AC Motors & Gear Motors > Constant Speed AC Motors > Clutch & Brake Motors

Clutch & Brake Motors

Clutch & Brake Motors

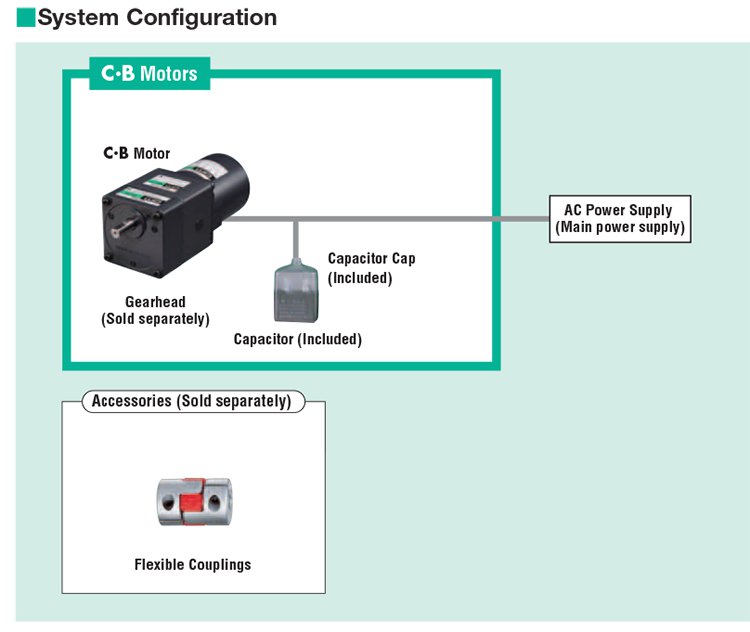

This compact, precision AC motor is equipped with an internal clutch and brake mechanism for use with a gearhead. This combination makes it the ideal motor for applications involving frequent START/STOP operation, positioning, indexing, jogging and incremental feeding. CB motors have a 3.54 in. (90 mm) frame size and come in output powers of 40, 60, 90 W (1/19, 1/12 and 1/8 HP).

- Parallel Shaft Gear

- Single-Phase 110/115 VAC

Questions? We're Here to Help

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)