DGII Series Closed Loop Hollow Rotary Actuators

DGII Series Closed Loop AR Series Hollow Rotary Actuators

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an αSTEP closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

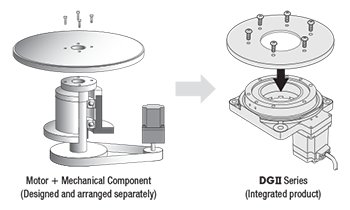

- Integrated actuator and stepper motor makes design easier

- Large-diameter hollow output table

- Stepper motor provides excellent performance

- Agile responsiveness

- Stability at low speeds

- Tuning-free

- AC or DC Input

- Requires AR Series Driver (sold separately)

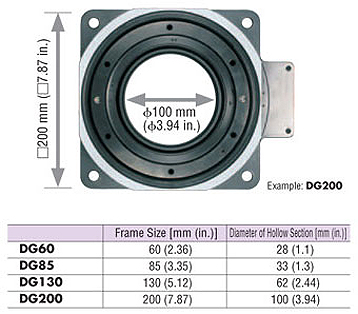

Rotary Actuator Lineup

Frame Size |

Power Input |

Options |

Permissible |

Permissible Speed |

Permissible Moment Load |

||

60 mm (2.36 in.) Rotary Actuator |

Single or Double Shaft |

0.9 N·m |

7.9 lb-in |

200 r/min |

2 N·m |

17.7 lb-in |

|

85 mm (3.35 in.) |

Single or Double Shaft |

2.8 N·m |

24 lb-in |

200 r/min |

10 N·m |

88 lb-in |

|

130 mm (5.12 in.) Rotary Actuator |

Single or Double Shaft Electromagnetic Brake |

12 N·m |

106 lb-in |

200 r/min |

50 N·m |

440 lb-in |

|

200 mm (7.87 in.) |

Single or Double Shaft Electromagnetic Brake |

50 N·m |

440 lb-in |

110 r/min |

100 N·m |

880 lb-in |

|

Repetitive Positioning Accuracy = ±15 arcsec (±0.004°)

Lost Motion = 2 arcmin (0.033°)

Hollow Rotary Actuators

High Positioning Accuracy

- Non-Backlash

- Repetitive Positioning Accuracy ±15 sec

- Lost Motion 2 arc minutes

Note: The repetitive positioning accuracy is measured at a constant temperature (normal temperature) under a constant load.

Large-Diameter, Hollow Output Table Makes Simple Wiring and Piping Possible

The large diameter hollow hole (through-hole) helps reduce the complexity of wiring and piping, thus simplifying your equipment design.

Contributes to Easier Equipment Design

The gear-reduction mechanism employs precision gears along with a proprietary adjustment mechanism that eliminates backlash. The repetitive positioning accuracy from a single direction is ±15 sec., while lost motion in a positioning operation from two directions is 2 arc minutes. These characteristics make the DGII series the ideal choice for applications in which accurate positioning is a must.

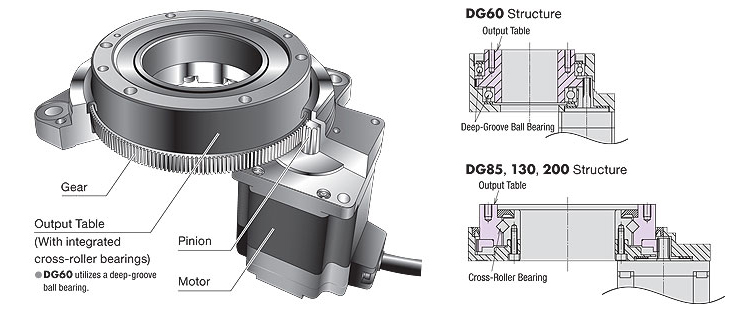

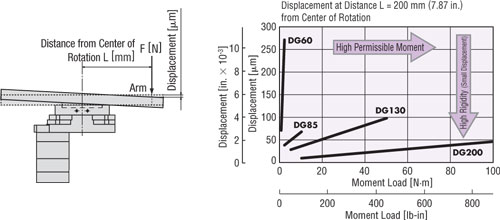

High Power and Rigidity

The hollow output table is integrated with a high rigidity crossroller bearing*. The structure improves permissible thrust load and moment load while maintaining high torque.

*Excludes the DG60

The output table uses deep-groove ball bearings (two pieces) for the 2.36 in. (60 mm) frame size type, and a cross-roller bearing for the 3.35 in. (85 mm), 5.12 in. (130 mm) and 7.87 in. (200 mm) frame size types. As the frame size increases, the permissible moment load also increases but the displacement caused by the moment load decreases.

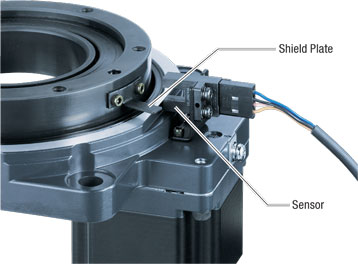

"Home Sensor Set" is Available as an Accessory

Since the sensor set comes with all the parts required for the return-to-home operation, less time is spent designing, fabricating and procuring parts related to sensor installation.

DG130 Sensor Installation Example

Direct Coupling for Higher Reliability

Equipment tables and arms can be installed directly on the output table. This saves you the hassle and cost of designing an installation mechanism, arranging necessary parts, adjusting the belt tension, etc. when mechanical parts such as belt and pulley are used for installation.

High Reliability Plus High Efficiency αSTEP AR Series Motors

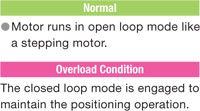

High Efficiency and Energy Saving

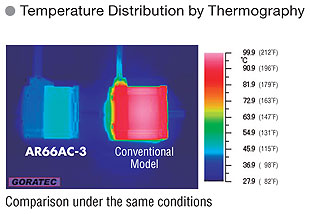

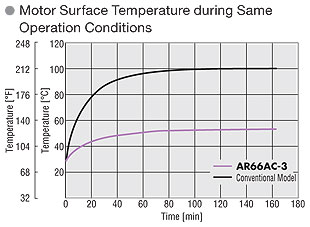

A closed loop αSTEP AR Series stepper motor and driver package has been adopted as the motor. This creates a more efficient and energy saving product compared with conventional models.

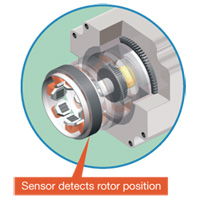

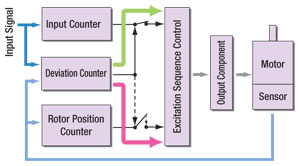

The αSTEP AR Series uses Oriental Motor's closed loop control to maintain positioning operation even during abrupt load fluctuations and accelerations. The rotor position detection sensor monitors the rotation. When an overload condition is detected, the AR Series will instantaneously regain control using the closed loop mode. When an overload condition continues, the αSTEP AR Series will output an alarm signal, thereby providing reliability equal to that of a servo motor.

Adoption of a Rotor Position Detection Sensor (Resolver) -

Because the sensor is compact and slim, the overall length of the motor has been reduced.

Performance such as heat resistance and vibration resistance is improved over regular optical encoders.

Because an encoder cable is not necessary, the motor and driver can be connected with just 1 cable.

Lower Heat Generation

Heat generation by the motor has been significantly reduced through higher efficiency.

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

Operates synchronously with commands using open loop control during normal conditions. In an overload condition, changes immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, an END signal is output. This ensures the same level of reliability achieved by an advanced closed loop system or a servo motor.

Power Consumption: 66% Less* Than Conventional Model

AR Series AC Input Drivers

The αSTEP ARD (AC Input) Drivers offers superior high speed performance, low vibration and closed loop control. Available in a stored data (network) driver or pulse input driver. Advanced operation and function control is included through our MEXE02 software (free download). The ARD (AC Input) Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input or Built-in Controller (Network) Types

- Single-Phase 100-115, 200-240 VAC or Three-Phase 200-230 VAC

- For use with αSTEP AR Series Motors (AC Input)

AR Series DC Input Drivers

The αSTEP ARD-K (DC Input) Drivers offer 24/48 VDC input voltage, low vibration and closed loop control. Available in a stored data (network) driver or pulse input driver. Advanced operation and function control is included through our MEXE02 software (free download). The ARD-K (DC Input) Driver can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input or Built-in Controller (Network) Types

- 24/48 VDC

- For use with αSTEP AR Series Motors (DC Input)

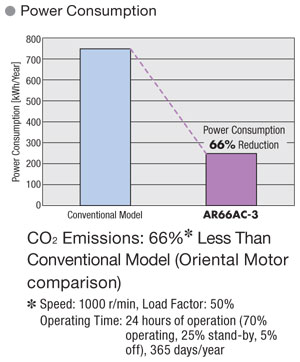

Cables

These cables are used to connect or extend the distance between the motor and driver.

Required (sold separately).

Use a flexible motor cable if the motor is installed on a moving part or its cable will be flexed.

Home Sensor Set

A home-sensor set, which consists of a photomicro sensor, connector with cable, sensor mounting bracket, shielding plate and mounting screws, is provided to facilitate easy return to home operation.

Available in NPN or PNP sensor output.

Item |

Sensor |

Applicable |

NPN |

DG60 |

|

PNP |

||

NPN |

DG85 |

|

PNP |

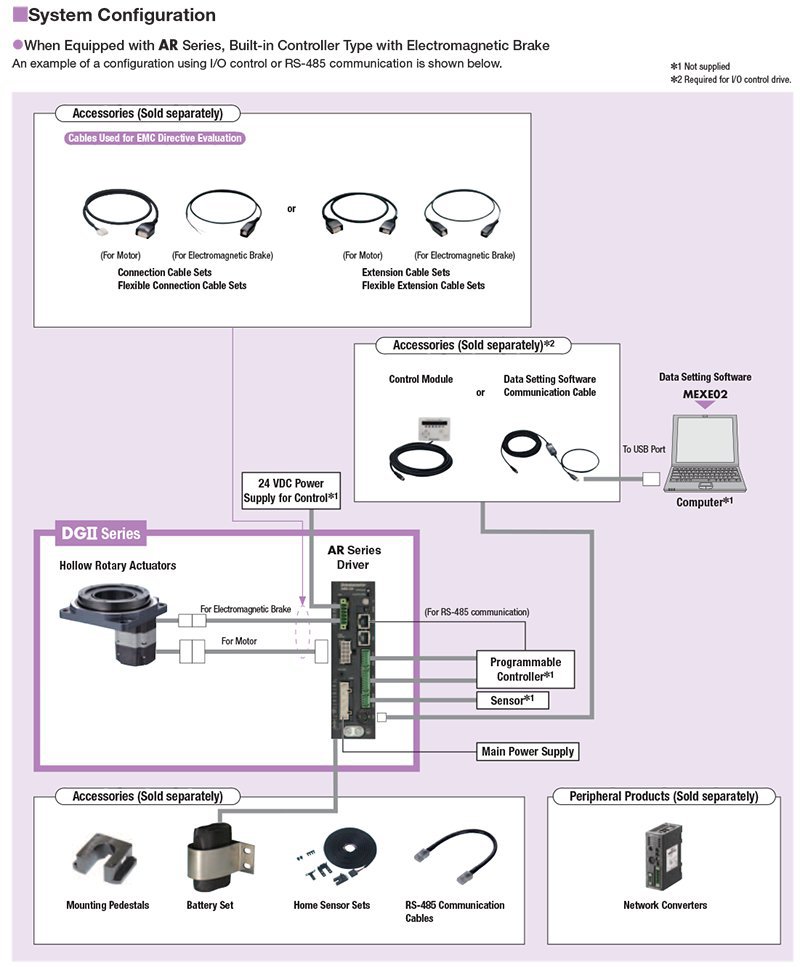

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.