Overcoming Rotation Vibration, CVD Series 2-Phase Bipolar Stepper Motor Driver

Easily Minimize Vibration with Affordable Advanced Technology

Ideally, stepper motors should operate smoothly without vibration throughout all speed ranges. In reality, they run with some vibration at low, mid, or high speeds, causing unwanted noise. This type of vibration is called "rotation vibration" and developing the suppression system for the rotation vibration is a major challenge. To overcome this, it is common to microstep a stepper motor, into many smaller steps. However, with today's technology, microstepping alone is not enough. Not all stepper motor drivers or chips manage rotation vibration the same way. This technical paper will explain the advantages of the CVD Series 2-Phase Bipolar stepper motor driver technology.

Improvement of Current Control

· Applying the individual-phase current detecting method by the use of the latest microprocessor technology with advanced algorithms

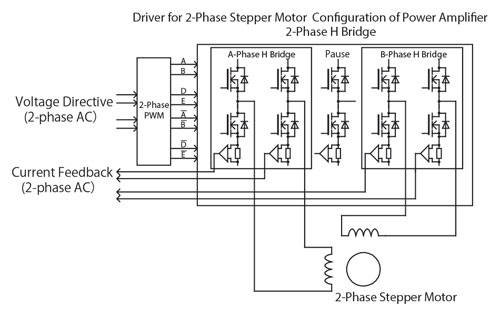

Controlling the motor means controlling the current that runs through the motor windings. If the current running through the motor windings can be controlled, it is possible to operate the motor more smoothly. To do so, the manner in which the motor winding current is detected becomes important.

Historically, one of the advantages of 5-Phase stepper motor technology is that circuits use an all-phase current detecting method that simultaneously detects the currents from all 5 motor cables (wire) connected to the motor. Since this method required only one detecting circuit, the circuit was simple. However, this method cannot detect the back-flow current that does not go through the detecting circuit. Because of this, current control becomes unstable, resulting in extra driver design steps to control vibration.

Oriental Motor's CVD driver uses the individual-phase current detecting method to improve current control, which detects 5 different currents separately or in the case of the 2-Phase CVD driver, 4 different current controls (Refer to Figure 1), using the latest microprocessor technology with advanced algorithms programmed in.

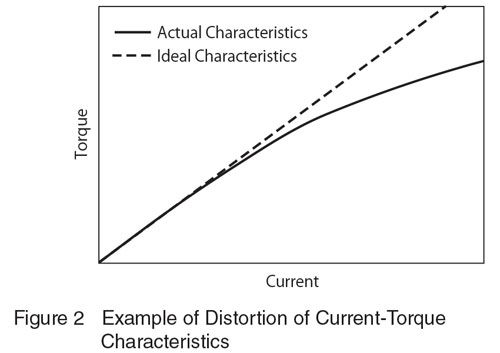

Maximum Torque with Current Correction

· Maximize motor torque output by utilizing the electromagnetic current characteristics of the motor

The motor output torque is proportional to the current in the range where the current of a motor winding matches the proportional torque output. As the current gets larger, meaning more than the rated current is applied to the windings, due to the magnetic saturation phenomenon caused by armature reaction of the magnetic flux, the relationship of the current and torque gradually strays from its proportional relation (Refer to Figure 2). In order to increase the output torque of a motor, it is necessary to effectively utilize the range where straying of the proportional relation occurs.

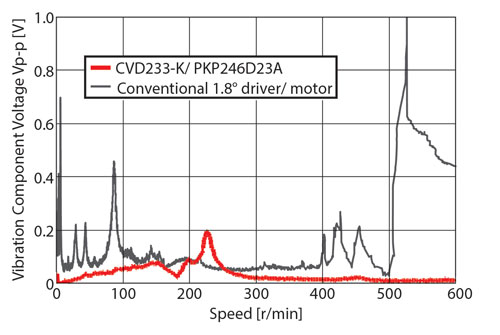

Advanced Microstepping

· Smooth Drive, using the latest microprocessor allows for microstepping in all speed ranges

Because stepper motors run and stop at each step angle, they are capable of high accuracy position control. However, because the rotor speed changes when rotating at each basic step angle, this may become the cause of vibration or noise. Microstepping has been implemented to suppress this type of vibration. Microstepping is a technology that divides the basic step angle of the motor by controlling the current flowing through the motor winding. By reducing the step angle, speed change is minimized when moving one step forward, which makes it possible to achieve low vibration.

The CVD, in addition to microstepping offers Smooth Drive technology, the most advanced microstepping function, without the need for increased pulses sent to the driver. The CVD with Smooth Drive ON automatically microsteps up to a maximum of 2048 steps (0.0008°) per full step of the motor (1.8°). Most microstep drivers offer resolution up to 51,200 microsteps per revolution (0.007°). With Smooth Drive on, this significantly improves overall performance across all speed ranges, not just the lower speed range (Figure 3), drastically reducing vibration that can cause step errors. This allows for a wider design window of motor speed to performance results.

Minimizing Torque Ripple

· Correcting the sinusoidal current supplied to the motor

Fluctuation of output torque when changing excitation phases is called torque ripple. Theoretically, torque ripple does not occur by changing the torque occurred at each phase to a sinusoidal wave. If the relationship of the motor current and generated torque is in a linear form, torque ripple would not occur by changing the current at each phase to a sinusoidal wave. However, the relationship of the motor current and generated torque is NOT in a linear form. Therefore, when changing the current at each phase to the sinusoidal wave, torque distortion occurs where the current value is large, which causes vibration. In short, dealing with high output torque and low vibration at the same time requires additional control mechanism.

To solve this issue, the CVD driver appropriately corrects the phase of the sinusoidal current supplied to the motor. This has created an effect to correct the distortion of current-torque characteristics, enabling to handle low vibration and high output torque at the same time. In addition, this has improved stop position accuracy.

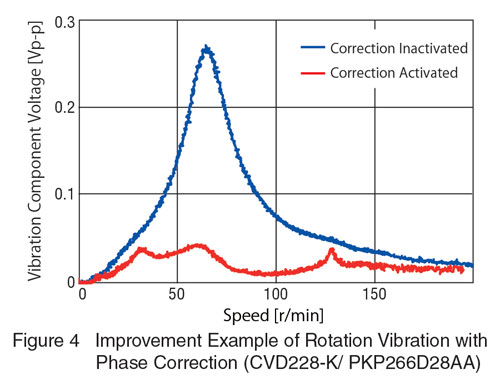

Figure 4 shows how much rotation vibration characteristics are improved with the phase correction. The peak value of vibration is dramatically improved by activating the phase correction.

An optimal value of phase correction changes depending on the motor magnetic property. For this reason, an optimal correction amount is set up for each driver that is combined with a motor.

After considering the motor magnetic property, current control is conducted, while bringing out high performance - This is one of the strengths of Oriental Motor where developing both motors and drivers is done.