BLV Series Brushless DC Motors (DC Input)

BLV Series Brushless DC Motors (BLDC Motors) (DC Input)

The BLV Series is a high power, compact brushless DC motor and driver package with 100W (1/8 HP), 200 W (1/4 HP) and 400 W (1/2 HP) motors. Driver input voltages are 24 VDC and 48 VDC respectfully and is equipped to facilitate battery power input. The driver can be controlled via I/O or RS-485 communications. By adding a parallel gearhead or the hollow shaft flat gearhead, output torques can reach 970 lb-in. An electromagnetic brake is offered for vertical or load holding applications.

Extended functions such as 8 speed ranges, torque limiting and monitoring are available with the MEXE02 software (free download) or through the use of a controller module.

- 24 or 48 VDC

- Network Communications (I/O or RS-485)

- Parallel Shaft, Hollow Shaft Flat Gear or Round Shaft (no Gear)

- Electromagnetic Brake Available

Brushless DC Motor (BLDC Motor) & Gear Motor Lineup

Output Power |

Gear Options |

Available Options |

Power Supply |

Rated Torque |

Speed Range* |

|

Parallel Shaft |

Electromagnetic Brake | 24 VDC |

16 ~ 265 lb-in |

1.8 ~ 30 N·m |

100 ~ 3000 r/min Min: 0.5 (0.4*) [200:1] |

|

Hollow Shaft Flat |

15 ~ 601 lb-in |

1.7 ~ 68 N·m |

||||

Parallel Shaft |

Electromagnetic Brake | 24 VDC |

25 ~ 610 lb-in |

2.9 ~ 70 N·m |

100 ~ 4000 r/min Min: 0.5 (0.4*) [200:1] |

|

Hollow Shaft Flat |

48 ~ 480 lb-in |

5.5 ~ 55.3 N·m |

||||

Round Shaft (no Gear) |

92 oz-in |

0.65 N·m |

||||

Parallel Shaft |

Electromagnetic Brake | 48 VDC |

52 ~ 610 lb-in |

5.9 ~ 70 N·m |

100 ~ 4000 r/min Min: 0.5 (0.4*) [200:1] |

|

Hollow Shaft Flat |

48 ~ 970 lb-in |

5.5 ~ 110 N·m |

||||

Round Shaft (no Gear) |

184 oz-in |

1.3 N·m |

||||

†Cables included

*With OPX-2A Control Module (sold separately).

Brushless DC Motors (BLDC Motors)

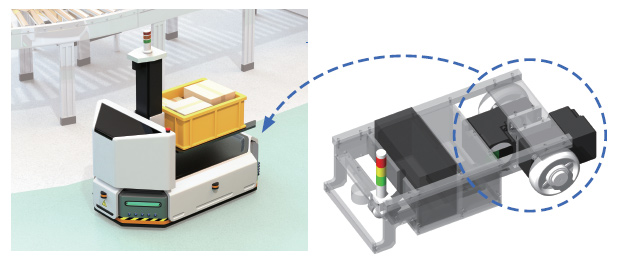

Optimal for Speed Control of Transportation Vehicles, Such as AGVs

- Smooth traveling, non-meandering traveling, wide traveling speed range

- Compact and high-torque drive motor

- Driving continues, even if the battery volrage drops

- Accurate stopping, and load holding when stopped

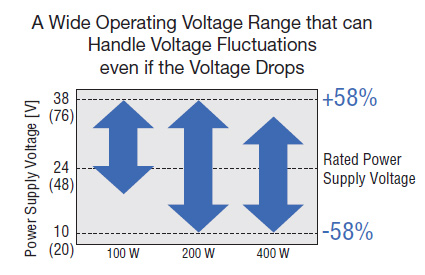

Can be Battery-Operated

A wide operating voltage range that can handle voltage fluctuations even if the voltage drops.

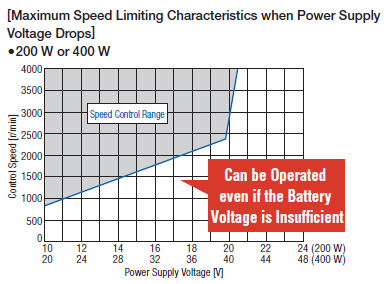

Can be Driven even if the Battery Voltage Drops

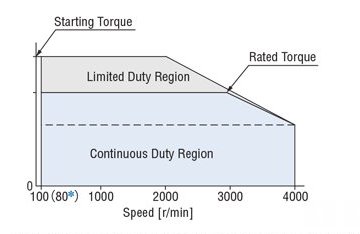

The maximum motor speed of the BLV Series brushless DC motor is 4000 r/min. The speed control range has also expanded to cover velocities from 100 to 4000 r/min (speed ratio of 50:1; measured at the motor shaft), thus allowing you to program operations at various speeds from low to high.

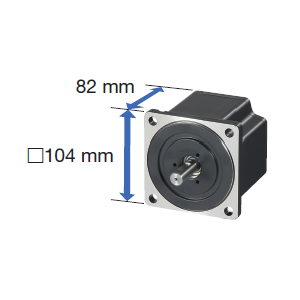

Slim, Yet Powerful Design

A slim body and high output are two key features of a brushless DC motor. The BLV Series does not disappoint users expecting these attributes. From its space-saving compact body in a frame size of 4.09 in. (104 mm), the BLV produces a high output from 1/8 HP (100 W) up to 1/2 HP (400 W).

Wide Speed Control Range and Excellent Speed Stability

Constant rated torque over the entire speed range is possible form low to high. Sufficient torque is acheived without the used torque being limited at low speed, like when a three-phase motor is inverter driven.

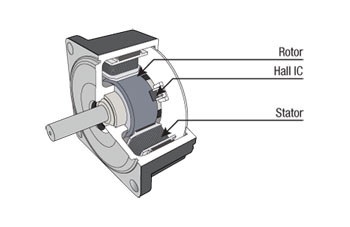

No Brushes = No Maintenance

The Brushless DC Motors (BLDC Motors) do not utilize brushes, which often require replacing and/or maintenance, saving time and cost.

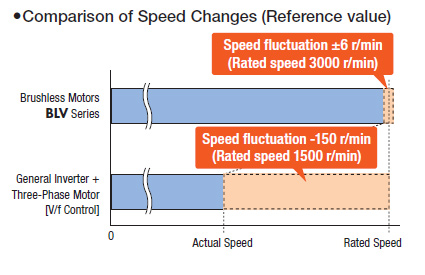

Speed Stability in Feedback Control

The setting speed is compared with the speed feedback signals from the motor at all times to adjust the motor's applied voltage. A stable speed is maintained over the entire speed range from low to high, even when the load fluctuates.

Speed Control Methods

Many Convenient Functions for Speed Control

Besides the basic speed control functions, there are a variety of other functions that suit a wide range of applications.

Acceleration and Deceleration Time |

Acceleration and deceleration times can be set. This allows for smooth starting and stopping with little shock. |

Torque Limiting |

This function limits the output torque of the motor. It outputs a TLC signal when the set limiting value is reached. |

Alarm |

Stops operation and outputs a signal |

Setting |

Outputs a signal at the warning level before an alarm occurs. Motor operation continues. |

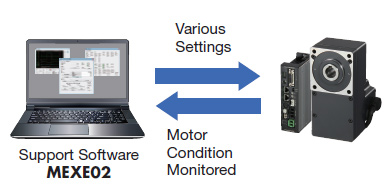

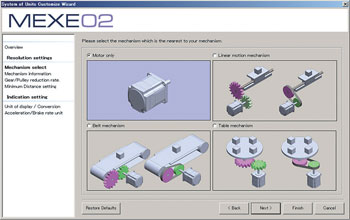

Peace of Mind for Startup and Maintenance with Support Software MEXE02

Control is also Possible via Modbus (RTU) and FA Network

Control Possible from PLC, Touch Screen, etc.

Modbus (RTU) Control

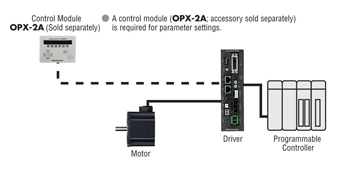

I/O Control System

Operation can be executed easily with I/O control.

I/O Control System

Operating Data & Parameter Settings |

Operation Commands (FWD, REV, etc.) |

||

Operation Data |

Driver potentiometer, control module (OPX-2A) |

I/O |

|

Parameters |

Control Module (OPX-2A) |

||

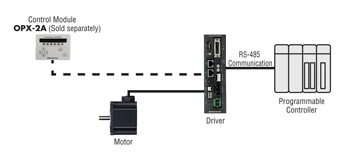

RS-485 Communication System

RS-485 communication lets you set operating data and parameters and enter operation commands. A single programmable controller connects up to 31 drivers and provides multi-axis synchronous starting.

The protocol of the RS-485 communication system supports Modbus RTU, allowing it to easily connect with programmable controllers, touch panels and other devices.

RS-485 Control System

Operation Data & |

Operation Commands |

|

RS-485 communication, control module (OPX-2A) |

RS-485 communication, I/O |

|

- FWD input, REV input and other operation commands can also be controlled from I/O.

- The test operation function is available with the control module (OPX-2A)

- The internal potentiometers for Speed, Acceleration/Deceleration and Torque Limiting are still active even when using either the control module (OPX-2A) or RS-485 communication.

Additional Performance and Functions

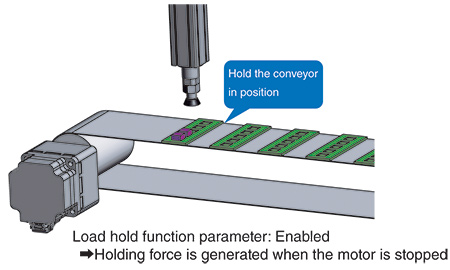

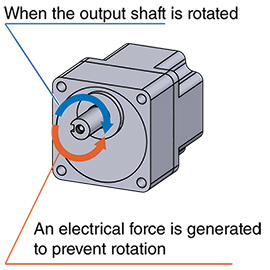

Load Holding Function

The load holding function can be used to electrically hold* the load in place without an electromagnetic brake. For example, work can be performed on the load when it's held in place on a conveyor.

*It can hold a load with a rated torque of up to 50%.

Note: When the power supply to the driver is turned off, the holding torque is lost. It cannot be used to prevent falling when stopped.

No need for a maintenance

It is also suitable for applications where the load needs to be stopped frequently. Since there are no mechanical parts, it contributes to a longer life.

Space saving of equipment

Since no mechanical brake is required, it contributes to space saving and weight reduction in the device.

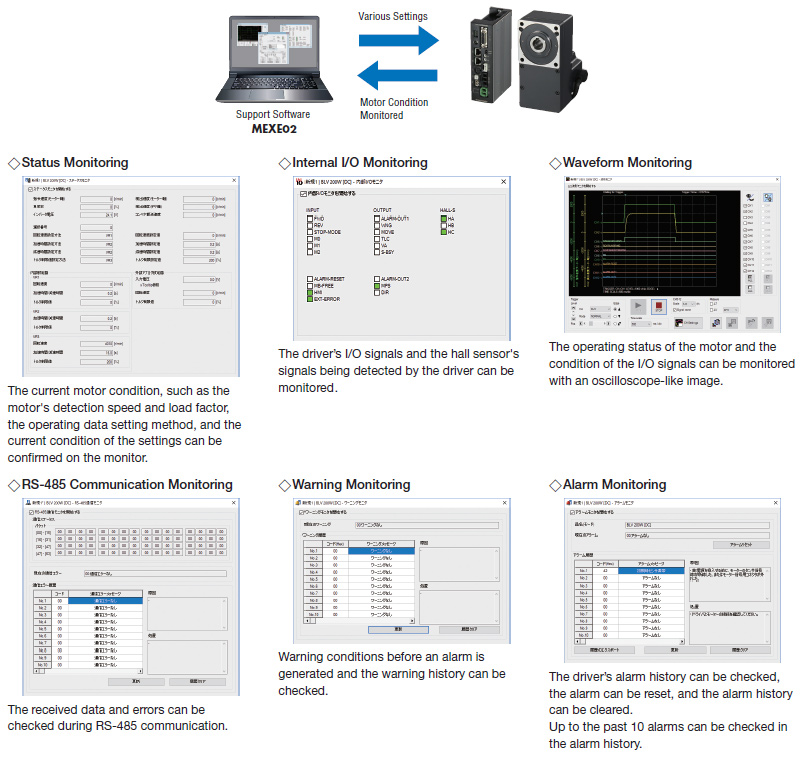

Functionality and performance can be improved by using (available for free download) the MEXE02 Support Software or the optional control module OPX-2A.

Various Settings |

Speed, torque limit, acceleration time, deceleration time, I/O assignment, gear ratio, speed increasing ratio, conveyor gear ratio, conveyor speed increasing ratio, speed attainment range, overload warning level, overload warning function (enable/disable), JOG (test) run speed, JOG (test) run torque, digital/analog input signal selection Up to 16 points of operating data (speed, torque limit, acceleration time, and deceleration time) can be set*1 |

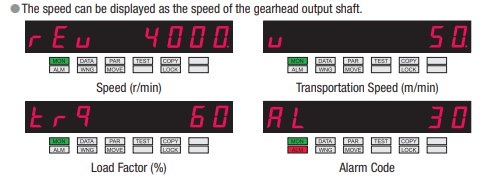

Monitoring Function (OPX-2A) |

Speed, conveyor transportation speed, load factor, operating data No., alarm/ warning (code indication), alarm/warning log (code indication), I/O monitor |

Monitoring Function (MEXE02) |

Status monitor: Speed, gear shaft speed, conveyor speed, load factor, operating selection number, alarm/warning, alarm/warning log I/O monitor: I/O signals, current internal/external potentiometer setting Waveform monitor: Setting speed, detected speed, I/O signals |

Test Function |

I/O test, JOG (test) operation |

Data Copy |

Download, upload, query*2, reset |

*1 Specifications for the RS-485 communication type. Specifications of the standard type are up to 8 points.

*2 This function is only for the control module (OPX-2A).

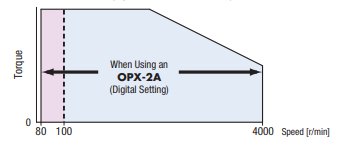

Speed Control Range Expanded to 80 ~ 4000 r/min

The digital speed setting function expands the speed control range to cover 80∼4000 r/min (speed ratio 50:1)

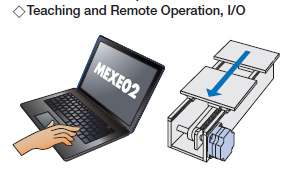

Peace of Mind for Startup and Maintenance with the Support Software MEXE02

By using the support Software MEXE02, data setting, actual operation, and confirmation via each monitor can be performed easily on a computer.

Equipment Startup Status

Operating data can be set on a computer screen. Test operatoins can be performed without connecting o the host system and the operating data is stored as-is.

Operating data can be copied to the driver during use on multiple units and the driver-side data read out. This contributes to reduced system startup time.

Vizualization of Various Infomration Makes "Predicitive Maintenance" Possible

What is "Predictive Maintenance"? The motor's condiition is constantly monitored and protected when signs of changes are observed in order to avoid problems.

Various Digital Indications are Possible (OPX-2A)

Speed, load factor, alarm code, etc. can be displayed digitally.

Long-Life, Parallel Shaft Gearhead

- 100 W (1/8 HP)

- 200 W (1/4 HP)

- 400 W (1/2 HP)

The high-strength gearhead is designed to withstand high-speed revolutions. The rated life of the gearhead is 10000 hours*, which is twice as long as that of our previous gearhead.

Up to 610 lb-in of Torque Possible

[400 W (1/2 HP) Brushless DC Motor with Parallel Shaft Flat Gearhead]

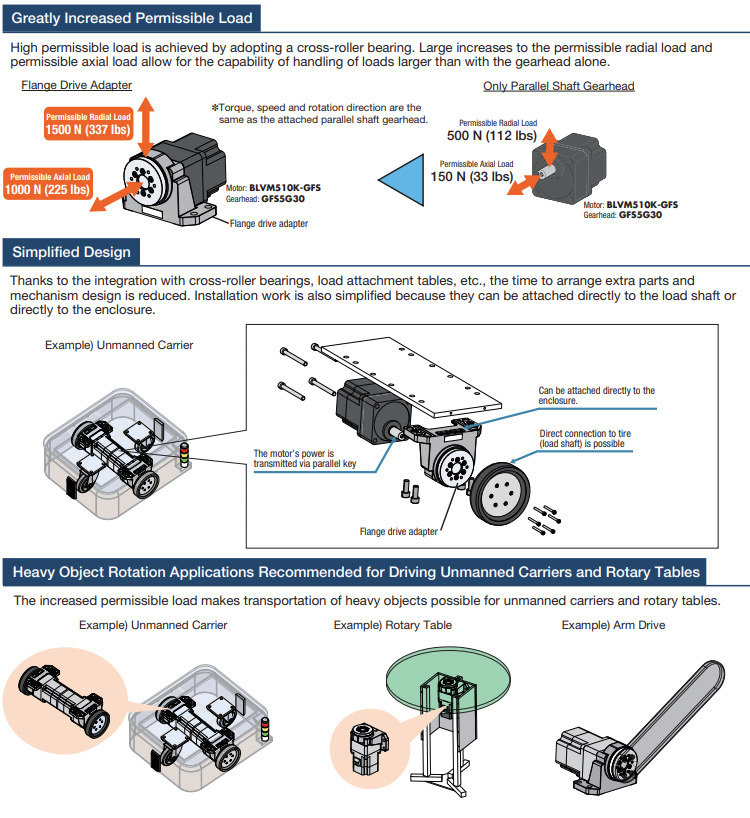

Flange Drive Adapter available for 100 W (1/8 HP) Parallel Shaft Gear Motors

Permissible load has been increased by mounting with a parallel shaft gearhead. Direct mounting of the rotation mechanism to wheels or rotary tables has been simplified, which helps reduce design time.

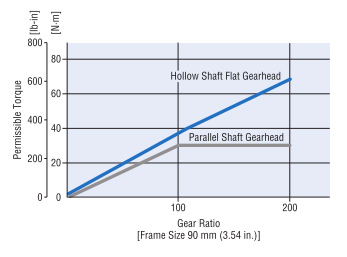

Hollow Shaft Flat Gearhead

- 100 W (1/8 HP)

- 200 W (1/4 HP)

- 400 W (1/2 HP)

Permissible Torque without Saturation

The hollow shaft flat gearhead enables permissible torque without saturation even at high gear ratios. The motor torque can be fully utilized.

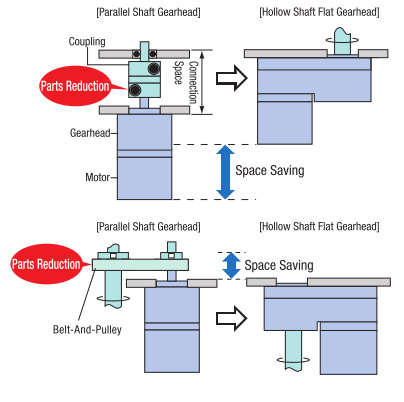

Low Cost

By eliminating parts such as a coupling or belt-and-pulley, the parts cost and labor will also decrease.

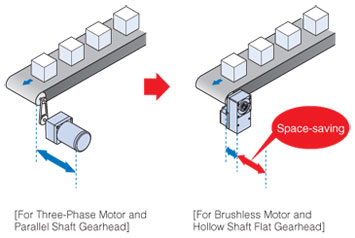

Space Saving is Achieved with a Hollow Shaft Flat Gearhead

The output shaft can be coupled directly to your drive shaft without using a coupling. The flexible installation modes, such as installation on either the front or rear face or by using the center shaft, allows you to reduce the size and installation space of your equipment. Since no shaft-coupling parts are needed, the parts cost and assembly man-hours will also decrease.

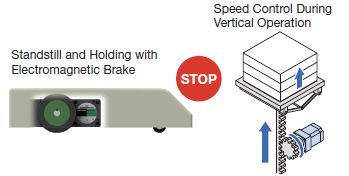

Electromagnetic Brake

- 100 W (1/8 HP)

- 200 W (1/4 HP)

- 400 W (1/2 HP)

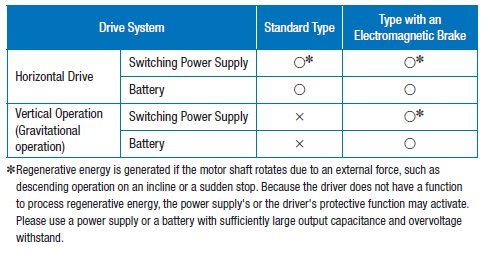

Electromagnetic Brake Models Available for Vertical Drive

The type with an electromagnetic brake is suitable for position holding during standstill and gravitational operation. Note that there are power supply restrictions when using during vertical operation (gravitational operation).

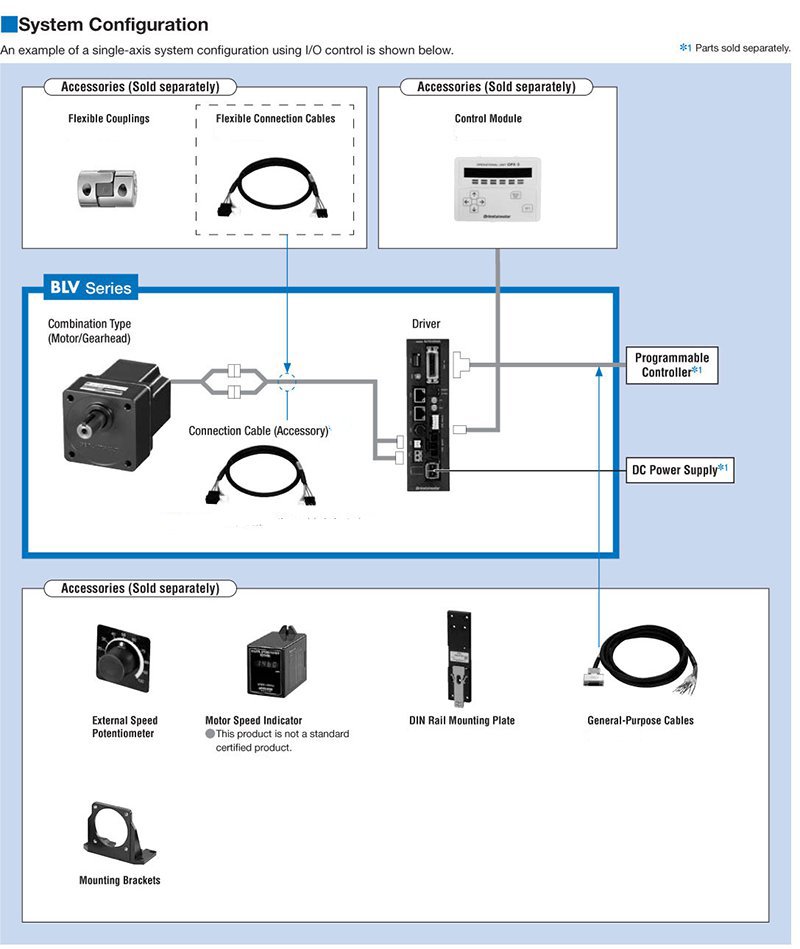

Flexible Connection Cables

Use of flexible connection cables is recommended in applications where the cable will be bent and stretched repeatedly.

*Connection cables required (sold separately)

Control Module

The internal driver parameter settings and data settings can be established and changed. They can also be used for speed and I/O monitoring, teaching, and so on.

Control Options - Data Setting Software

This communication cable is required for connecting to the computer on which the data setting software is installed.

*For use with Stored Data (Network) type

Network Gateways

The communication protocol of the master controller, Factory Automation (FA) network, is converted to Oriental Motor's own RS-485 communication protocol. Connection to Oriental Motor's network compatible products is completed with one RS-485 communication cable.

- Compatible Networks:

CC-Link, MECHATROLINK-II, MECHATROLINK-III, EtherCat

*For use with Stored Data (Network) type

![]()

![]()

![]()

Flexible Couplings

These products are clamp type couplings used to connect a motor or gearhead shaft to the shaft of the equipment.

Mounting Bracket

This is an aluminum die cast mounting bracket for geared motors.

Long, horizontal holes make it easy to make fine adjustments during installation.

RS-485 Communication Cable

RS-485 communication lets you set operating data and parameters and enter operation commands. A single programmable controller connects up to 31 drivers and provides multi-axis synchronous starting.

General Purpose Cables

Dedicated 15-conductor cables for connecting the I/O signal and programmable controller. They are high-quality, noise-blocking, double-shielded cables.

Item |

Length |

| 3.3 ft. (1 m) | |

| 6.6 ft. (2 m) |

DIN Rail Mounting Plate

DIN Rail installation plate for the driver.

Flange Drive Adapter

Permissible load has been increased by mounting with a parallel shaft gearhead. Direct mounting of the rotation mechanism to wheels or rotary tables has been simplified, which helps reduce design time.

*For use with 100W Parallel Shaft Gear Motors

External Speed Potentiometer

Sets and adjusts the motor's speed. Package includes one potentiometer.

(20 kΩ, 1/4 W and with a linear resistance vs. angle curve)

Potentiometer Mounting Plate

DIN rail mounting bracket for the external speed potentiometer.

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.