Load Elevator

For vertical applications where stopping and holding loads is required Oriental Motor offers a wide range of motors equipped with electromagnetic brake for stopping and holding the load.

Applicable Products

Fixed Speed Systems

For fixed speed or constant speed applications where the load must be held in place or for vertical applications, there are a wide range of AC motors with power-off activated electromagnetic brake.

Type |

Features |

Output Power |

Power Supply |

|

AC Motors with Electromagnetic Brake are suitable for applications where the load must always be held in place. |

6 W (1/125 HP) |

Single-Phase 100-115 VAC Single-Phase 200-230 VAC Three-Phase 200-230 VAC |

|

The brake pack provides instantaneous stop, forward/reverse operation, electromagnetic brake control and open thermal protector detection functions integrated into one unit. These brake packs can sense when the thermal protector is opened, further ensuring the safety of your equipment. The SB50W can be used with induction motors, reversible motors, electromagnetic brake motors and watertight motors with an output range of 1 to 90 W (1/750 to 1/8 HP). |

- | - |

Oriental Motor also offers a range of gear options to reduce the motor speed and generate greater torque as well as a brake pack for use with AC motors to allow for instantaneous stopping.

Parallel Shaft Gearheads |

Right-Angle Gearheads |

Parallel Shaft gearheads reduce the motor speed and generate greater torque. A wide range of gear ratios are available. |

Right-Angle Gearheads are suitable for applications where space saving is required by allowing the motor to be mounted at a right-angle to the conveyor. Solid shaft and hollow shaft models are available. |

Speed Control Systems

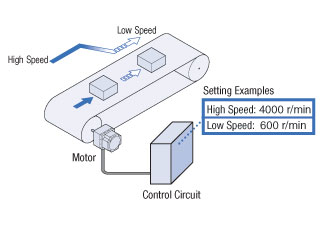

For applications where the speed needs to controlled or vary during operation Oriental Motor offers easy-to-use AC Speed Control Motors as well as Brushless DC Motors & Gear Motors (BLDC Motors) that offer a wide speed control range and constant torque regardless of load.

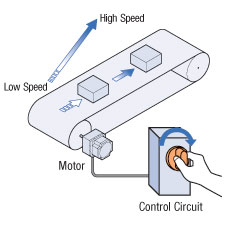

By combining a control circuit with the motor, speed changes can be performed. Speed control motors are optimal for switching between high speed and low speed operation and for arbitrary adjustment of speed.

Setting Multiple Speeds and Switching Speeds |

Arbitrarily Adjusting the Speed |

|

|

Type |

Features |

Output |

Speed Control |

Power |

|

Brushless DC Motors & Gear Motors (BLDC Motors) provide high speed stability, energy saving and space saving. Brushless DC motors also allow for stable speed control even with a fluctuating load and offer constant torque over a wide speed range. |

15 W (1/50 HP) |

80 ~ 4000 r/min |

Single-Phase 100-120 VAC Single-Phase 200-240 VAC Three-Phase 200-240 VAC 24 VDC 48 VDC |

|

AC Speed Control Motors allow for simple settings and basic speed control functions using an AC Motor. Inverters are control circuits that control the power supply frequency and voltage applied to three-phase induction motors in order to control speed. AC speed control motors are motors that include an induction or reversible motor equipped with a tachogenerator (AC generator) for speed detection. By combining these motors with a dedicated control circuit, speed changes can be performed. |

6 W (1/125 HP) |

90 ~ 1600 r/min |

Single-Phase 100-115 VAC Single-Phase 200-230 VAC Three-Phase 200-230 VAC |

Oriental Motor also offers a range of gear options to reduce the motor speed and generate greater torque.

Brushless DC (BLDC) Motor Gear Options

Parallel Shaft Gearheads |

Hollow Shaft Flat Gearheads |

Parallel Shaft gearheads reduce the motor speed and generate greater torque. A wide range of gear ratios are available. |

Direct connection to the drive shaft is possible without using a connecting part which enables equipment space saving. In addition, the hollow shaft flat gearhead enables permissible torque without saturation even at high gear ratios, so the motor torque can be fully utilized. |

AC Motor Gear Options

Parallel Shaft Gearheads |

Right-Angle Gearheads |

Parallel Shaft gearheads reduce the motor speed and generate greater torque. A wide range of gear ratios are available. |

Right-Angle Gearheads are suitable for applications where space saving is required by allowing the motor to be mounted at a right-angle to the conveyor. Solid shaft and hollow shaft models are available |

Position Control Systems

For conveyors that require higher accuracy positioning Oriental Motor offers a wide range of Stepper Motor and Servo Motor solutions. Stepper motors, with their ability to product high torque at a low speed while minimizing vibration, are ideal for applications requiring quick positioning over a short distance. Servo motors are easy to operate and allow for smooth operation with large inertial loads and belt mechanisms. Servo motors are ideal for positioning over long distances using a flat torque characteristic from low to high speeds.

Type |

Features |

|

|

Positioning over short distance |

Stepper Motors are suitable for high accuracy positioning over a short distance and provide high torque even at low speeds. Stepper motors also offer very low vibration and a wide range of features and options such as gearheads, encoders and built-in controllers to meet the specific needs of your application. |

Positioning over long distance |

Servo Motors provide accurate positioning for quick moves or for a long distance moves. All feature a closed loop configuration ideal for variable loads and offer a wide range of gear options and braking or load holding options. The built-in controller (stored data) FLEX also helps for system configuration considerations. |

|

Geared Options

A wide range of gearing options are available to provide higher permissible inertia, higher resolution positioning and higher torque for index table and high inertia applications.

Geared Stepper Motors |

Geared Servo Motors |

Geared stepper motors not only achieve deceleration, high torque and high resolution, but they are capable of driving larger inertial loads compared to a standard motor. A wide range of gearing options are available: |

The servo motor has restrictions on permissible load inertia, but the geared type can be used to greatly increase the load size that can be driven. |

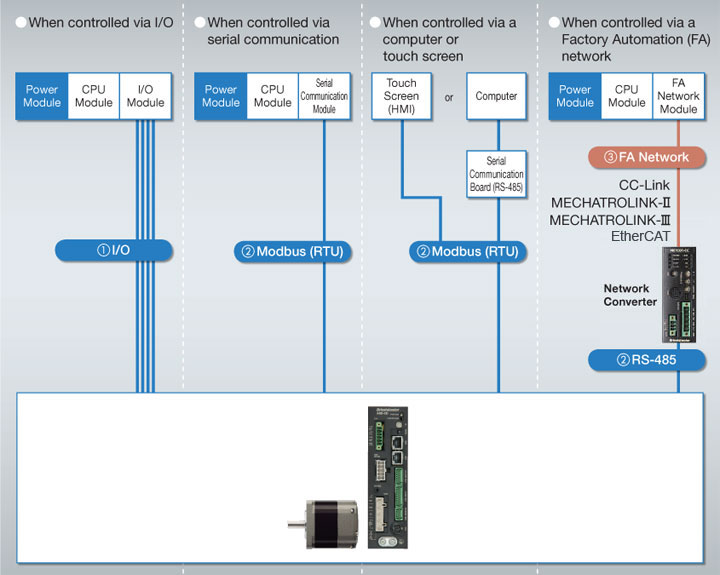

Networked - I/ O, RS-485 / Modbus (RTU) and Factory Automation Applications

Oriental Motor offers Network products under the FLEX concept, meaning each product is equipped with an interface that connects to various master controllers featuring I/O, RS-485 / Modbus (RTU) or Factory Automation. Networked products enable operating data and parameters for each motor to be set at a Master Controller and sent to each driver. In addition, operation commands can be input send set using various communication methods to meet the need of a wide range of available Network Solutions.

Available Network Solutions

1. I/O - Allows the driver to be connected directly to a controller or PLC to configure the operating system with I/O.

2. RS-485 / Modbus (RTU) - Operating data and parameters can be set and operation commands can be input using RS-485 communication. Up to 31 drivers can be connected to each serial communication module. Also there is a function that enables the simultaneous start of multiple axes. The protocol supports Modbus (RTU), enable connection with devices such as a touch screen (HMI) or PCs.

3. Factory Automation Network - Use of a network converter (sold separately) enables support with CC-Link, MECHATROLINK or EtherCAT communication. Operating data and parameters can be set and operation commands can be input using various communication methods.

For Connecting to Factory Automation (FA) Networks

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Connection to FLEX-compatible products is completed with one RS-485 communication cable.

|

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)