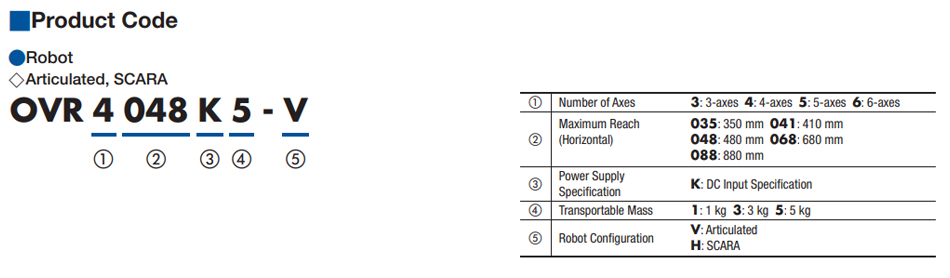

OVR Series Articulated Robots

OVR Series Articulated Robots

The OVR Series Articulated 4-axis, 5-axis, and 6-axis small horizontal transport robots feature a simple mechanism that can be easily controlled and constructed cost-effectively. The OVR Series Articulated 4-axis, 5-axis, and 6-axis small horizontal transport robots. Articulated Robots utilize rotary joints (axis) that allow for more degrees of freedom than other robots types. Articulated Robots structure provide an enhanced range of motion meant to mimic a human arm. This allows a lot of flexibility in the applications they can support in manufacturing and industrial applications. Control with the MRC Series controller and AZ Series motor drivers.

- Parallel link mechanism

- Transportable mass 1 ~ 5 kg

- Compact and lightweight

- Can be combined with an electric linear slide for horizontal travel (5-axis and 6-axis)

Product Lineup

Articulated Robots |

Number of Axes |

Maximum Reach (Horizontal) |

Transportation Mass |

Power Input |

|

480/680/880 mm |

5 kg |

24 VDC |

|

|

350 mm |

1 kg |

24 VDC |

|

|

480 mm |

1 kg |

24 VDC |

Articulated Robots

4-axis |

|

Parallel Link Mechanism |

|---|---|---|

OVR4048K5-V |

|

5-axis |

|

Compact and Lightweight |

|---|---|---|

OVR5035K1-V |

|

6-axis |

|

Approach the Load from Various Angles |

|---|---|---|

OVR6048K1-V |

|

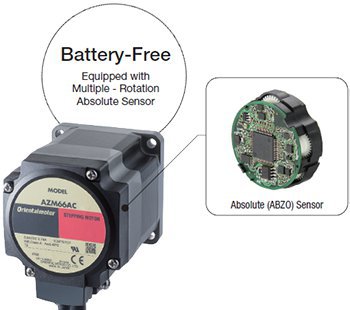

Built-in Battery-Free Absolute Encoder

| The αSTEP AZ Series (DC input) is used for all axes. No external sensors are required, simplifying the wiring. No battery is needed, so maintenance can be reduced. |  |

|---|

Easy Maintenance

Some motors can be replaced by the customer. This cuts down on the burden of maintenance (both cost and time) after deployment.

*Oriental Motor also replaces motors during maintenance. Please contact your nearest Oriental Motor sales office.

Customizable

The arm length of a 4-axis articulated robot can be customized according to the customer's application.

(Variable reach length: 580 mm, 780mm)

Simple Control with a Robot Controller

Knowledge of "Networks", "Ladder Programs", and "Kinematics operations" is needed to run robots.

OVR utilizes a robot controller, making it easy to start up and control the robot, even without robot control experience.

Product Line

Programming Software MRC Studio

|

MRC Reality (AR App for Mobile)

We have an iPhone/iPad app that allows a robot to be seen in real space to simulate its operation. This simulator allows you to make the small robot OVR appear in the actual space and check its size and range of motion. Please use it to check the size and mechanism movement that are difficult to grasp from catalog information alone. Please contact our technical support for the details.

Use your smartphone or tablet

Download here for free

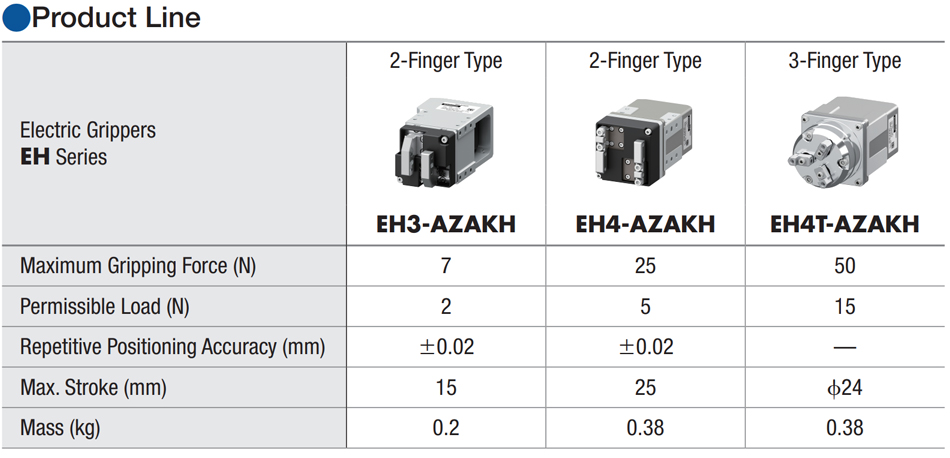

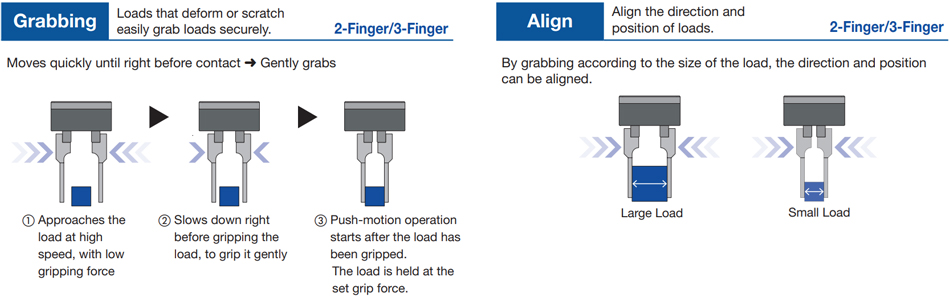

End Effector

The EH Series of electric grippers equipped with the αSTEP AZ Series can be controlled as an end effector by the robot controller.

Applications

The EH Series of electric grippers equipped with the αSTEP AZ Series can be controlled as an end effector by the robot controller.

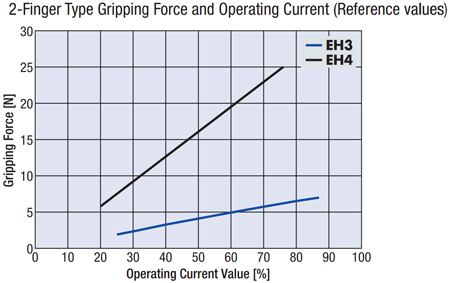

Fine Gripping Force Control

Fine current control allows the gripping force to be finely changed and adjusted.

Grips everything from delicate parts to slippery loads appropriately, gently or firmly as needed.

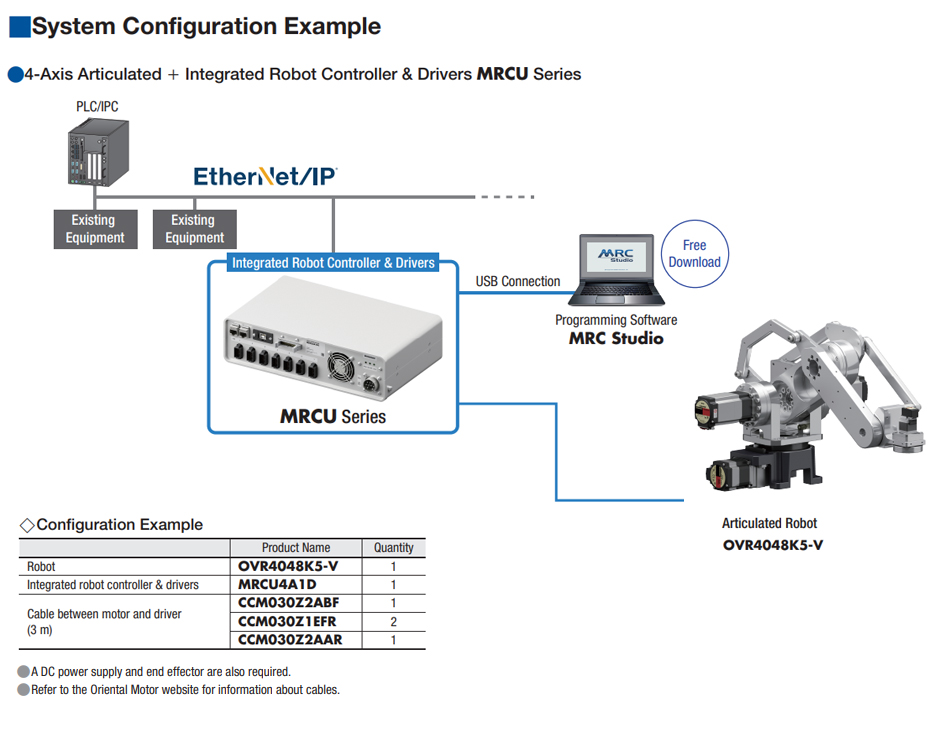

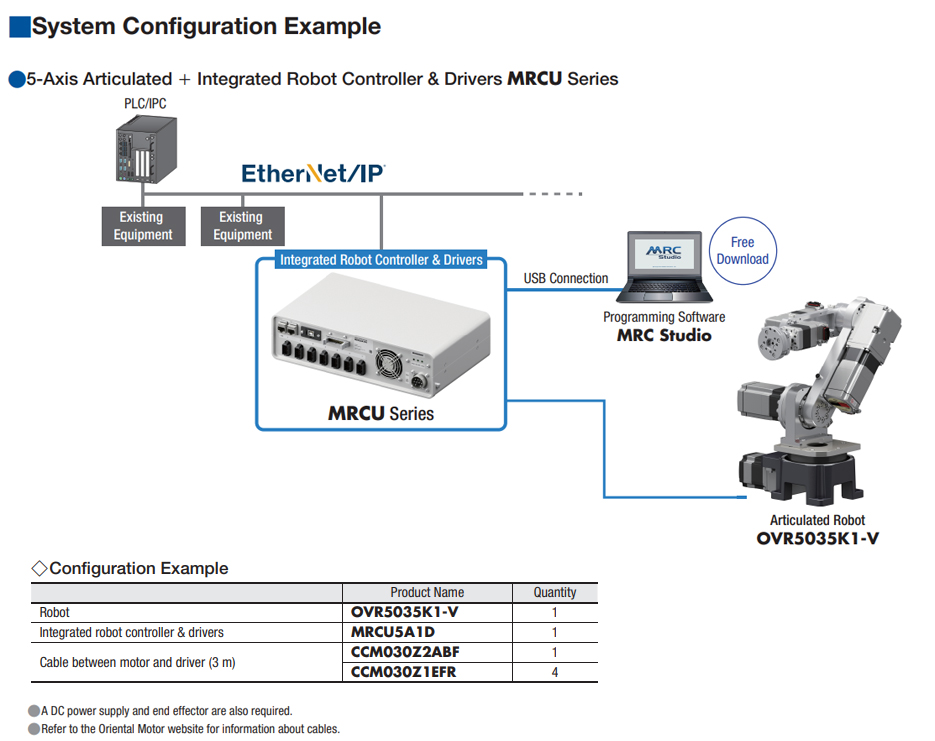

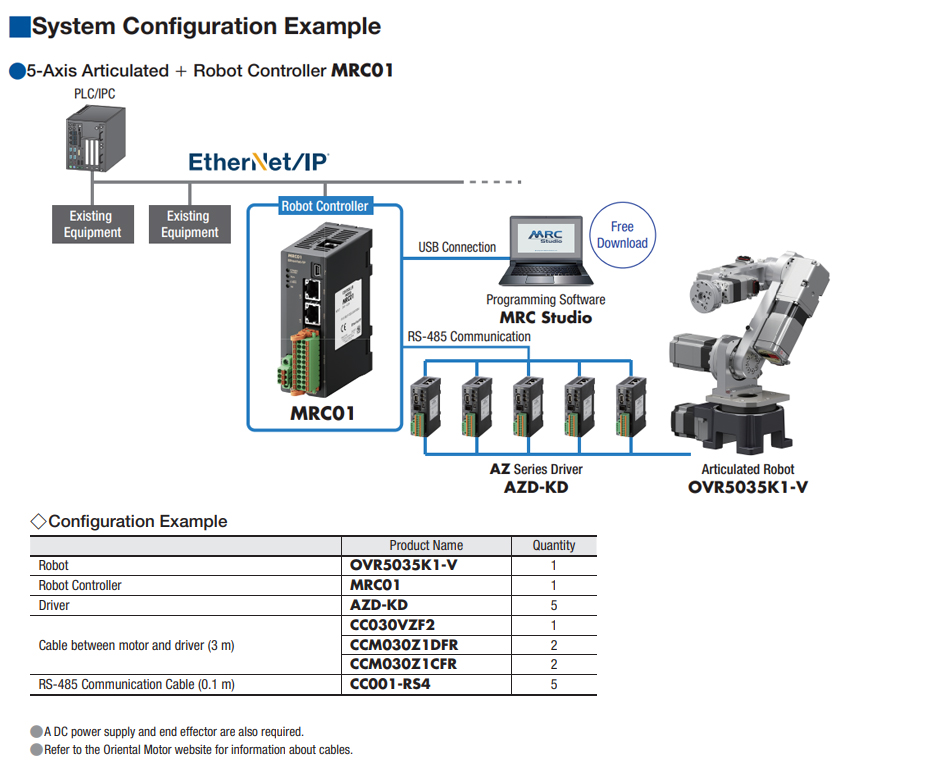

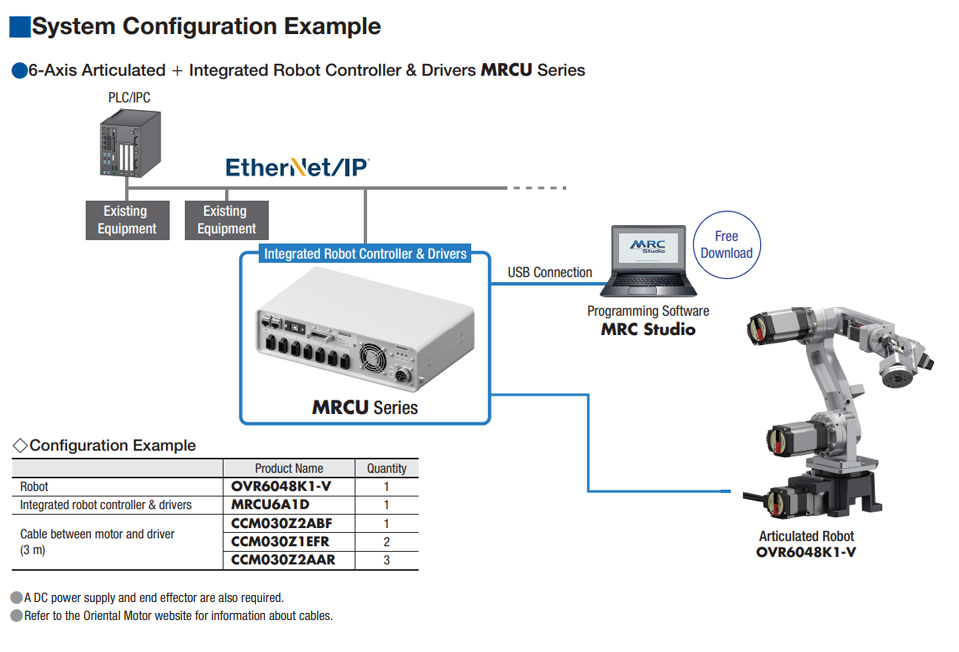

System