Brother Gearmotors Three-Phase AC Motors & Gear Motors

Brother MMD Gearmotors Three-Phase AC Motors & Gear Motors

These high efficiency ie3 new MMD AC gear motors feature superior efficiency from hypoid or helical gears while offering greater torque output thereby allowing for smaller motors and greater energy saving.

The gears in these AC gear motors are high strength, maintenance free and can be mounted in any direction with their slip fit "O" ring design. High reduction ratios, flange mount or foot mount types, right angle or hollow shaft right angle gear types available.

- ie3 Premium Efficiency (1 - 3 HP motors)

- Class F Insulation / Inverter Duty

- Brake Types Available

- Three-Phase 208/230/460 VAC

AC Gear Motor Lineup

Output Power |

Available Options |

Gear Type |

Power Supply |

Permissible Torque* |

Electromagnetic Brake |

Parallel Shaft (Foot Mount) |

Three-Phase 208/230/460 |

89 ~ 3,457 lb-in |

|

Parallel Shaft (Flange Mount) |

||||

Right-Angle Hollow Shaft |

81 ~ 2,390 lb-in |

|||

Right-Angle Solid Shaft |

85 ~ 3,819 lb-in |

|||

Electromagnetic Brake |

Parallel Shaft (Foot Mount) |

Three-Phase 208/230/460 |

124 ~ 4,751 lb-in |

|

Parallel Shaft (Flange Mount) |

||||

Right-Angle Hollow Shaft |

115 ~ 4,903 lb-in |

|||

Right-Angle Solid Shaft |

115 ~ 5,390 lb-in |

|||

Electromagnetic Brake |

Parallel Shaft (Foot Mount) |

Three-Phase 208/230/460 |

168 ~ 6,479 lb-in |

|

Parallel Shaft (Flange Mount) |

||||

Right-Angle Hollow Shaft |

159 ~ 4,903 lb-in |

|||

Right-Angle Solid Shaft |

159 ~ 6,770 lb-in |

|||

Electromagnetic Brake |

Parallel Shaft (Foot Mount) |

Three-Phase 208/230/460 |

336 ~ 10,887 lb-in |

|

Parallel Shaft (Flange Mount) |

||||

Right-Angle Hollow Shaft |

301 ~ 11,188 lb-in |

|||

Right-Angle Solid Shaft |

321 ~ 10,838 lb-in |

|||

Electromagnetic Brake |

Parallel Shaft (Foot Mount) |

Three-Phase 208/230/460 |

496 ~ 9,559 lb-in |

|

Parallel Shaft (Flange Mount) |

||||

Right-Angle Hollow Shaft |

451 ~ 10,232 lb-in |

|||

Right-Angle Solid Shaft |

468 ~ 10,751 lb-in |

*Torque and Speed vary based on input voltage and frequency, please review product specifications for details.

ie3 Premium Efficiency Gear Motors (1 - 3 HP Motors) Saves Significant Operating Costs

MMD Motor

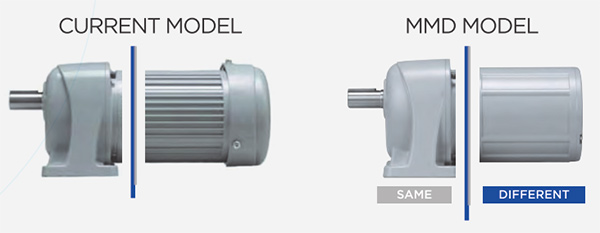

Introducing the new Modular Mid Design (MMD) motors from Brother. The MMD gearmotors now feature a more compact design with the same hypoid and helical gearheads. This means, same mounting in a more compact design.

The new ie3 premium efficiency gear motors cost less to operate and demonstrate clear benefits when running for long periods of time (when compared to ie1 standard efficiency gear motors).

Benefits of using Premium Efficiency ie3 motor when compared to standard ie3 motor:

- Helps improve overall plant efficiency by reducing energy costs

- Helps increase ROI and long term savings

- Minimizes maintenance and helps improve overall operations

- Helps increase flexibility due to the wide speed range (stock reduction)

- Produces less noise and runs cooler with less mechanical stresses

- Environmentally friendly-RoHS compliant

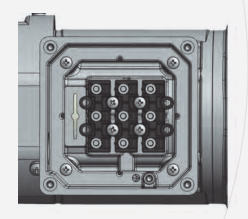

More Clearance for Wiring

Revised dimensions and terminal block layout. The new design allows for more working space when wiring.

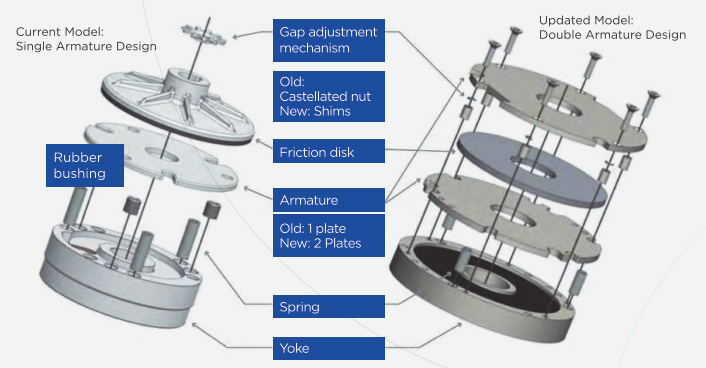

New Multi-Layer Brake Mechanism

Energy Efficient

Reduces brake power consumption by up to 40% compared to the current model.

Note: Results may vary between motor sizes.

Stable Braking Torque

Increased torque stability from the initial stage of operation compared to the current model.

High Efficiency Gear Motors

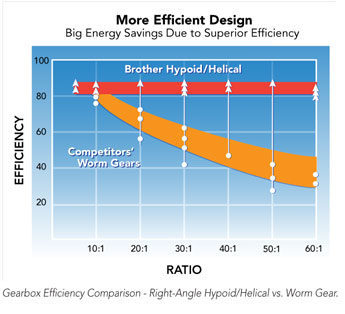

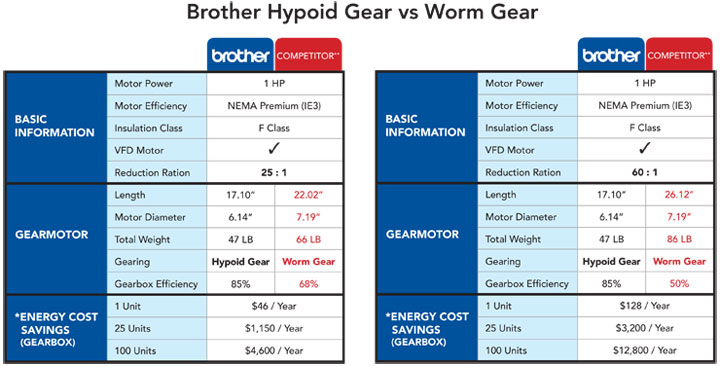

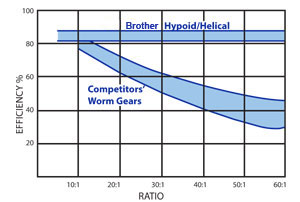

High efficiency gear motors feature Hypoid gearing technology that can maintain efficiency above 85% throughout the motor's wide speed range. Compared to commonly used worm gears' lower efficiency, this can result in massive energy savings. Lower cost to operate - applications running for long periods will demonstrate clear benefits.

The ie3 gear motors have a wide speed range that does not suffer in efficiency from the motor or gearbox. These gear motors can be mounted in any direction because they are sealed for life with grease.

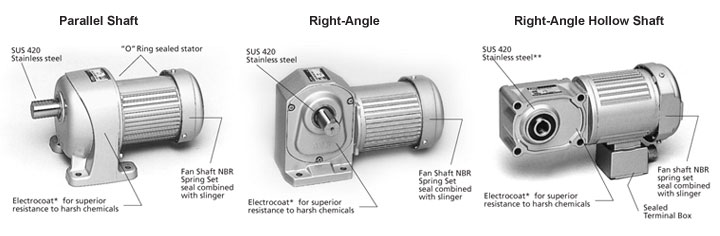

Electrocoat Paint

The ie3 gear motors also feature an acrylic Electrocoat paint that provides total coverage of the gearmotor. Similar to how the frames of cars are painted, each individual outer facing part is completely dipped in electrically charged paint. This offers complete coverage of the outer body which helps prevent cleaners from penetrating and chipping paint. This acrylic paint also has a higher level of hardness which will avoid scratches and scrapes from chipping the paint. Lastly, the paint is FDA approved to have incidental food contact specifications.

IP65 Type

The ie3 gear motors have been made to withstand harsh environments. Available IP-65 ratings allow these gearmotors to be cleaned with cleansers for sanitation without affecting the motors' performance.

High Torque AC Gear Motors

These high torque AC gear motors offer superior efficiency by using Helical and Hypoid gears making it possible to replace spur and worm gearbox/motor combinations with smaller HP AC gear motors and actually receive greater torque at the driven shaft. With smaller motor HP required less electrical current is needed, resulting in lower energy costs.

Three Gear Types are Available:

Parallel Shaft (Inline) |

Right-Angle |

Right-Angle Hollow Shaft |

|

|

|

|

||

IP65 Types Available

IP65 washdown AC gear motors offer superior resistance to water ingress and harsh environments used in food processing plants.

- Stainless steel shaft

- Helps protect against pressure jets of water

- Helps protect against dust and harsh environments

- Terminal Boxes are specially designed, sealed and gasketed. Complete with stainless steel IP65 cord grip.

Brake Types Available

The brake system for these AC gear motors uses vibration damping sheet steel for the armature, which dramatically reduces noise associated with the brake.

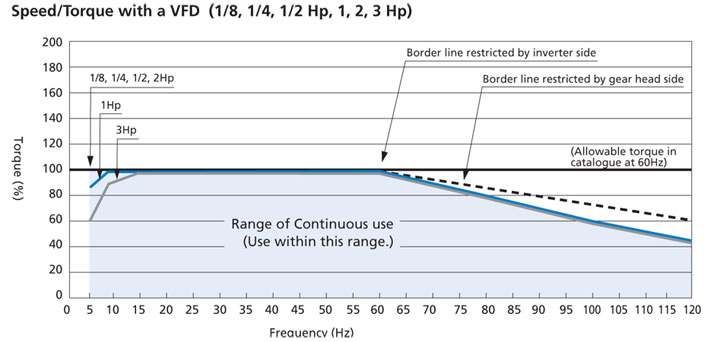

Performance Examples with Third-party Inverter

Parallel Shaft AC Gear Motor - Brother Gearmotors Helical Gearing (G3 Series)

Lightweight and Compact

Die cast aluminum gear housings and motors make these AC gear motors and reducers light in weight, allowing engineers to design more economical mounting provisions.

Longer Life

Compared to a spur gear of approximately the same pitch diameter, Helical gears can transfer high loads at greater speeds. This is due to the gradual engagement of the teeth and smooth transfer of the load.

Maintenance Free

High-quality synthetic grease is used in all gearboxes. They are filled at the factory and do not require maintenance filling or level checks. This saves valuable time at set up and eliminates concern for costly oil disposal required by the EPA.

High Durability Finish

Electrocoat paint is standard for these AC gear motors and provides higher durability and superior resistance vs. traditional painting or powder coat finishes and can also be considered for harsher environments.

Mount in Any Direction

These gearboxes are sealed with machine "slip" fit "O" rings and double lip spring shaft seals on both the motor and input shaft and output shaft driver. Thus, the gear motors can be mounted in any conceivable direction without concern for the position of a breather plug.

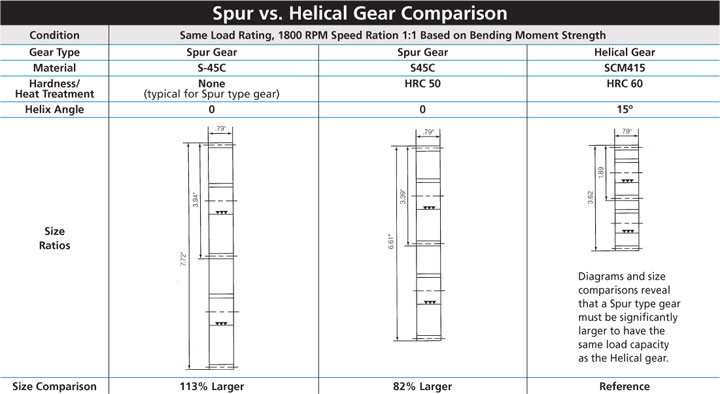

Spur vs. Helical Gear

These motors feature Helical Gears made of chromium molybdenum steel that has undergone precision carbonitriding. These Helical Gears outperform common spur gears.

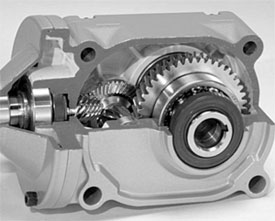

Right-Angle Hollow Shaft AC Gear Motor - Brother Gearmotors Hypoid / Helical Gearing (F3 Series)

More Efficient / Longer Lasting

Hypoid gearing is up to 80% more efficient than worm gears. The all steel Hypoid/Helical combination had much better wear properties than softer bronze worm gearing and last longer and run cooler than worm gears.

High Reductions / Small Size

Gear reductions up to 1500:1 are available in most sizes. Hypoid gearing makes the high reduction significantly more compact and lightweight compared to worm/worm and helical/worm designs.

Mount in Any Direction

These gearboxes are sealed with machine "slip" fit "O" rings and double lip spring shaft seals on both the motor and input shaft and output shaft driver. Thus, these gear motors can be mounted in any conceivable direction without concern for the position of a breather plug.

High Durability Finish

Electrocoat paint is standard for these gear motors and provides higher durability and superior resistance vs. traditional painting or powder coat finishes and can also be considered for harsher environments.

Maintenance Free

High-quality synthetic grease is used in all gearboxes. They are filled at the factory and do not require maintenance filling or level checks. This saves valuable time at set up and eliminates concern for costly oil disposal required by the EPA.

Hypoid Gearing

Hypoid Gears are made of chromium molybdenum steel that has undergone precision carbonitriding. The superior efficiency, gear materials and heat treatment allows engineers to design-in the most compact gearmotor per output torque. These unique right-angle type gear motors have much higher power transmission efficiency than conventional worm gears. Growing demand is due to its COMPACTNESS, HIGH EFFICIENCY, and superior wear life, which meet the latest primary requirements for industrial applications.

Right-Angle AC Gear Motor - Brother Gearmotors Hypoid Gearing (H2 Series)

Longer Life

Hypoid gear motors and reducers use hardened steel gears throughout. This give Hypoid gearing far superior wear life compared to worm gears which use softer bronze on the output gear.

High Reductions / Small Size

Gear reductions up to 1200:1 are available in most sizes. Hypoid gearing makes the high reduction significantly more compact and lightweight compared to worm/worm and helical/worm designs.

Mount in Any Direction

These gearboxes are sealed with machine "slip" fit "O" rings and double lip spring shaft seals on both the motor and input shaft and output shaft driver. Thus, the gear motors can be mounted in any conceivable direction without concern for the position of a breather plug.

High Durability Finish

Electrocoat paint is standard for these gear motors and provides higher durability and superior resistance vs. traditional painting or powder coat finishes and can also be considered for harsher environments.

Maintenance Free

High-quality synthetic grease is used in all gearboxes. They are filled at the factory and do not require maintenance filling or level checks. This saves valuable time at set up and eliminates concern for costly oil disposal required by the EPA.

Hypoid Gearing

Hypoid Gears are made of chromium molybdenum steel that has undergone precision carbonitriding The superior efficiency, gear materials and heat treatment allows engineers to design-in the most compact gearmotor per output torque. These unique right-angle type gear motors have much higher power transmission efficiency than conventional worm gears. Growing demand is due to its COMPACTNESS, HIGH EFFICIENCY, and superior wear life, which meet the latest primary requirements for industrial applications.

Inverter / VFD

With its high functionality, compact design, simple operation, with built-in network capabilities and global compatibility, the new FRENIC-Mini (C2) elevates the performance of a wide range of devices and equipment--including conveyors, fans, pumps, centrifugal separators, and food processing machines--to give you the system integration, energy efficiency, reduced labor, and lower overall costs you're looking for.

- Single-Phase 115 VAC or 230 VAC input, Three-Phase 230 VAC or Three-Phase 460 VAC input.

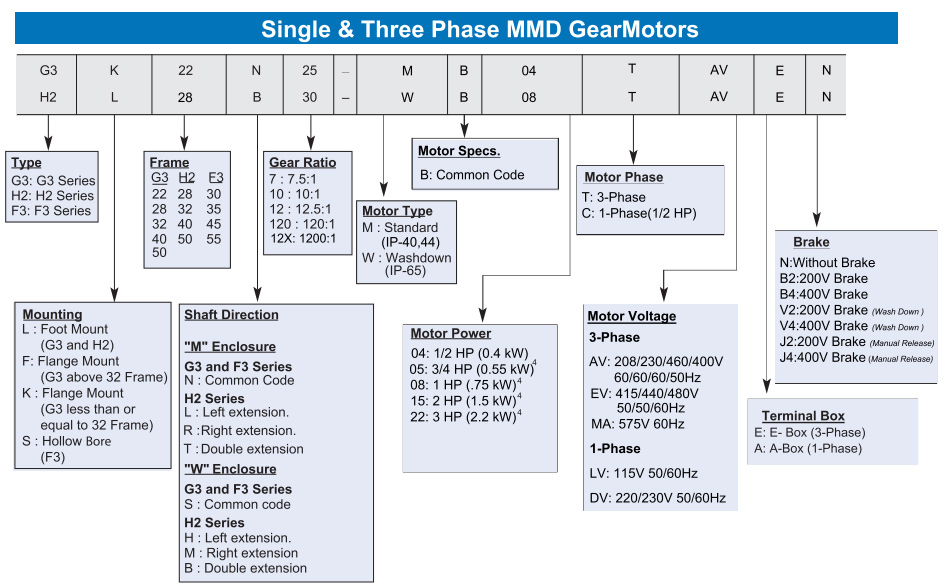

Part Number Code

*Products ending in "X" are specials. Contact your original supplier for details.

CAD / Manual Search

To locate product CAD and Operator Manuals please search using the product Item Number.