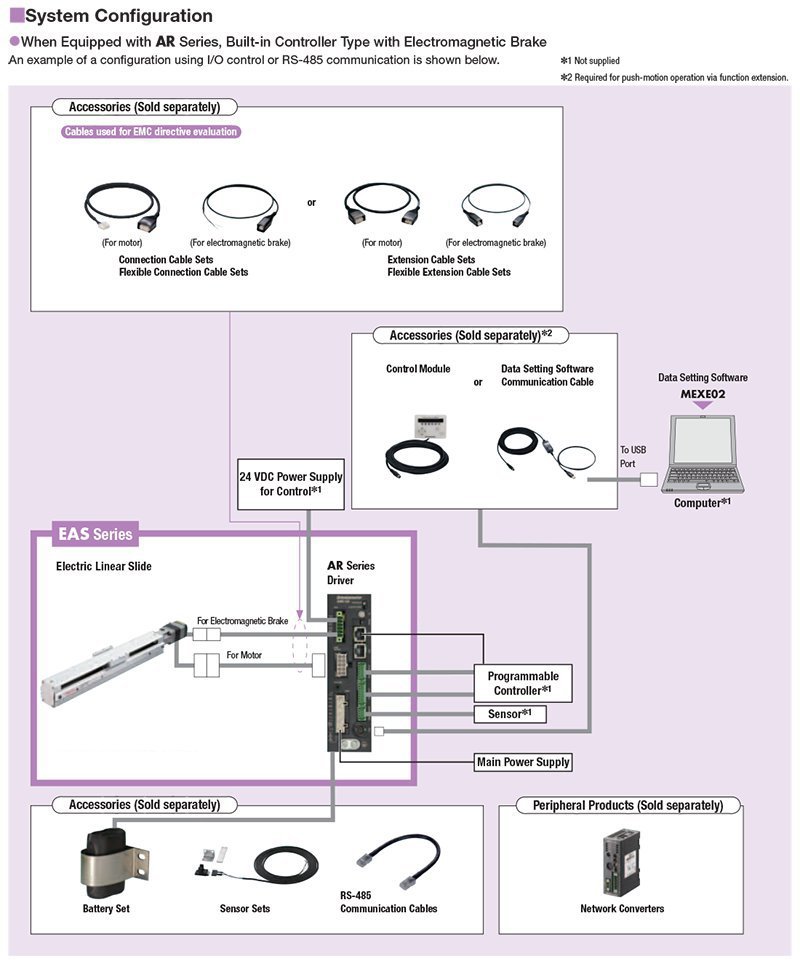

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.