Fuji Electric FRENIC-Mini (C2) Inverters / VFD

Fuji Electric FRENIC-Mini (C2) Inverters / VFD

With its high functionality, compact design, simple operation, built-in network connectivity and global compatibility, the new FRENIC-Mini (C2) elevates the performance of a wide range of devices and equipment--including conveyors, fans, pumps, centrifugal separators, and food processing machines--to give you the system integration, energy efficiency, reduced labor, and lower overall costs you're looking for.

With standard functions like high starting torque, network compatible, optimum energy savings, the FRENIC Mini (C2) is ideal for OEM's and panel builders. The optional NEMA/UL Type 1 kit allows the FRENIC-Mini (C2) to also be easily applied to stand alone applications.

- For use with 1/8 HP up to 3 HP Three-Phase Motors

- Single-Phase 115 VAC or 230 VAC input, Three-Phase 230 VAC or Three-Phase 460 VAC input.

Inverter / VFD Lineup

Inverter |

Power Supply Input |

Rated Output Voltage |

Rated Output Current |

Single-Phase 100 ~ 120 VAC |

Three-Phase 200 ~ 240 VAC (with AVR) |

0.7 A or 0.8 A |

|

Single-Phase 100 ~ 120 VAC |

Three-Phase 200 ~ 240 VAC (with AVR) |

1.4 A or 1.5 A |

|

Single-Phase 100 ~ 120 VAC |

Three-Phase 200 ~ 240 VAC (with AVR) |

2.5 A or 3.5 A |

|

Three-Phase 380 ~ 480 VAC |

Three-Phase 390 ~ 480 VAC (with AVR) |

1.5 A or 1.8 A |

|

Single-Phase 100 ~ 120 VAC |

Three-Phase 200 ~ 240 VAC (with AVR) |

4.2 A or 5.5 A |

|

Three-Phase 380 ~ 480 VAC |

Three-Phase 390 ~ 480 VAC (with AVR) |

2.5 A or 3.1 A |

|

Single-Phase 200 ~ 240 VAC |

Three-Phase 200 ~ 240 VAC (with AVR) |

7.0 A or 9.2 A |

|

Three-Phase 380 ~ 480 VAC |

Three-Phase 390 ~ 480 VAC (with AVR) |

3.7 A or 4.36 A |

|

Single-Phase 200 ~ 240 VAC |

Three-Phase 200 ~ 240 VAC (with AVR) |

10 A or 12 A | |

Three-Phase 380 ~ 480 VAC |

Three-Phase 390 ~ 480 VAC (with AVR) |

5.5 A or 6.3 A |

Inverters / VFD for Three-Phase AC Motors

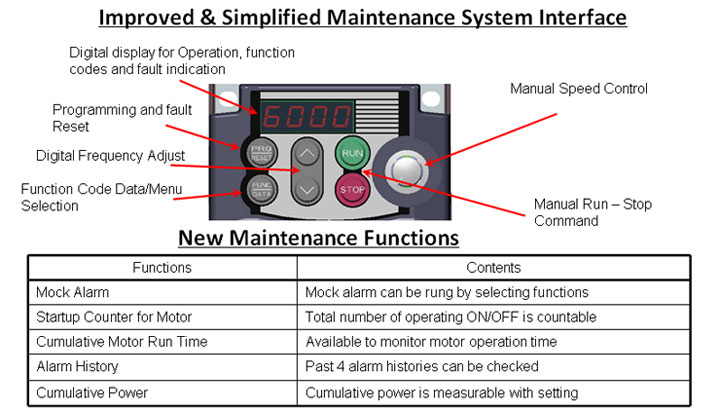

Easy Operation and Maintenance

The FRENIC-Mini (C2) provides simple control and a wide range of functions.

Auto-Tuning

When using the software the inverter automatically detects the motor constants and saves them as parameters in its internal memory. The auto-tuning function enables the dynamic torque vector control, automatic energy saving operation and other advanced motor controls for general purpose motors. Manual input of motor parameters is possible.

Advanced Functions

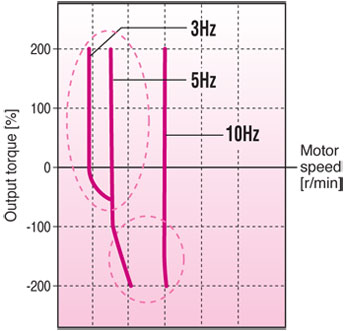

Dynamic Torque Vector Control System

Fuji Electric's original dynamic torque vector control system is known for its top-of-the-line performance, delivering stable torque output even at low speeds. This feature has a wide range of applications; including conveyors and high-inertia loads that demand high starting torque.

Slip Compensation Shortens Setting Time

The slip compensation controller works with voltage tuning for even more accurate speed control at low velocity. This reduces speed control variability and stabilizing creep speed for more accurate stopping in conveyors and similar equipment.

Fastest CPU Processor in its Class

Advanced CPU processes data at twice the speed of previous model. Now 64 MHz.

V/f Control

The FRENIC-Mini series of inverters offer a variety of V/f patterns and torque boosts, which include V/f patterns suitable for variable torque load such as general fans or pumps or for special pump load requiring high starting torque. Under this control the inverter controls a motor with the voltage and frequency according to the V/f pattern specified by function codes. Three point can be set for a non-linear V/f pattern.

Torque Boost

In Auto-Tuning :

This function automatically optimizes the output voltage to fit the motor with its load. Under light load, auto torque boost decreases the output voltage to prevent the motor from over-excitation. Under heavy load, it increases the output voltage to increase the output torque of the motor.

For Greater Control: Manual Mode:

In torque boost constant voltage is added to the basic V/f pattern, regardless of the load, to the given output voltage. To secure a sufficient starting torque manually adjust the output voltage to optimally match the motor and its load by using a function code.

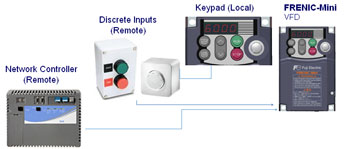

Flexibility of Remote / Local Operation

Switching between Local and Remote operating modes for speed reference and start/stop commands can be chosen using an external digital input or over an RS-485 communication network.

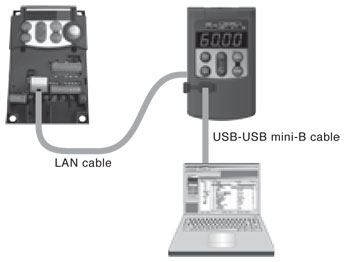

USB Keypad

Optional USB keypad is available along with Enhanced PC Loader Software (FRENIC Loader) connectivity.

Network Capabilities

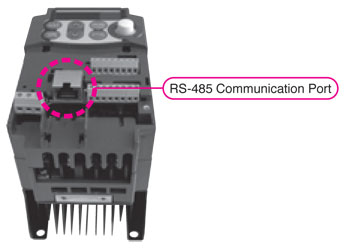

RS-485 Communications Port Standard

Communications can be controlled through the standard RS-485 communications port using Modbus-RTU or Fuji Electric Inverter protocol.

Small & Compact

Side-by-Side Mounting

More than one FRENIC-Mini (C2) inverter can be mounted side-by-side without any gap inside your system control panel, thereby reducing the amount of space required for installation. (Ambient temperature: 40°C (104°F) or lower).

Remote Mount Keypad (TP-E1W)

The keypad permits remote control of FRENIC-Mini, and function setting and display (with copy function).

Remote Operation Cables

This straight cable is used to connect the RS485 Communications card and the remote keypad (TP-E1W).

Item |

Length |

1m |

|

3m |

|

5m |

USB-Equipped Remote Keypad (TP-E1U)

Using the keypad in combination with FRENIC Loader enables a variety of data about the inverter unit to be saved in the keypad memory, allowing you to check the information in any place.

*Additional Accessories are available when selecting Inverter, refer to the product brochure for more information.

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.