KII Series AC Motors & Gear Motors

KII Series AC Motors & Gear Motors

Oriental Motor, which has set the standard for AC motors, listened and has sought out the next generation in AC motors with the KII Series. The KII Series also offers the high strength Parallel Shaft type gears that maximize motor performance with simple wiring and flexible mounting options. The KII Series is available from 6 W (1/125 HP) up to 90 W (1/8 HP) with either Imperial or Metric standard output shafts.

- Single-Phase or Three-Phase Induction Motors, Reversible Motors and Speed Control Motors

- Parallel Shaft Gear Motors

- Imperial or Metric Shaft options

- Lead Wire or Terminal Box types

- Electromagnetic Brake type available

High Performance AC Gear Motors

Excellent Motor Performance

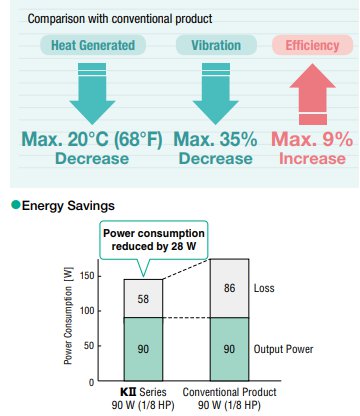

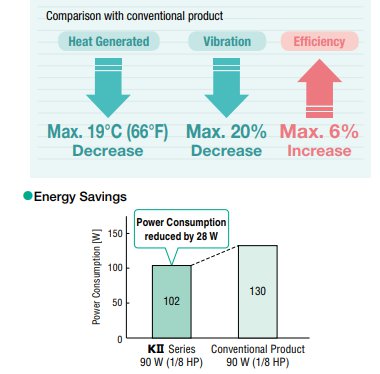

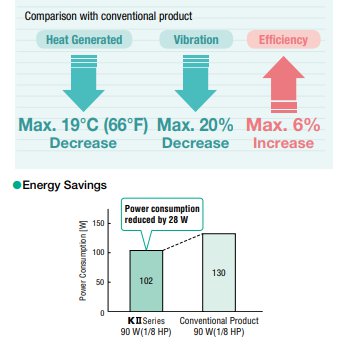

The magnetic balance for each input voltage has been re-examined and the motors have been specifically designed to optiize their characteristics.

Designing specifically for each voltage not only improves efficiency, but also contributes to equipment reliability by reducing heat and vibration generated by the motor.

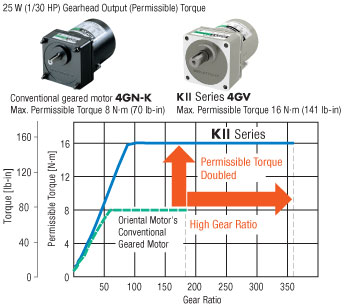

High Permissible Torque

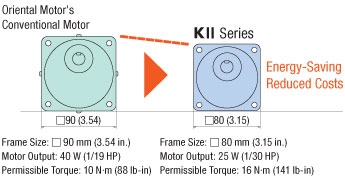

The maximum permissible torque has doubled compared to conventional products, thanks to increased gear strength* which provides a torque range that exceeds anything previously offered. Downsizing is also possible by switching the motors used in the past to the KII Series. If a small motor is selected, power consumption can be suppressed and costs can be reduced.

*Triple in 40 W products

Downsizing is possible with the same output torque.

Geared motors with twice the permissible torque compared to conventional geared motors and now with higher gear ratios.

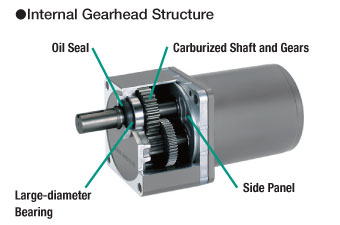

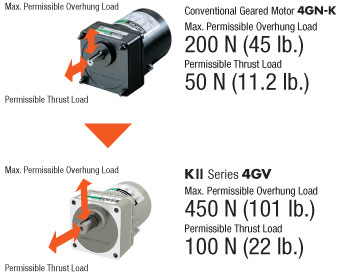

High Strength

Permissible overhung load and permissible thrust load have doubled compared to conventional products*. This has been made possible by increasing the case rigidity, adding larger diameter bearings and improved gear strength through heat treatment.

*The same in some products.

Permissible overhung load and permissible thrust load have doubled compared to conventional products. (40 W vs. 25 W comparison).

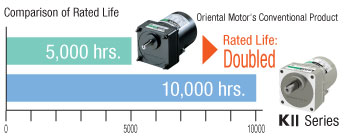

Long Life

The gearhead ball bearing diameter has increased, resulting in doubling the life of the gearhead (10,000 hours compared to the rated life of 5,000 hours for conventional gearheads). Performing maintenance has decreased as a result of the longer life.

The rated life has doubled compared to conventional products.

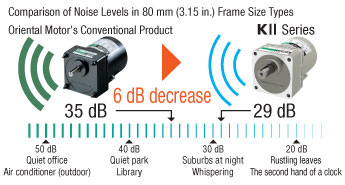

Quiet

The motor and gearhead noise (meshing sound) has decreased by approximately 6 dB compared to conventional motors. Put into perspective, the noise level has decreased by 50%.

The gearhead noise has been decreased by 6 dB compared to conventional products.

Combination Type

The motor and gearhead come pre-assembled and ready to install. Concerns of damage resulting from improper gearhead installation leading to abnormal noise in the shaft are eliminated.

Easy installation thanks to the pre-assembled motor and gearhead.

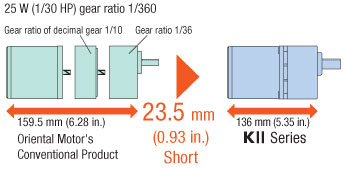

High Gear Ratio

Decimal gearheads were once required for gear ratios above 1:180. Now a single gearhead is available (up to 1:360), saving space and reducing components and costs.

No decimal gearhead is required, allowing the total length to be shortened.

Tap Output Shaft

An end tap has been integrated into the tip of the output shaft of gearheads, with a rated output power of 25 W (1/30 HP) and higher. The tap can be used to prevent pulleys and other transmission mechanisms from slipping.

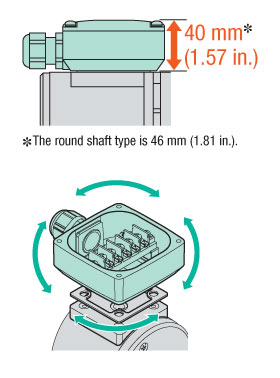

Slim Body Terminal Box Type (IP Rating)

This new shape of terminal box is designed to make wiring the terminal block easier. It has a slim body, with a cable outlet that can be rotated in 90° increments for 4 possible directions.

IP66 Compliant Drip-proof Specification

The seal structure for the motor, gearhead and terminal box components has been strengthened. The terminal box type is compliant with the IP66 degree of protection.

AC Motors & Gear Motors

Reversible AC Motors

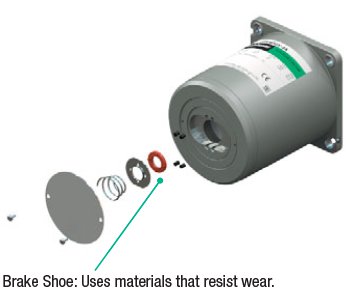

Ideal for Instantaneous Bi-Directional Operation

The motor has a built-in friction brake mechanism (friction brake) at its rear. This is ideal for the applications below.

- To repeatedly use the instantaneous bi-directional operation

- To reduce overrun

The new brake shoe with new structure experiences less aging deterioration than before.

Excellent Motor Performance

The magnetic balance for each input voltage has been re-examined and the motors have been specifically designed to optiize their characteristics.

Designing specifically for each voltage not only improves efficiency, but also contributes to equipment reliability by reducing heat and vibration generated by the motor.

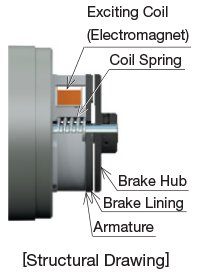

Electromagnetic Brake Type

These motors have a "power off" activated type electromagnetic brake to hold the load in position when the power is cut off.

*Available on Reversible or Three-Phase Induction Motors.

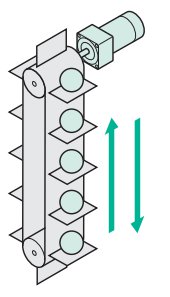

Ideal for Applications Required Load Holding

This configuration is ideal for vertical applications where the load must be held.

Power Off Activated Type Electromagnetic Brake Equipped

An AC power off activated type electromagnetic brake is equipped. When the power source is turned OFF, the motor stops instantaneously and holds the load.

Excellent Motor Performance

The magnetic balance for each input voltage has been re-examined and the motors have been specifically designed to optiize their characteristics.

Designing specifically for each voltage not only improves efficiency, but also contributes to equipment reliability by reducing heat and vibration generated by the motor.

AC Speed Control Motors

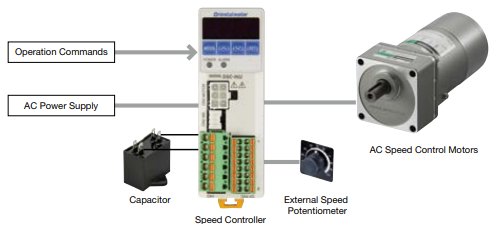

AC speed control motors are motors that include an induction motor or reversible motor equipped with a tachogenerator (AC generator) for speed detection. By combining these motors with a dedicated control circuit (speed controller), speed changes can be performed. A broad lineup of AC motors that can easily be used for speed control is available.

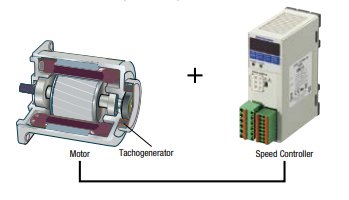

System Configuration

Driving is performed by a motor equipped with a tachogenerator (AC generator) for speed detection combined with a speed controller (control circuit).

The motor speed is set using a speed potentiometer or external DC voltage.

Structure

AC speed control motors are equipped with a tachogenerator (AC generator) on the back of the motor. The feedback signals from the tachogenerator are compared with the setting speed with the speed controller and the motor speed is adjusted.

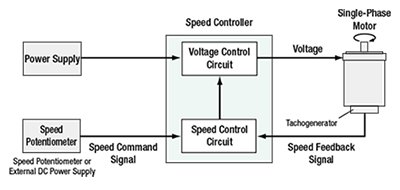

Control Block Diagram

The speed feedback signals from the tachogenerator assembled in the motor are compared with the speed command signal set with a speed potentiometer or other device in the speed controller.

The comparison result is sent to the voltage control circuit. The voltage control circuit adjusts the voltage applied to the motor and controls the motor speed.

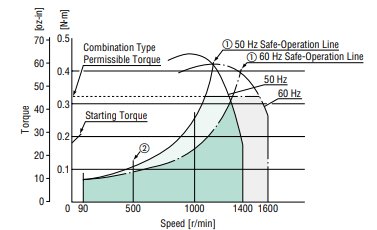

Speed - Torque Characteristics

With AC speed control motors, rated operation* is possible if operation is in the range below the safe-operation line (1) shown in the figure below.

If the load torque changes in relation to the speed set, the motor speed will also change. The speed change related to each setting speed is shown with the vertical lines (2) in the characteristics diagram.

*Induction motors have a continuous rating and reversible motors have a 30 minute rating.

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.