Features of the CVK Series Stepper Motor and Driver Package

Stepper motors are used in a wide variety of applications because of their ease of use and accurate positioning. In recent years, though, most users demand high torque, low vibration, and higher accuracy.

The CVK Series is a stepper motor and DC input driver package with higher torque, lower vibration, and higher accuracy than conventional stepper products. We have developed a 1.8° product with an emphasis on torque, and a 0.72°/0.36° product that stresses low vibration and high accuracy. The CVK Series is also highly compatible between the versions, allowing for easy standardization.

The characteristics and features of the CVK Series are introduced here:

1. Introduction

Stepper motors are used in a wide variety of applications due to their ease of use and highly accurate positioning features. In recent years, the demands for high torque, low vibration and high accuracy are constantly being required.

The CVK Series is a DC input stepper motor and driver package with higher torque, lower vibration and higher accuracy than conventional stepper products. The 1.8° stepper motor and driver package ("1.8° package") focuses on torque and the 0.72°/0.36° stepper motor and driver package ("0.72°/0.36° package") provides low vibration and high accuracy. The drivers for the 1.8° and 0.72°/0.36° packages are highly compatible. Therefore, it is possible to select a motor based on certain characteristics as the two packages' mounting characteristics are similar, allowing for easy standardization. Replacing the motor can also be done easily.

Drivers for stepper motors are available in either AC or DC power-supply voltage. The DC type driver is usually less expensive, more compact and can be easily mounted in equipment. The CVK Series is developed for the DC power-supply voltage and is suitable for applications that require the driver to be mounted in the equipment (refer to Figure 1).

2. Product Line of the CVK Series

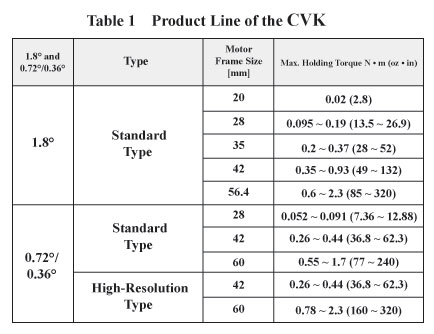

The CVK Series offers a wide range of packages, both with the 1.8° and 0.72°/0.36° stepper motors. The high-resolution type with the lowest vibration and highest accuracy offers exceptional performance (refer to Table 1).

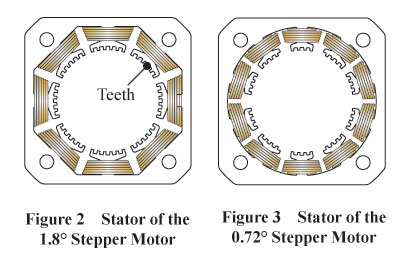

The difference between the 1.8° and 0.72°/0.36° stepper motors is in their structure. Figure 2 shows the stator of the 1.8° stepper motor and Figure 3 shows the stator of the 0.72°/0.36° (specifically 0.72°) stepper motor.

Compared to the 0.72° stepper motor, the 1.8° stepper motor has a lower number of windings (number of phases) and thus the number of turns in a coil is higher as well as the number of teeth on the stator, resulting in higher torque.

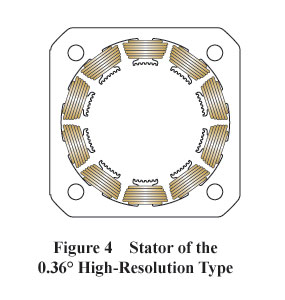

The difference of vibration between the 1.8° and 0.72°/0.36° stepper motors is due to the different number of phases. The 1.8° and 0.72°/0.36° stepper motors' motor vibration should be the same, as long as the step angle is the same, in principle. However, in reality torque generated by each phase has small variance, causing the motor to vibrate. Because the 0.72°/0.36° stepper motor has a higher number of phases, the variance of generated torque is dispersed, resulting in lower vibration than the 1.8° stepper motor. For the same reason, it is highly accurate at positioning. Figure 4 shows the stator of the 0.36° high-resolution type stepper motor.

The high-resolution type has finer and smaller teeth than the standard type (0.72°). Because of these features, the variance of generated torque is dispersed, enabling it to perform not only with lower vibration but also higher positioning accuracy.

3. Features of the CVK Series

The CVK Series has the following features:

- Higher torque compared to conventional stepper motors

- Low vibration, with microstep drive, over the entire speed range

- Common driver design for the 1.8° and 0.72°/0.36° stepper motors

The driver has the following features:

- Compact and slim profile

- Compatible with pulse input line driver or open collector type pulse signals

- Easy current setting

- Equipped with protective function (alarm output)

- Expanded operating ambient temperature range

4. Characteristics of the CVK Series

4.1. Torque Characteristics

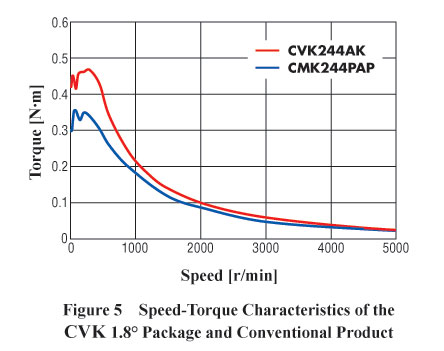

Torque characteristics are improved from the conventional DC input products. The 1.8° package employs the bipolar drive system (1) which has not been available for our conventional stepper product. For this reason, the low speed torque has been improved. The 0.72°/0.36° package employs winding specifications which focus on high speed torque.

The high speed operation quickly switches the motor winding current before the current picks up, which causes the torque to drop. To avoid this, the number of turns in a coil is reduced so that impedance is lowered and the current can pick up faster. However, the torque would decrease by reducing the number of turns in a coil. To solve this issue, the driver is built to be compatible with a large current output.

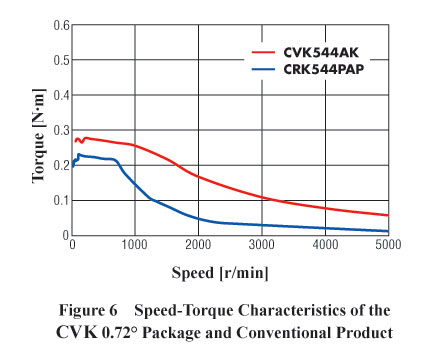

Figure 5 shows the speed-torque characteristics of the CVK 1.8° package (CVK244AK) and the conventional stepper product (CMK244-PAP). Also, Figure 6 shows the speed-torque characteristics of the CVK 0.72° package (CVK544AK) and the conventional product (CRK544PAP).

As mentioned earlier, the 1.8° stepper motor has higher torque in the low-speed range compared to the 0.72° stepper motor's, which design is focused on the high speed torque. Figure 7 shows the speed-torque characteristics of the CVK 1.8° and 0.72° stepper motors.

4.2. Vibration Characteristics

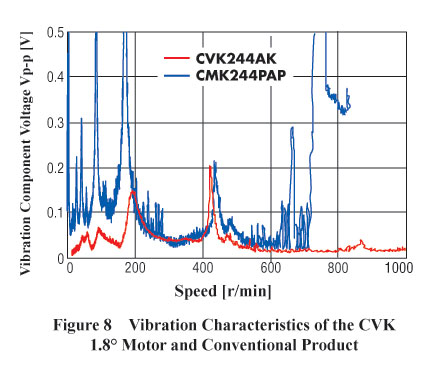

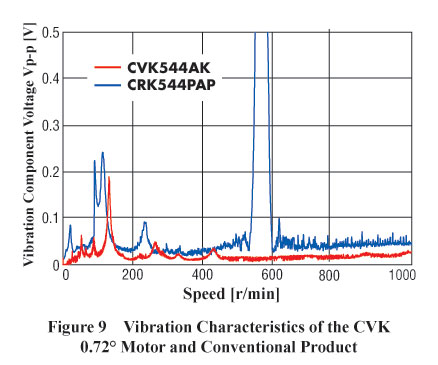

Since the stepper motor rotates in increments of a certain angle, there are cases when the vibration caused by steps becomes a problem. By utilizing the speed sensor called the DC tachogenerator, which transforms speed into voltage, the relationship between speed and speed fluctuation (Vp-p) can be indicated. Figure 8 shows the comparison between the CVK 1.8° stepper motor and the conventional stepper product. Figure 9 shows the CVK 0.72° stepper motor and the conventional stepper product.

The CVK Series operates with the microstep drive over the entire speed range and therefore, has low vibration regardless of speed. With Oriental Motor's unique smooth drive function, the operation of the speed range 0 to 50 r/min can reduce vibration. With Oriental Motor's phase correction of the current, the operation of the speed range 50 to 200 r/min can also reduce vibration. Furthermore, with the vibration suppression control built into the CVK driver, the operation of the speed range 500 r/min and above can reduce vibration. Both the 1.8° and 0.72° stepper motors successfully reduce vibration compared to the conventional stepper motor products and the vibration characteristics do not change, even when step angles are changed. This is the result of Oriental Motor’s unique microstepping control functions.

Figure 10 shows the comparison of vibration characteristics between the CVK 1.8° and 0.72° stepper motors. As indicated in the graph, the 0.72° stepper motor has lower vibration compared to the 1.8° stepper motor.

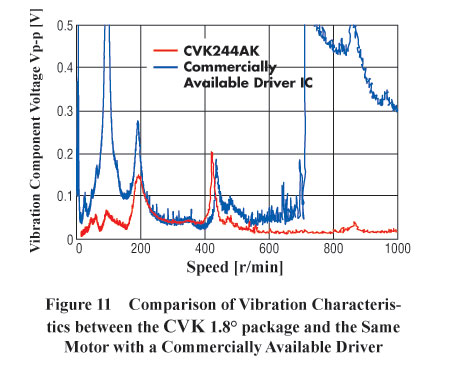

Figure 11 shows the comparison of vibration characteristics between the CVK 1.8° package and the same motor with a commercially available driver IC for stepper motors. Compared to the commercially available driver, the CVK 1.8° package has lower vibration.

4.3. Stop Position Accuracy

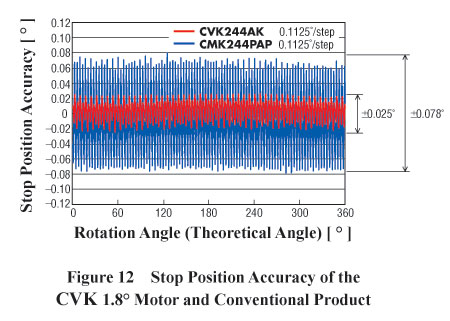

The stop position accuracy of the stepper motor is within ±0.05° at full step. During microstepping if the output current of the driver is not in a sinusoidal wave form, which has less distortion, the stop position accuracy will deteriorate compared to a full step. The driver output current wave form of the CVK Series during microstepping is more accurate compared to conventional stepper products. This results in the stop position accuracy's improvement. Figure 12 shows the stop position accuracy of the CVK 1.8° stepper motor and the conventional product (CMK 1.8° stepper motor).

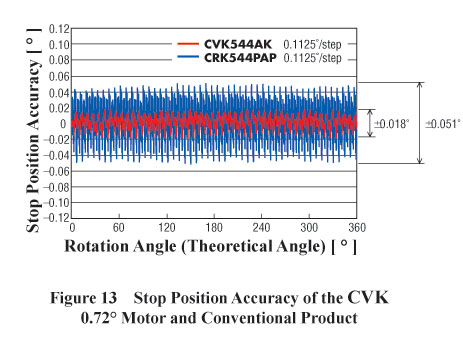

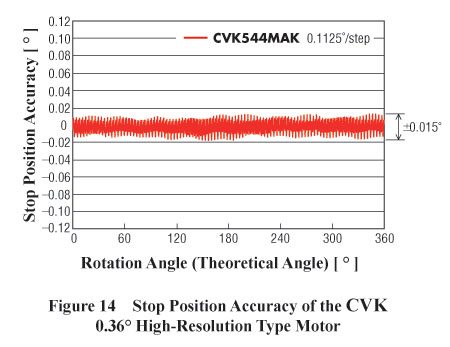

Figure 13 shows the stop position accuracy of the CVK 0.72° stepper motor and the conventional stepper product (CRK 0.72° stepper motor). Likewise, the driver output current wave form and stop position accuracy of the 0.72° stepper motor are also improved. Compared to the 1.8° stepper motor, the stop position accuracy of the 0.72° stepper motor is more accurate due to a higher number of windings. In addition to the standard type 0.72° stepper motor, the stop position accuracy of the 0.36° high-resolution type is also greatly improved. Figure 14 shows the stop position accuracy of the 0.36° high-resolution type stepper motor.

5. Features of the CVK Series Driver

5.1. Common Driver Design for the 1.8° and 0.72°/0.36° Stepper Motors

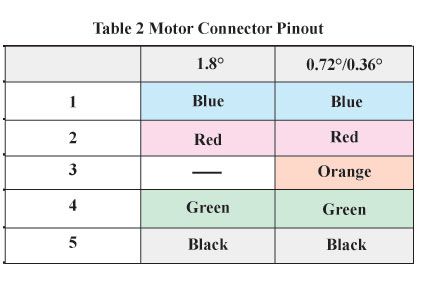

The 1.8° and 0.72°/0.36° packages share the same hardware design. Since both share the same driver functions, dimensions, connectors and I/O signal layouts, it is easy to replace one another. Table 2 indicates the motor connector pinout of the driver. The connectors for the 1.8° and 0.72°/0.36° stepper motors are common and as indicated in Table 2, each color of motor lead wires is connected with respective color.

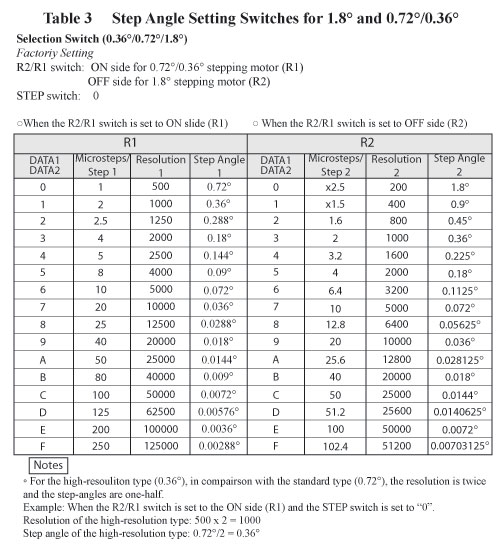

There is no need to change the wirings or pulse inputs when using both the 1.8° and 0.72°/0.36° stepper motors or to change from the 1.8° to 0.72°/0.36° stepper motor for lower vibration. In regard to step angles, both the 1.8° and 0.72°/0.36° stepper motors share the same setting switches, as indicated in Table 3.

5.2. Compact and Slim Profile

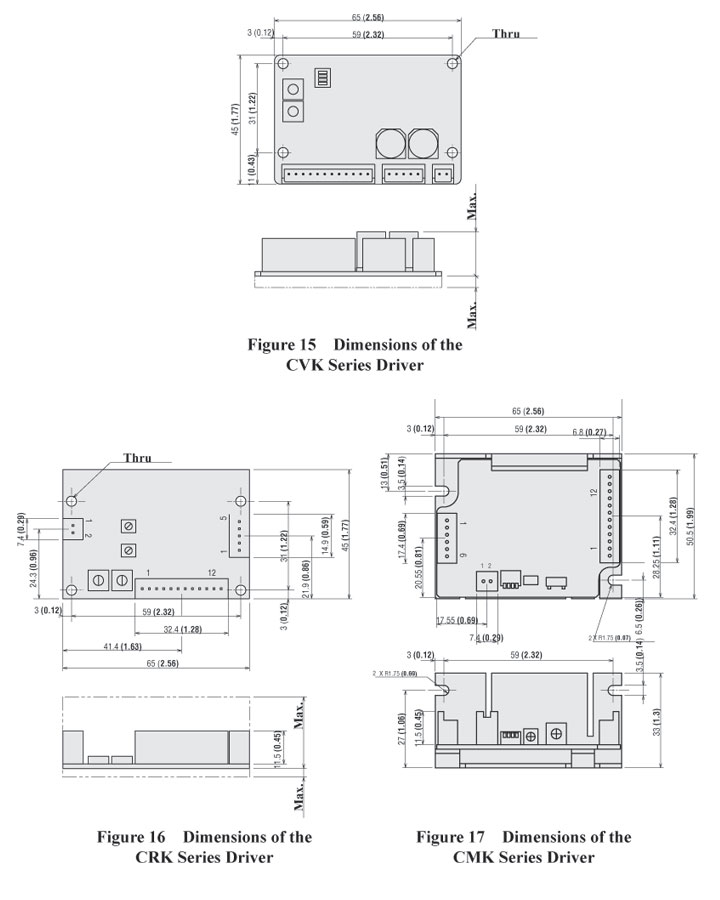

Although the driver for the CVK Series has improved characteristics compared to the conventional DC input package products, their driver frame sizes remain the same. It is thinner than the conventional stepper product (0.72°/0.36° CRK Series), which allowed for overall equipment size reduction. Figure 15 shows dimensions of the drivers for the CVK Series and Figure 16 and 17 show dimensions of the drivers for the conventional stepper products.

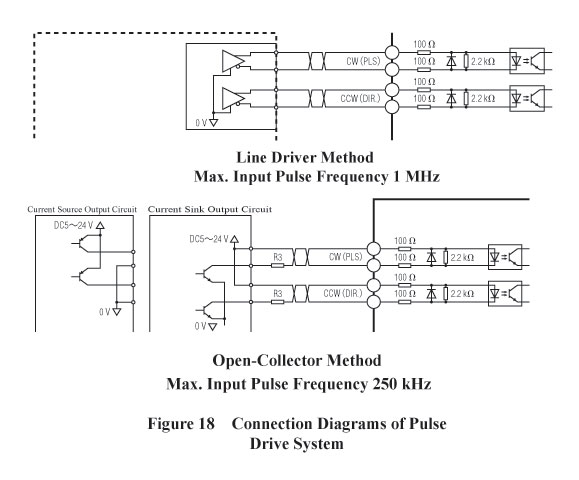

5.3. Compatible with Pulse Input Line Driver

The pulse drive system of the CVK Series driver is compatible with the line driver method, in addition to the open-collector method, which is the same as the conventional DC input package. The line driver method is capable of entering higher frequency pulses easier than that of the open-collector method and therefore, it can be operated at high speed even when high resolution is set. Also, the line driver method has better electrical noise resistance and has the advantage of being able to use the pulse line over a long distance. Figure 18 shows the connection diagrams of the pulse drive system.

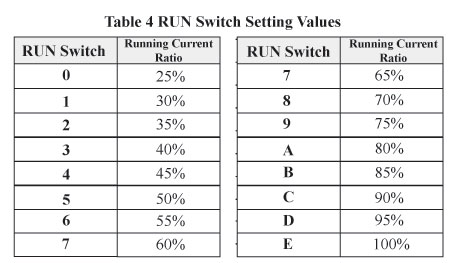

5.4. Current Setting

The CVK Series driver can easily set the motor running current with the 16-level rotary switches (RUN switch) and thus there is no need for an ammeter. When the load is light, the temperature rise in the motor can be suppressed by setting the motor running current to a lower value (reduces torque). Table 4 indicates the setting values of the RUN switch. The factory setting is the "F" mode.

The standstill current ratio can be changed by the STOP switch. The current is at 25% of the motor running current when the switch is in the OFF position and 50% when the switch is in the ON position.

5.5. Protective Function (Alarm Output)

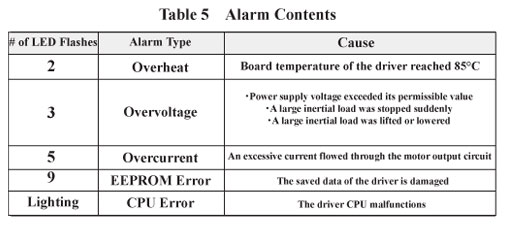

The CVK Series driver is equipped with a protective function (alarm output) that was not available for the conventional DC input package products. Abnormalities such as driver overheat, overvoltage, and overcurrent can be detected by output signals. It is possible to monitor the conditions from the host controller by using these signals. Also, when an alarm is generated, the PWR/ALM LED of the driver flashes in red and the cause that activated the protective function can be checked by counting the number of flashes on the LED. This function is convenient for checking the causes of the alarms. The motor current is stopped when an alarm is generated and thus the motor loses its holding torque. Table 5 indicates the alarm contents.

5.6. Expanded Operating Ambient

Temperature Range The ON resistance of the driver output circuit FET was reduced by approximately 1/20 of the conventional product to reduce losses. Therefore, less heat is generated even when a high current is output. Also, by having less heat generation, the upper limit of the CVK driver's operating ambient temperature range has improved from 40°C to 50°C (104°F to 122°F) (CMK driver).

6. Summary

The CVK Series not only fully utilizes the features of the 1.8° and 0.72°/0.36° motors respectively but also allows compatibility between the two. Also, it offers a wide variety of motor sizes and benefits, which can be selected depending on the application. By focusing on the ease of use of the pulse drive system, current settings, and alarm output functions for this series our engineers promoted the development of the easy-to-use products for all users. Our ultimate goal is to make the CVK Series become easier to select and use with the product line expansion in the future.