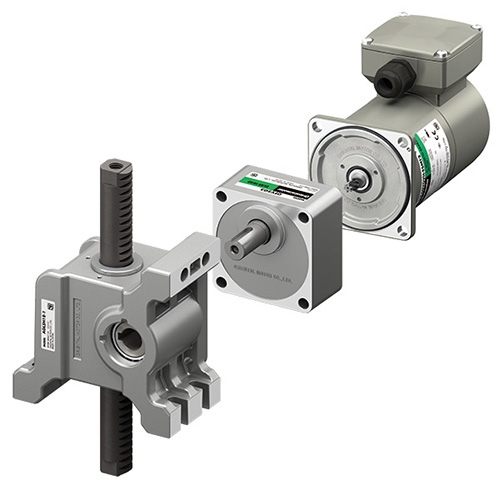

Rack and Pinion System L Series - AZ Series Equipped

Linear Head Rack and Pinion System LJ Series - KIIS Series Compatible

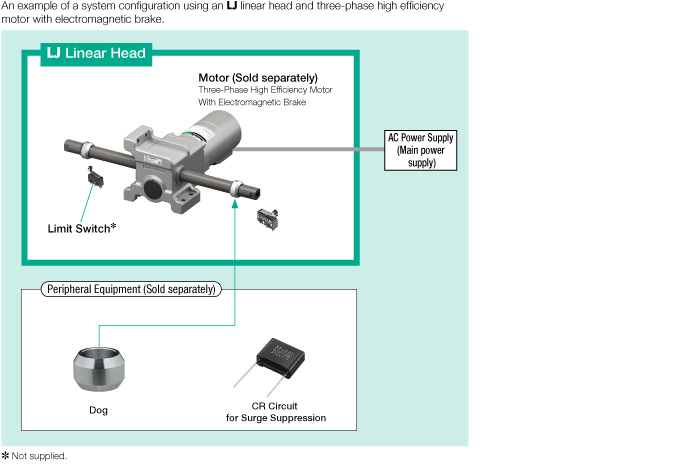

When the LJ linear head with rack and pinion mechanism is attached to a parallel shaft gearhead and motor, linear motion such as pushing, pulling, raising and lowering is possible. Perfect for high load or long stroke applications. Use with Three-Phase AC Induction Motors KIIS Electromagnetic Brake type.

- Horizontal or Vertical movement

- 200 kg Maximum Transportable Mass

Product Lineup

Driver Power Input |

Actuator |

Options |

Max. Trans. Mass |

Max. Speed |

Stroke |

AC Input |

Electromagnetic Brake |

200* |

500 |

100 ~ 700 |

*Max. Vertical Transportable Mass varies by Rack Length.

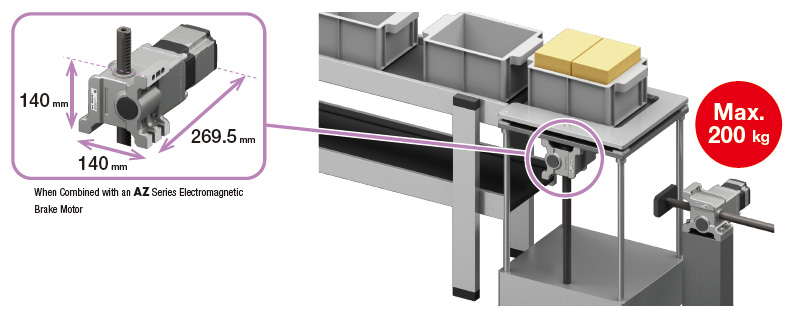

A Maximum Transportable Mass of 200 kg in a Compact Size

200 kg Maximum Transportable Mass*

Large-diameter pinions and stronger gears enable a maximum transportable mass of 200 kg*

*The maximum transportable mass depends on the gearhead's gear ratio and combined motor.

700 mm Maximum Stroke Length

Product line with strokes from 100 to 700 mm

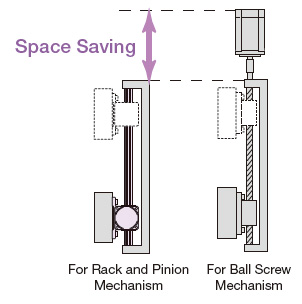

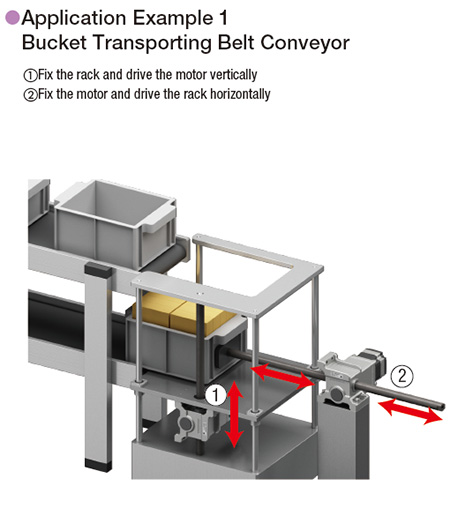

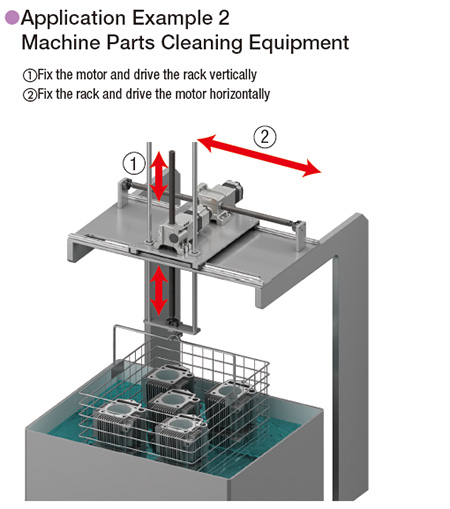

Fix the Rack for Effective Use of Space

The motor itself can run on its own by fixing both ends of the rack. It is effective for equipment where motor space is difficult to secure.

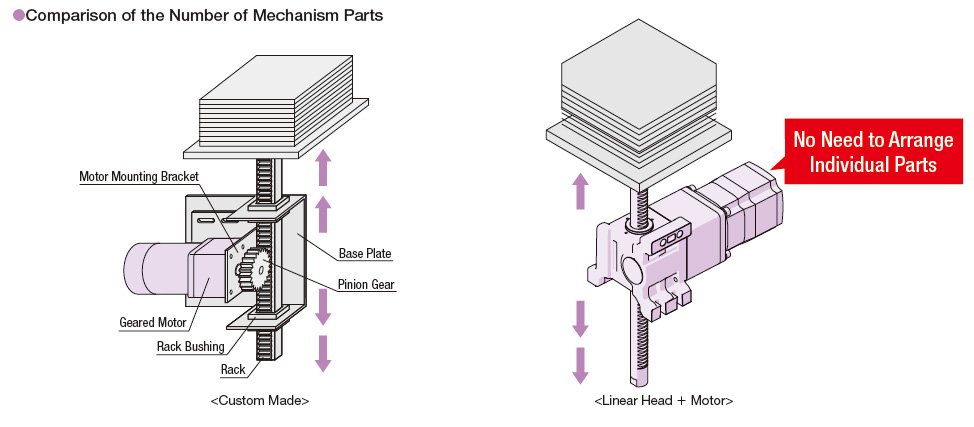

Contributes to Improved Design Efficiency

Reduces Time from Design to Startup

Compared to a self-built rack and pinion mechanism, the number of parts is reduced, the amount of labor for design and assembly can be reduced.

Easy Assembly with a Parallel Shaft Gearhead

The stucture is simple. Just insert a parallel shaft gearhead into the linear head and fix it with screws. This makes both installing to the equipment and performing motor maintenance easy.

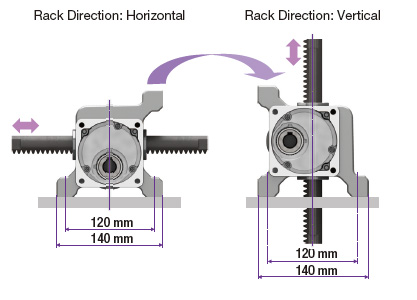

Rack Can be Installed in Horizontal or Vertical Orientations

The structure allows for mounting in both horizontal and vertical directions. The ability to freely select mounting direction contributes to improved ease of design and cost reductions through the sharing of parts.

Applications

The rack and pinion mechanism, which can be used in a variety of applications, is a product that can be selected just like a component, and is easy to use.

High Performance AC Gear Motors

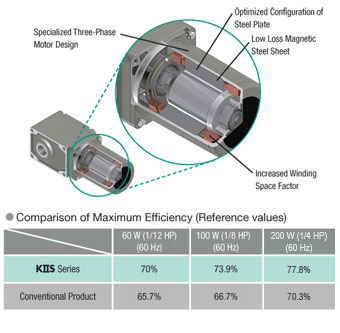

High Efficiency at a Maximum of 77.8%*

Specialized components and optimal magnetic design are used to make high efficiency three-phase motors with a maximum efficiency of 77.8%*. Motors are fanless, with increased motor output and significant loss reduction.

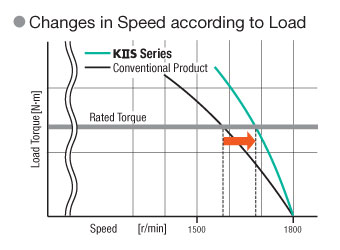

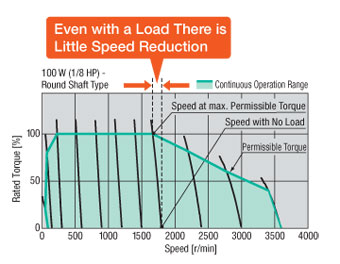

High Performance

Characteristics have been improved through pursuit of the specifications required for the three-phase motor and a review of the design to create a high-performance motor with little speed reduction even with a large load.

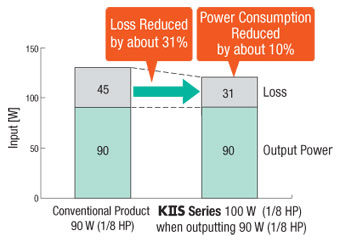

Power Consumption Reduced by up to 10%

Compared to a conventional 90W product under the same conditions, power consumption is reduced by a maximum of about 10%, contributing to the the equipment's energy savings.

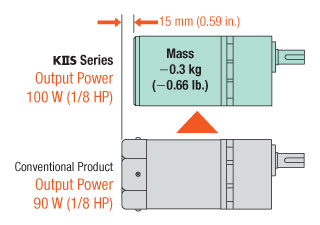

Increased Motor Output

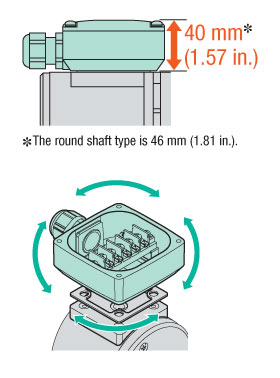

Output power of 100 W (1/8 HP) in a 90 mm (3.54 in.) frame size is achieved through increased efficiency. An overall length 15mm (0.59 in.) shorter than the conventional product contributes to equipment downsizing.

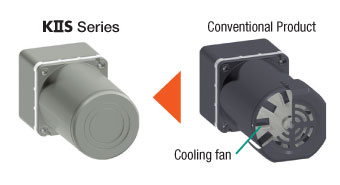

Fanless

With reduced loss, there is less heat generation in the motor, so the cooling fan is no longer needed. With no cooling fan, dust is not blown around.

Equipped with an Easy-to-Wire, Slim Body Terminal Box

This new shape of terminal box is designed to make wiring the terminal block easier. It has a slim body, with a cable outlet that can be rotated in 90° increments for 4 possible directions.

Best Characteristics Achieved when Combined with Inverter

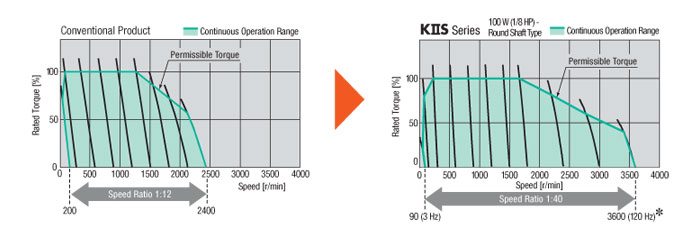

Wide Range of Speeds

Speed can be controlled over a wide range using an inverter, from 3~120 Hz*. Also, with improved characteristics, high torque can be exerted even at low speeds.

Improved Speed Stability

Because it is a high-performance motor with little speed reduction even with a large load, stabilized speed control is possible.

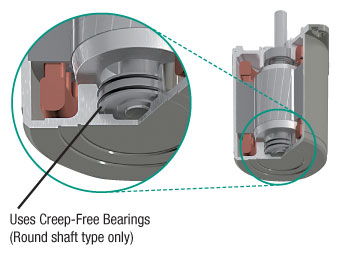

Handles High-Speed Rotation (Round shaft type)

Creep-free bearings, etc. are used in the round shaft type and components capable of handling high-speed rotation have been selected and designed for inverter control.

Electromagnetic Brake

These products have built-in power-off activated electromagnetic brakes. When power is accidentally cut off due to a blackout or other unexpected events, the electromagnetic brake holds the load in position to prevent it from dropping or moving. Also, when the motor is at standstill, it can be held by the electromagnetic brake. It is possible to suppress the heat generated from the motor by turning off the motor current.

Inverter / VFD

With its high functionality, compact design, simple operation, built-in network capabilities and global compatibility, the new FRENIC-Mini (C2) elevates the performance of a wide range of devices and equipment--including conveyors, fans, pumps, centrifugal separators, and food processing machines--to give you the system integration, energy efficiency, reduced labor, and lower overall costs you're looking for.

- Single-Phase 115 VAC or 230 VAC input, Three-Phase 230 VAC or Three-Phase 460 VAC input.

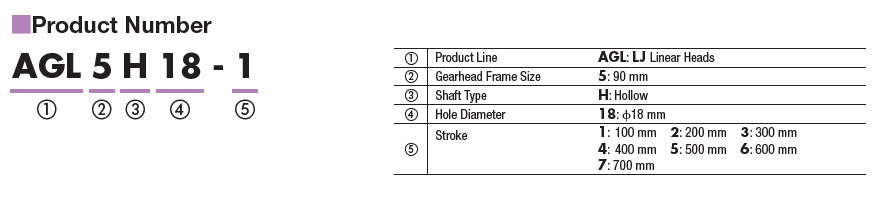

Product Number Code

System Configuration

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.