SCX11 Single-Axis Controller

SCX11 Single-Axis Universal Controller

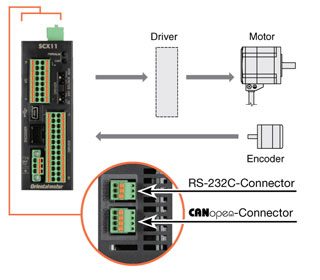

The SCX11 is a highly-functional and sophisticated controller equipped with program editing and execution functions. Use the SCX11 as a stored program controller to connect to any of Oriental Motor's standard pulse input drivers. The SCX11 is also able to control the motor via serial communications such as USB, RS-232C and CANopen. Accepts encoder inputs.

- 24 VDC Input

Included with SCX11:

- Universal Controller (SCX11)

- CD-ROM (Immediate Motion Creator for SCX Series, Operating Manual, CANopen, EDS files)

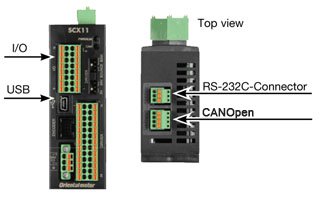

- RS-232C connector (3 pins)

- CANopen connector (4 pins)

- Power Connector (3 pins)

- Encoder connector housing / contact (8 pins)

- Start up manual

Controller Lineup

Controller |

Number of Control Axis |

Serial Communication |

Daisy Chain |

Encoder Feedback |

Maximum Pulse Frequency |

Single Axis |

RS-232C |

Yes |

Yes |

1.24 MHz |

Universal Controller

100 Sequence Programs can be Stored

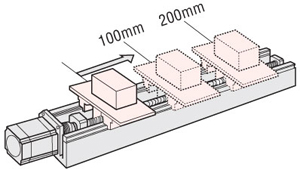

The SCX11 can store up to 100 programs and execute various operations, from simple movements like "repeated positioning operation" to complicated controls like "operation by calculating the value based on external inputs".

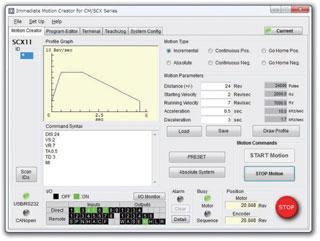

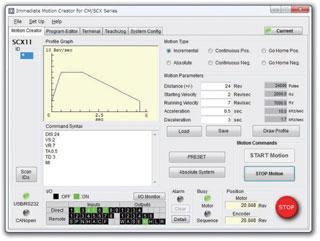

Easy Operation

The convenient and easy-to-use PC software, "Immediate Motion Creator for CM/SCX Series", is provided with the SCX11. Easily start an operation with the click of a button or start key by setting the travel amount and speed. The GUI allows for easy program creation by selecting commands from the commands list. Other functions available include; real time monitor for the teaching position, current position and I/O status, system parameter setting, oscilloscope function and I/O assignment.

Intelligent Setting

Program data for speed and travel amounts by setting the "User Unit" parameter. Data can be programmed in units such as "mm", "inch" and "revolution".

External Encoder Input

The SCX11 has a function for external encoder inputs which enables continuous monitoring of the feedback position and position error. Line driver, open collector and TTL inputs are compatible.

USB Port as Standard Equipment

The SCX11 has a mini USB port on the front panel which can directly connect to a PC through a commercially available mini USB cable. No special cable or converter is required.

Various Interfaces for Operation

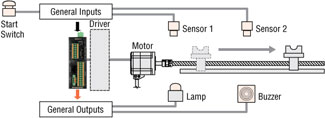

1. Stand-Alone Operation Using Sensors and Switches

The SCX11 can operate as a stand-alone controller, without a PC or programmable controller by utilizing 9 general inputs and 4 general outputs to select the desired sequences.

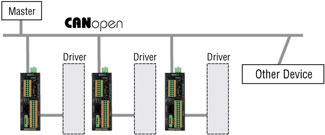

2. Direct Command Operation via CANopen

The SCX11 has a standard built-in interface for CANopen.

*CANopen for the SCX11 is certified by CiA (CAN in Automation).

3. Operation Using a PC

The SCX11 can connect to a PC via RS-232C or USB. The SCX11

can also be connected via an RS-232C daisy chain connection for

multi-axis control with another SCX11 or other products such as the

ASX Series all-in-one closed loop Alphastep motor.

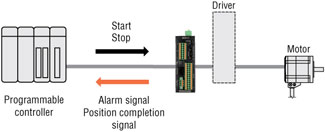

4. Operation Using a Programmable Controller

The SCX11 can communicate a wide variety of signals via I/O to a

programmable controller. Serial communications is also available, if

the programmable controller has a USB or RS-232C interface built-in.

Two Types of Operations

1. Executing Sequence Operation [Stored Program Function]

This function is available for conditional branching using general-purpose I/O, wait processes using internal timers and other operations based on sequence control including setting the positioning and speed data. The SCX11 can store up to 100 different programs that can be selected and executed via USB, RS-232C, CANopen and I/O port.

[ Example program ]

S e q 1

[ 1 ] V S 1 ; Starting Velocity

[ 2 ] V R 9 ; Running Velocity

[ 3 ] T A 1 ; Acceleration Time

[ 4 ] T D 2 ; Deceleration Time

[ 5 ] D I S 2 ; Incremental Motion Distance

[ 6 ] L O O P 3 ; Begin Counted LOOP Block

[ 7 ] M I ; Move Incremental Distance

[ 8 ] M E N D ; Wait for Motion End

[ 9 ] W A I T 1 ; Wait for Specified Time

[ 1 0 ] E N D L ; End of LOOP Block

[ 1 1 ] M A 0 ; Move to Absolute Position

[ 1 2 ] M E N D ; Wait for Motion End

[ 1 3 ] E N D ; End Sequence

*You can set the speed and travel amount as the unit of your actual motion such as "mm", "inch" and "revolution".

2. Direct Command Operation

Operate a motor directly by sending commands via the serial

port (USB, RS-232C, CANopen) from a PC or programmable

controller. This function is suitable for applications where positioning

data is updated frequently or managed all at once by the PC or

programmable controller.

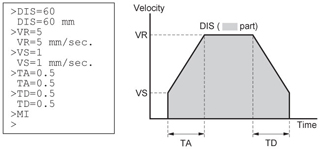

[ Example Commands ]

D I S ; Incremental Motion Distance

V R ; Running Velocity

V S ; Starting Velocity

T A ; Acceleration Time

T D ; Deceleration Time

M I ; Move Incremental Distance

M A ; Move to Absolute Position

M C P ; Move Continuously, Positive

M C N ; Move Continuously, Negative

M G H P ; Seek Mechanical Home Position

A L M C L R ; Clear Alarm Condition

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.