αSTEP Hybrid Servo Motor / Stepper Motor Drivers

AZ Series Closed Loop Absolute Hybrid Servo Motor / Stepper Motor Drivers

The αSTEP AZD Stepper Motor Drivers offers superior high speed performance, high functionality and closed loop control. There are no external sensors to buy as the motor and driver complete the system. Advanced operation and function control is included through our MEXE02 software (free download). The αSTEP AZD Stepper Motor Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input, Pulse Input with RS-485 Communications or Built-in Controller (Network), EtherNet/IP™, EtherCAT, PROFINET Compatible Types

- For use with AC Input αSTEP AZ Series Stepper Motors

![]()

AR Series Hybrid Servo Motor / Stepper Motor Drivers

The αSTEP ARD Drivers offers superior high speed performance, low vibration and closed loop control. Available in a stored data (network) driver or pulse input driver. Advanced operation and function control is included through our MEXE02 software (free download). The αSTEP ARD Drivers can perform quick positioning operations over a short distance without the need for tuning, while providing smooth performance.

- Built-in Protective Functions

- Pulse Input or Built-in Controller (Network) Types

- For use with αSTEP AR Series Motors

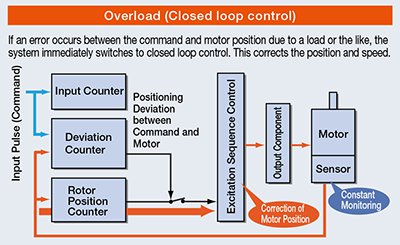

Closed Loop Performance

These stepper motors use our αSTEP closed loop technology to maintain positioning operation even during abrupt load fluctuations and accelerations without hunting or gain tuning. The rotor position detection sensor monitors the rotation speed and amount. When an overload condition is detected, it will instantaneously regain control using the closed loop mode. When an overload condition continues it will output an alarm signal, thereby providing reliability.

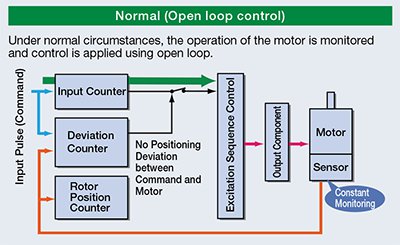

Normally Operates in Open Loop Control for the Same Ease of Use as a Stepper Motor

High Response

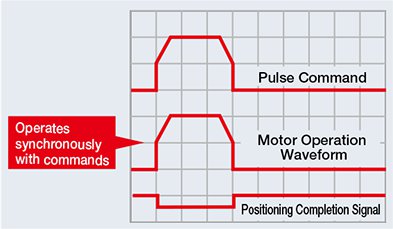

By utilizing the high responsiveness of the stepper motor, moving a short distance for a short time is possible. The motors can execute commands without lag.

Holding the Stop Position without Hunting

During positioning, the motor stops with its own holding force without hunting. Because of this, it is ideal for applications where the low rigidity of the mechanism requires absence of vibration upon stopping.

Tuning-Free

Because it is normally operated with open loop control, positioning is still possible without gain adjustment even when the load fluctuates due to the use of a belt mechanism, cam or chain drive, etc.

Switches to Closed Loop Control during Overload for More Reliable Operation like a Servo Motor

Continues Operation Even with Sudden Load Fluctuation and Sudden Acceleration

It operates synchronously with commands using open loop control during normal conditions. In an overload condition, it switches immediately to closed loop control to correct the position.

Alarm Signal Output in Case of Abnormality

If an overload is applied continuously, an alarm signal is output. When the positioning is complete, and END signal is output. This ensures the same level of reliability as a servo motor.

No Gain Tuning

Gain tuning for servo motors is critical, troublesome and time-consuming. Since these are stepper motors, there are no gain tuning requirements. Low rigidity applications, such as a belt and pulley system, are ideal for closed loop stepper motors.

Types of Servo Motor Drivers

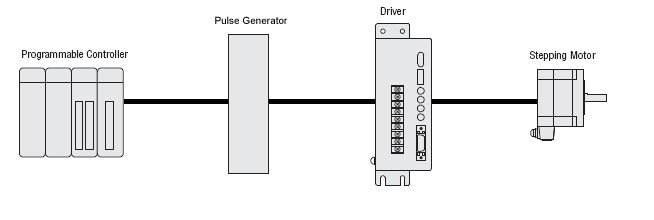

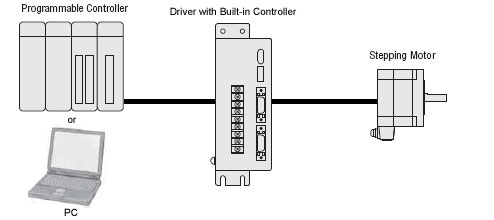

Drivers that operate in the pulse input mode and built-in controller mode are available. You can select a desired combination according to the required operation system.

Pulse Input Drivers

The motor can be controlled using a pulse generator provided by the user. Operation data is input to the pulse generator beforehand. The user then selects the operation data on the host programmable controller, then inputs the operation command.

Built-in Controller (Stored Data or Stored Program) Type Drivers

The built-in pulse generation function allows the motor to be driven via a directly connected personal computer or programmable controller. Since no separate pulse generator is required, drivers of this type save space and simplify wiring.

Hybrid Servo Motor / Stepper Motor Product Comparison

Product Series |

||

|

|

|

|

Features |

Closed Loop, |

Closed Loop, |

Basic Step Angle |

0.36° |

0.36° |

Driver Power Input |

AC |

AC |

Frame Sizes |

1.65 in. (42 mm) |

1.65 in. (42 mm) |

Available Options |

Geared Type |

Geared Type |

Max. Holding Torque |

42 oz-in up to 752 lb-in |

42 oz-in up to 320 lb-in |

0.3 N·m up to 85 N·m |

0.3 N·m up to 37 N·m |

|

Learn More |