Modbus (TCP, UDP) Network Products

Modbus TCP and Modbus UDP are variants of the Modbus protocol that use different communication protocols to transmit Modbus messages. The message format is the same as Modbus (RTU).

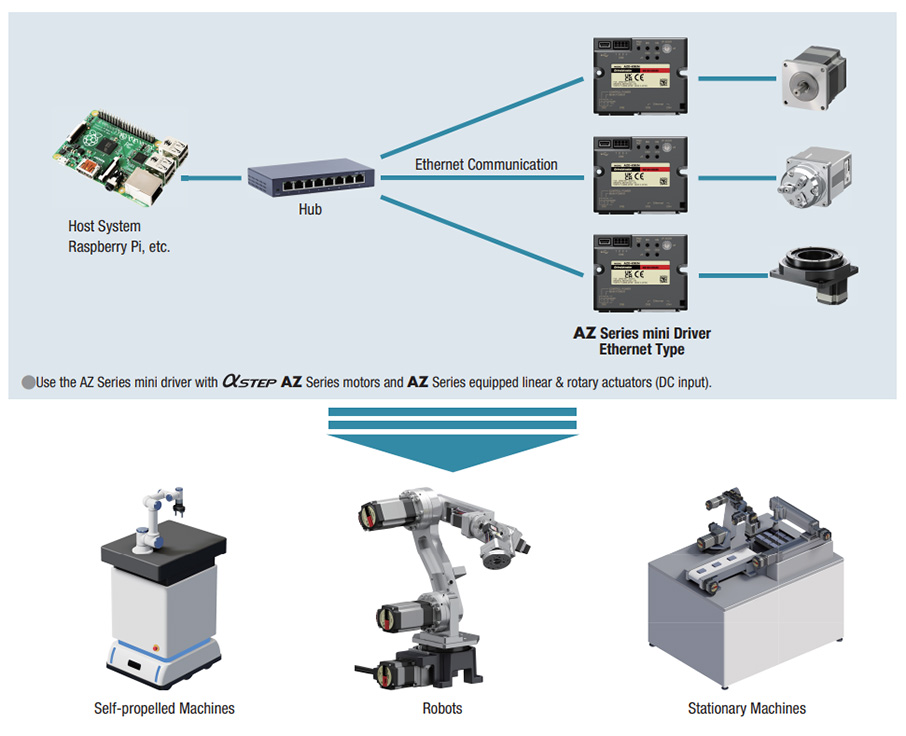

- Direct connection to a single-board computer

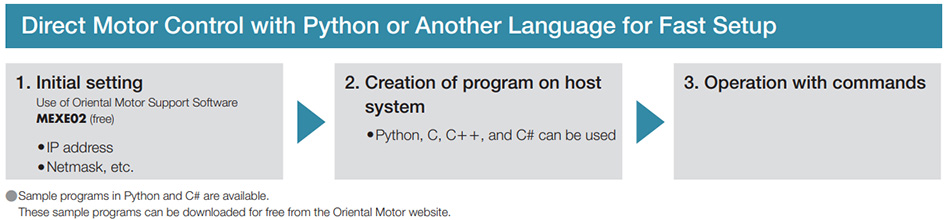

- Use Python or other languages on host system for quick startup

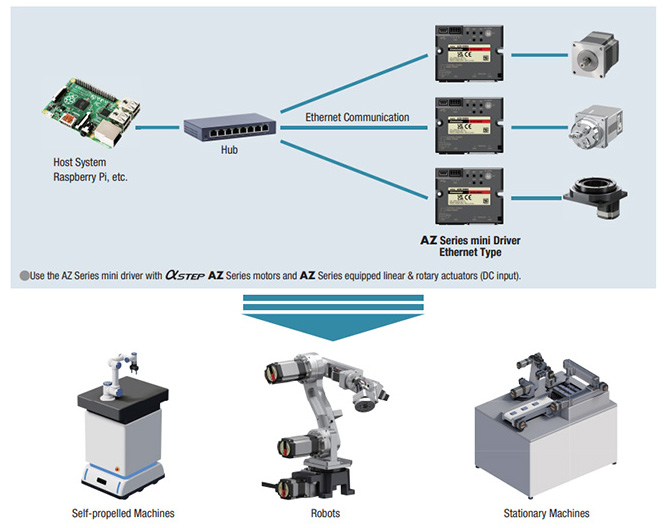

- Support wireless systems over Ethernet

Network control via Modbus (TCP, UDP) can simplify wiring, reduce man-hours, and improve maintenance and performance. This results in a shorter development time and increased reliability and service life of the equipment.

Modbus is a registered trademark of Schneider Automation Inc.

Can be Directly Connected to a Single-board Computer or PC without the Use of a PLC

Direct Motor Control with Python or Another Language for Fast Setup

Build a Wireless System over Ethernet

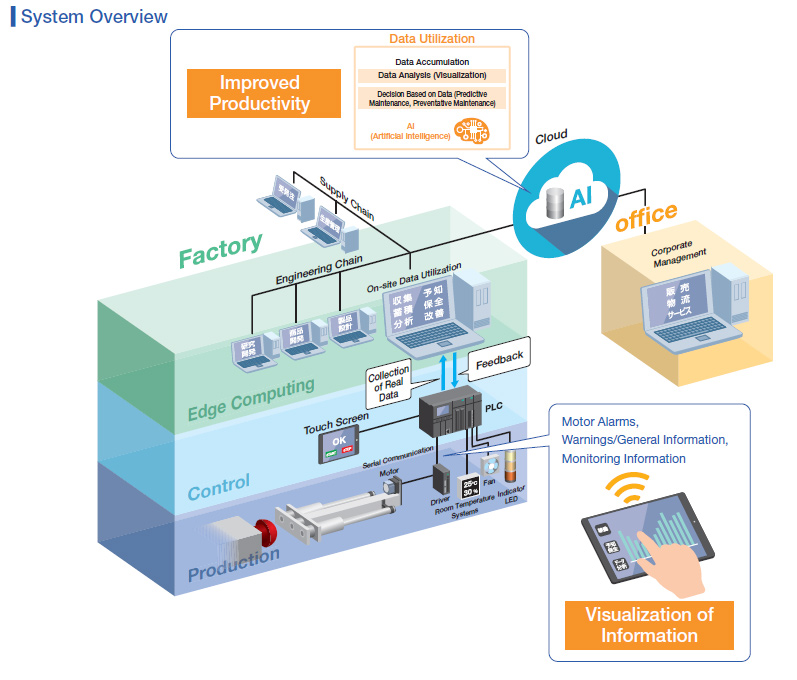

Contributes to Analysis of Conditions

Increased productivity is sought in manufacturing plants. At the same time, it is imperative to continue utilizing the knowledge of human experience through the use of Artifi cial Intelligence (AI). In order to use AI, it is important to collect, digitize and analyze the day to day “changes in conditions". Oriental Motor has created a wide lineup of products capable of outputting the various changes in conditions of motors.

Predictive Maintenance Using IoT (Internet of Things)

In order to detect early signs of failure, it is important to monitor changes in operating conditions daily. One way to do this is to visualize position displacement due to fluctuation in temperature and operation time. This video demonstrates how the AZ Series works with an IoT setup to continuously monitor feedback information. Using this information, overall health of components can determined and manufacturing and productivity can be improved.

Industrial Network Communication for Automation and Motion Control

Oriental Motor offers industrial network communication products under the FLEX concept, meaning each product is equipped with an interface that connects to various industrial networks and master controllers featuring I/O; such as PLC, HMI or serial communication such as RS-485 / Modbus (RTU).

FLEX is the generic name for products that are used for Factory Automation (FA) network control via I/O control, Modbus (RTU) control, or a network converter. FLEX products enable easy connection, easy control, and reduce the complexity of system configuration.

The Advantages of FLEX Industrial Network Communication Products

- Simple Wiring

- Energy Saving

- Time Saving

- Low Cost

Modbus (TCP, UDP) Compatible Products

Products that can be connected via network communication*.

*Network compatible drivers required for network communication.

NOTE: Modbus (TCP, UDP) only available for DC Input Drivers.

αSTEP AZ Series Stepper Motors with Mechanical Absolute Encoder

The αSTEP AZ Series stepper motors offer high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires αSTEP AZ Series Driver.

- Battery-Free, Mechanical Absolute Encoder Stepper Motors

- Closed Loop Performance, No Hunting or Gain Tuning

- DC Input

- Parallel Shaft and Right Angle Geared Types for Higher Torque, Space Savings

- Electromagnetic Brake Type Available

- αSTEP AZ Series Stepper Motor Driver Required*

αSTEP AZ Series Linear Actuators

Motors offer excellent controllability and are therefore used as the drive sources of various automated equipment. In many cases a motor is combines with various mechanical components such as a ball screw, belt and pulley, and rack and pinion to convert the motor rotation to a different type of motion needed to drive the equipment. Oriental Motor has various linear actuators consisting of a motor assembled with the necessary mechanical components to meet the various needs of automated equipment.

- Electric Slides, Electric Cylinders, Compact Linear Actuators, Electric Grippers and Rack-and-Pinion Systems

- Battery-Free, Mechanical Absolute Encoder Stepper Motors

- DC Input

- Electromagnetic Brake Type Available

- αSTEP AZ Series Stepper Motor Driver Required*

αSTEP Closed Loop AZ Series Absolute Encoder Hollow Rotary Actuators

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an αSTEP absolute encoder AZ series closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

- Integrated actuator and stepper motor makes design easier

- Vertical or Horizontal Mount Motor Types

- Easy Home Setting and Return-to-Home without need for sensors

- Large-diameter hollow output table

- DC Input

- αSTEP AZ Series Stepper Motor Driver Required*

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)