Features and Functions of the EH Series Electric Gripper

Grippers are used as the end effectors of robots and automatic machines. They are divided into two types: “pneumatic grippers”, which use air pressure, and “electric grippers”, which use a motor. Pneumatic grippers are lightweight, low cost, and easy to drive, but fine-tuning the gripping force and speed is difficult. Electric grippers allow the user to freely set the gripping force, speed, and position to suit the load, and to reduce the shock, optimize the gripping force, and reduce the takt time. In addition, the position information of the motor makes it possible for the electric grippers to detect a load and confirm its dimensions. The EH Series electric grippers use a rack and pinion on the gripping mechanism and an AZ motor as the drive motor, giving this product the advantage of having gripping force that is easy to adjust. This document will explain the features and functions of the EH Series in addition to how to use it.

1. Introduction

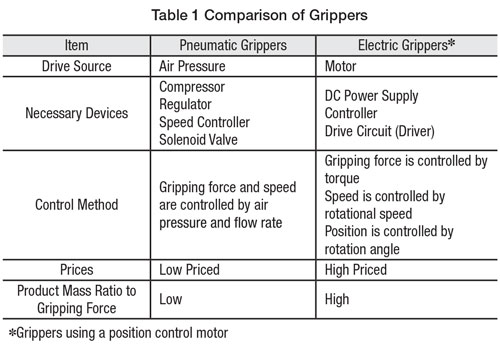

Grippers are actuators for gripping objects. They are mainly used as the end effectors of robots and automatic machines (See Fig. 1). Divided broadly by power source, there are two types of grippers: pneumatic grippers (also called air hands and air chucks), which use air pressure, and electric grippers, which use a motor. Table 1 shows a comparison of pneumatic grippers and electric grippers.

Pneumatic grippers are lightweight, low cost, easy to drive, and can be used for numerous work tasks involving gripping loads, such as pick and place operations. However, it is difficult to delicately grasp low-rigidity loads, and electric grippers are suitable for such applications. In addition, because electric grippers are driven by a position control motor, functions such as completion of workpiece gripping and dimensional confirmation can be performed without the use of additional sensors, which is effective in reducing work time and implementing automation. Electric grippers that operate on a DC power supply are also suitable for many mobile equipment units that operate on batteries and that are used in applications such as mobile robots and AGVs (Automated Guided Vehicles).

Oriental Motor has developed the EH Series (EH4-AZAKH) electric gripper that pairs a rack and pinion mechanism with a stepper motor (See Fig. 2). This document will explain the traits and functions of the EH Series, in addition to how to use it, while showing the measurement results on the actual equipment.

2. EH Series Electric Grippers

2.1 Structure

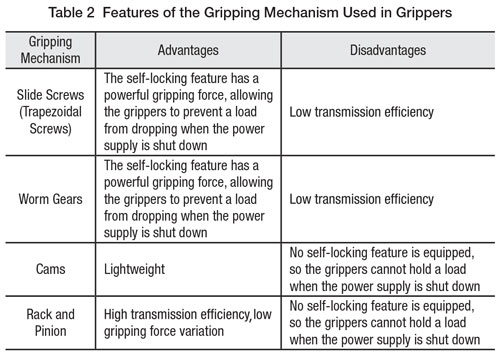

The gripping mechanism of the grippers uses cams, slide screws, worm gears, and a rack and pinion. Table 2 shows the features of each gripping mechanism. The EH Series features high transmission efficiency, and uses a rack and pinion with low gripping force variation.

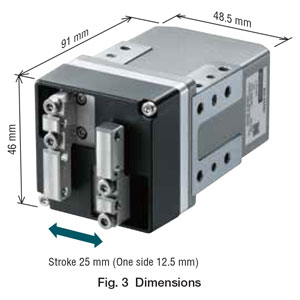

The EH4-AZAKH has a compact size, which was achieved by combining a rack and pinion with a 28 mm frame size motor (See Fig. 3).

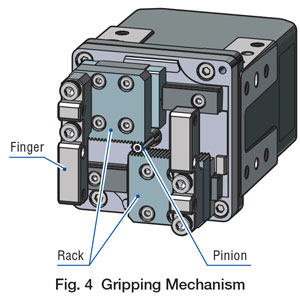

In addition, a long stroke distance has been attained by installing two racks and guides parallel to each other and installing a pinion between them in the center position (See Fig. 4).

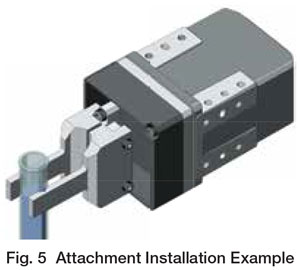

To grip a load, an attachment (hook) is prepared and installed to the end of the finger (See Fig. 5). When gripping loads of different shapes, such as in multi-product mixed production, the mechanism is able to grip objects whose dimensions differ by up to 25 mm without changing the attachment and gripper. This makes it possible to save on the labor and cost for changing tools, as well as reducing the installation space.

For the rack and pinion to have a long use life, grease is applied to the surface of the teeth. Testing has confirmed that the grippers operate properly 20 million times at maximum gripping force.

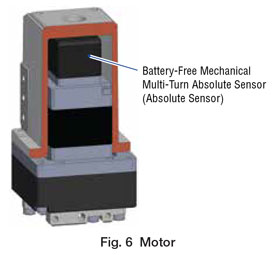

2.2. Motor

The motor uses the AZ Series (hereafter AZ motor), which is equipped with a battery-free mechanical multi-turn absolute sensor (See Fig. 6). Even if the power source is shut down, the Absolute Sensor mechanically retains position information, and therefore operation can resume without the device returning to the home position. Because there is no need for a return-to-home external switch, this cuts down on labor for such tasks as design, wiring, and adjustment.

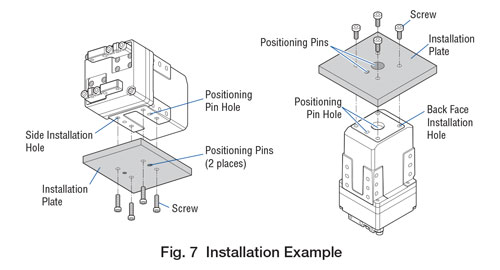

2.3. Installing Parts to Equipment

The EH Series can be installed in one of four directions: three side-facing installation directions and one back-facing installation direction (See Fig. 7). Due to this design, the user can change the direction of installation depending on the equipment. There are holes on each installation surface for inserting positioning pins.

3. Features

3.1. Gripping Force Control

To adjust the gripping force of pneumatic grippers, it is necessary to use a regulator (pressure-reducing valve) while checking a manometer, which does not make fine-tune adjustment an easy task. In addition, because there can be a loss of air pressure due to the length and inner diameter of the tubing that runs from the air compressor to the regulator, as well as due to the ambient temperature, it is necessary to make readjustments when these conditions change.

The EH Series allows the user to grip a load using “push motion operation”, which continuously applies pressure to the load. The user can fine-tune the gripping force by making adjustments to the maximum value of the motor current in 1% increments.

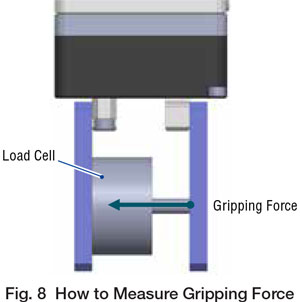

In addition, using a rack and pinion together with and a gripping mechanism with a low capacity loss allows the grippers to operate with stable gripping power, regardless of the operating ambient temperature. Furthermore, because the driver uses a constant current drive mode, the gripping force that is generated is not affected by the length of the connection cable. Fig. 8 shows the measurement method of gripping force, and figure 9 shows the measurement results when the operating ambient temperature and the length of the connection cable change. This shows that even for slight gripping force, such as approximately 6 N (running current value is 20%), the EH4-AZAKH is not effected by the operating ambient temperature or the length of the connection cable.

3.2. Speed Control

The pneumatic grippers use a speed controller (speed control valve) to change the amount of air and to adjust the opening and closing speed of the finger, but because the air shrinks and expands according to changes in pressure and temperature, speed stability is poor and it is difficult to make speed adjustments.

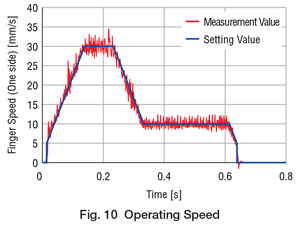

However, because the EH Series is motor driven, speed stability is better; and because the finger’s opening/closing speed, acceleration, and traveling amount can all be set easily using data, it is also possible to calculate the takt time. Fig. 10 is a comparison of the values for speed setting and measurement when the finger’s opening/closing speed is changed. The figure illustrates that operation in line with the settings is possible.

3.3. Reduction of Takt Time by Using Electric Grippers

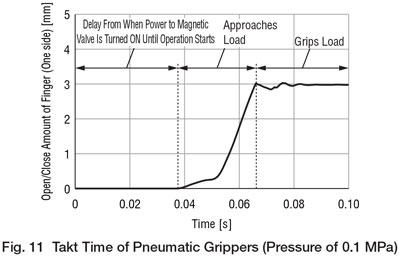

Changing the air pressure and flow rate adjusts the gripping force and speed of pneumatic grippers, but it is difficult to adjust these independently because the two functions affect each other mutually. While the grippers are operating, it is not easy to change the air flow rate and speed. In addition, when switching the air flow supply from the regulator to the grippers by opening and closing an electromagnetic valve, a delay of between 10 ms and several tens of milliseconds occurs from the time the electromagnetic valve is turned on to the time the finger starts to move. Therefore, the opening and closing speed of the finger is fast, but the time it takes for the grippers to completely grip a load becomes longer. Fig. 11 shows the takt time measured for pneumatic grippers that have a maximum gripping force equivalent to the EH4-AZAKH.

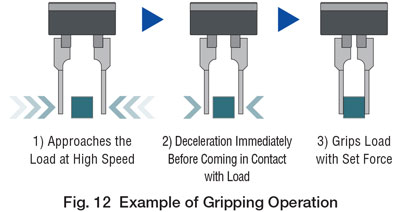

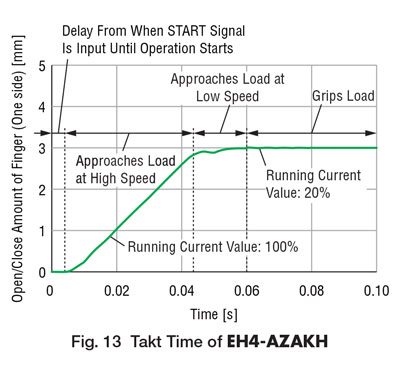

The EH Series can independently control gripping force, speed, and positioning. It is possible to use a combination of high-speed approach positioning operation, which positions the finger to the target position, and push-motion operation, which grips loads at low speeds (See Fig. 12). This makes operation with a short takt time possible.

In addition, the delay from the time the START signal that executes the operation is input until the device starts to move is very short, and a shorter takt time than that for pneumatic grippers can be achieved. Fig. 13 shows the measurement result of the takt time for EH4-AZAKH.

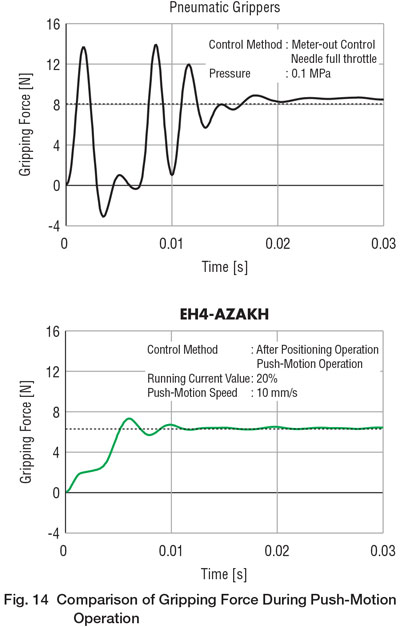

Employing slow speed operation immediately before gripping a load allows the EH Series to control the amount of shock applied to the load. Fig. 14 compares pneumatic grippers and the EH Series' change in gripping force the moment the grippers come in contact with a load. The moment gripping begins with the EH Series, the amount of gripping overshoot and undershoot is suppressed and less than the pneumatic grippers, indicating that the shock applied to the load is small.

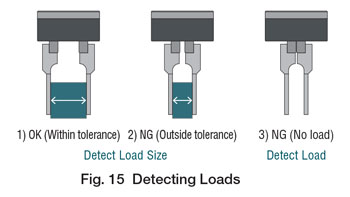

3.4. Outputting Gripper Position Information

Pneumatic grippers do not have a built-in sensor, so an external switch is required to check the start of operation and the completion of gripping. The EH Series does not require an external switch because the positioning information can be checked from the motor’s Absolute Sensor. To allow the system to determine that a load has been gripped, the TLC output signal (which is output when gripping force reaches the set value) is output; to allow the system to detect a load and its size, the AREA output signal (which is output when the finger is in the area specified in the settings) is output (See Fig. 15).

4. How to Use the Device

This section will explain how to execute “load dimensions measurement” using the functions and characteristics of the EH Series, and how to generate “minute gripping force”. The conditions under which this feature can be used are limited, but it can be used to reduce the labor for checking dimensions and for such things as gripping low rigidity loads that deform easily.

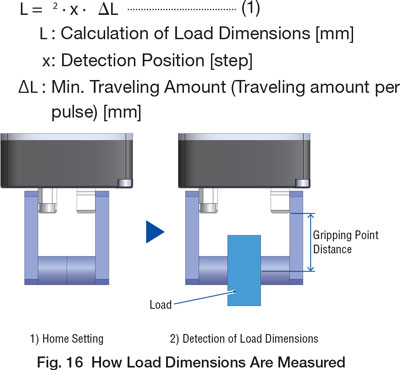

4.1. Measuring the Dimensions of a Gripped Load

Using the positioning information of the Absolute Sensor, the EH Series can simultaneously grip a load and measure its dimensions. Fig. 16 shows an example of how the dimensions of a load are measured. First, the gripper executes gripping with no load present, and the home setting is configured based on the input of the CLR signal (which stops operation at the current detection position) and the P-PRESET signal (which sets the current position to 0). Next, the grippers grip the load. When this occurs, the dimensions of the load are detected based on the positioning output from the driver (Formula [1]).

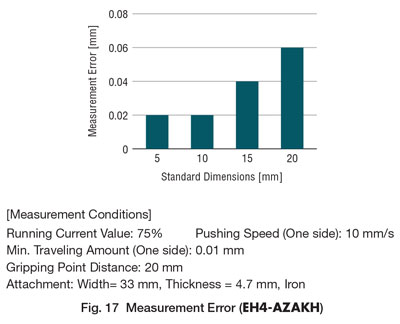

When determining whether a load whose dimensions differ significantly from the settings is acceptable or not, the user can use the home setting without using a master load. However, because a measurement error may occur (See Fig. 17) due to either the attachment or the load becoming deformed as a result of the impact of the gripping force, it may be necessary to make improvements.

The following measures are effective at reducing measurement error.

a) Configure the home setting using a master load with dimensions similar to the load

b) Adjust the gripping force to match the rigidity of the load

c) Increase the durability of the attachment

d) Shorten the gripping point distance

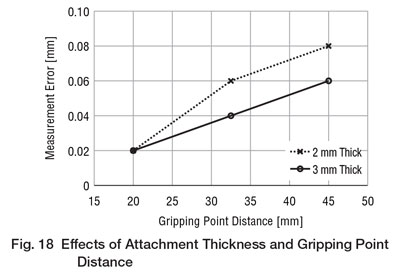

Measure a) improves the measurement accuracy, and measures b), c), and d) reduce the impact of attachment deformity. When using measure a) to configure the home setting, the value calculated from Formula (1) is the difference in size between the master load and the actual load. Fig. 18 shows the measurement error when the thickness of the attachment and the gripping point distance are changed. The thicker the attachment and the shorter the gripping point distance, the more rigidthe attachment will be, and smaller the measurement error will be.

4.2. How a Load is Gripped Using Positioning Operation

Thus far, this document has explained push-motion operation that is possible with a constant force regardless of any variation in the dimensions of the load; however, what follows will explain positioning operation using the angle-torque characteristics of a stepper motor as a way of gripping more fragile loads.

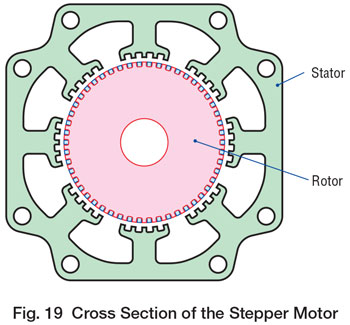

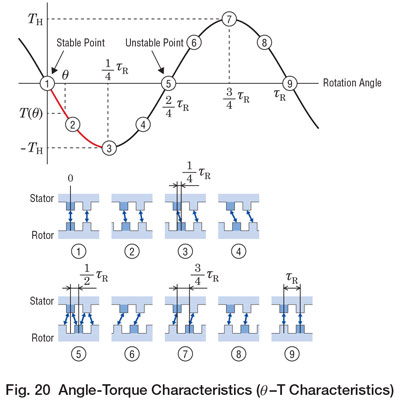

The stator and rotor of the stepper motor are each equipped with small teeth (See Fig. 19). When the coil on the main pole of the stator is excited, the small teeth on that main pole and the small teeth on the rotor attract each other and stop so that they are opposite each other. When torque is applied to the shaft of a standstill motor, it allows the shaft to rotate slightly. When this occurs, the relationship shown between the applied torque and the rotation angle of the shaft is called the angle-torque characteristics ( – T characteristics)(1) (See Fig. 20). The gripping force due to the angle-torque characteristics of the stepper motor change according to the closing width of the finger. When using a positioning operation to grip a load using minute force, torques (1) to (3) shown in Fig. 20 are used.

For the EH Series, gripping force is generated by using positioning operation to close the attachment slightly tighter than the dimensions of the load.

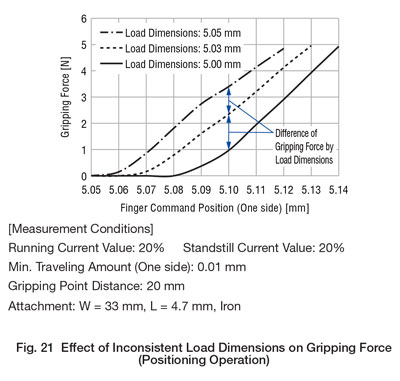

The gripping force due to the positioning operation is determined by the running current value and the closing width of the finger after it contacts the load. If the variation of the load dimensions is small, it is possible to apply a minute gripping force of less than 6 N, which is difficult to achieve using push-motion operation. However, because the variation of the load dimensions impacts the rotation angle, this method can be used only if the variation in dimensions is small (See Fig. 21).

5. Summary

By controlling the gripping force and speed using data settings, the EH Series suppresses the shock applied to the load while making operation with a short takt time possible. In addition, using the functions and characteristics of the AZ motor makes it possible to measure the dimensions of the load and to grip the load using minute force.

We believe that the characteristics and functions of the EH Series that were introduced in this document can resolve the issues our customers experience. Going forward, we plan to add products to our lineup that are smaller, more lightweight, and that meet the demand for minute gripping force.