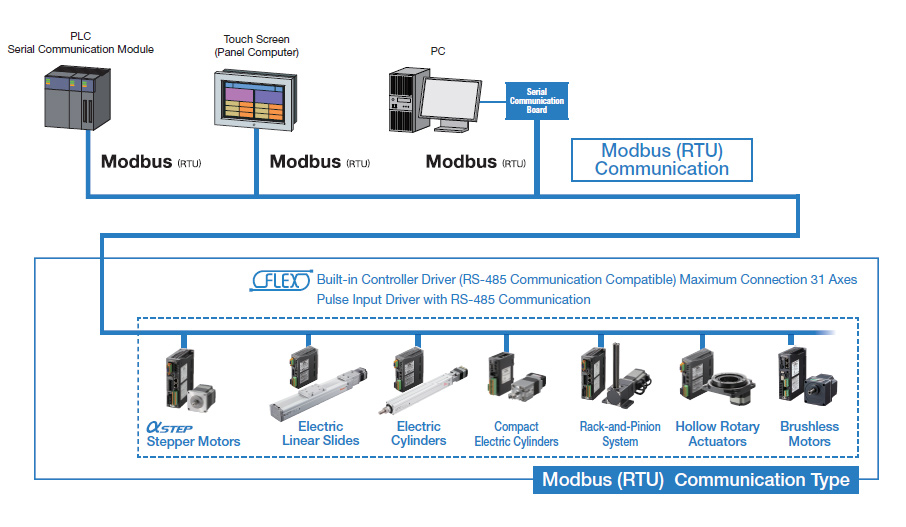

Modbus (RTU) Network Products

Modbus is the open field network with Modbus Protocol installed. Modbus is used widely in field of factory and process automation because its protocol specification is open to the public and it is very simple.

- Up to 31 axes can be connected to a single programmable controller (master equipment)

- PC can control the motor

- Maintenance from the touch screen is possible

Motor control via Modbus (RTU) communication can detect the status of the motor/actuator directly by data. This results in a shorter development period and increased reliability and service live of the equipment. Modbus (RTU) communication you can simplify siring, reduce man-hours and improve maintenance and performance.

Modbus is a registered trademark of Schneider Automation Inc.

Configuration

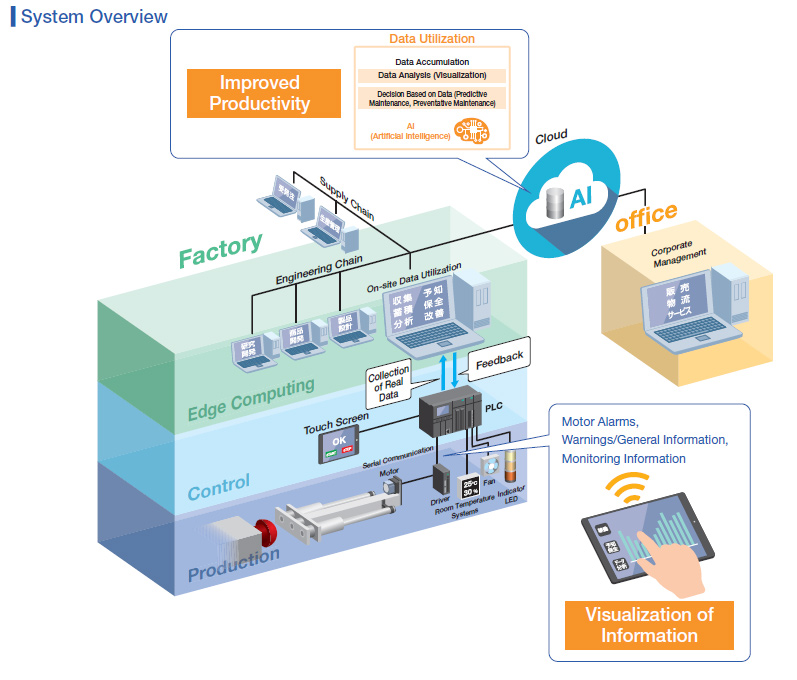

Contributes to Analysis of Conditions

Increased productivity is sought in manufacturing plants. At the same time, it is imperative to continue utilizing the knowledge of human experience through the use of Artifi cial Intelligence (AI). In order to use AI, it is important to collect, digitize and analyze the day to day “changes in conditions". Oriental Motor has created a wide lineup of products capable of outputting the various changes in conditions of motors.

Predictive Maintenance Using IoT (Internet of Things)

In order to detect early signs of failure, it is important to monitor changes in operating conditions daily. One way to do this is to visualize position displacement due to fluctuation in temperature and operation time. This video demonstrates how the AZ Series works with an IoT setup to continuously monitor feedback information. Using this information, overall health of components can determined and manufacturing and productivity can be improved.

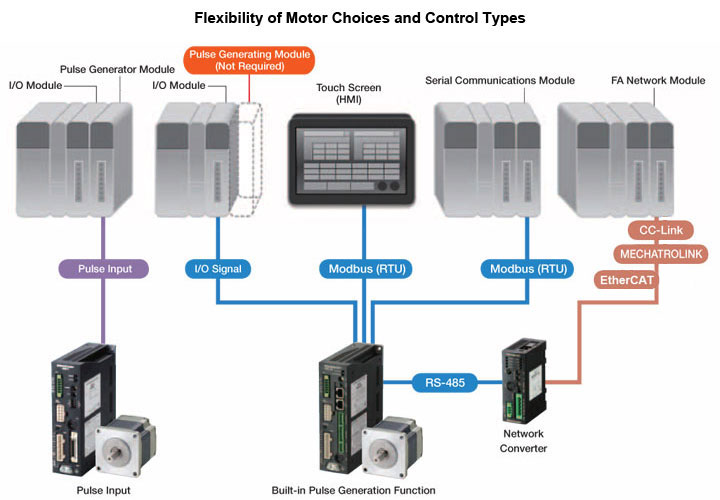

Industrial Network Communication for Automation and Motion Control

Oriental Motor offers industrial network communication products under the FLEX concept, meaning each product is equipped with an interface that connects to various industrial networks and master controllers featuring I/O; such as PLC, HMI or serial communication such as RS-485 / Modbus (RTU).

FLEX is the generic name for products that are used for Factory Automation (FA) network control via I/O control, Modbus (RTU) control, or a network converter. FLEX products enable easy connection, easy control, and reduce the complexity of system configuration.

The Advantages of FLEX Industrial Network Communication Products

- Simple Wiring

- Energy Saving

- Time Saving

- Low Cost

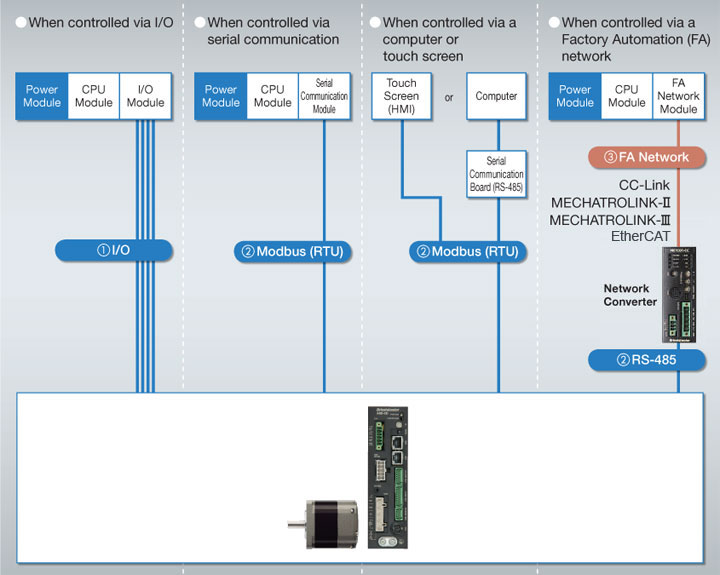

Built-In Controller (Stored Data type)

Operating data is set in the driver and the operating data is selected and executed from the master controller. Connection and control with the master controller is done through either:

- I/O

- MODBUS (RTU) / RS-485

- Factory Automation (FA) network

1. I/OThe functions of a positioning module (pulse generator) are built into the driver allowing it to be connected directly to a controller or PLC to configure an operating system with I/O. Since no positioning module is required on the PLC side, space is saved and the system is simplified. |

2. Modbus (RTU) / RS-485Operating data, parameter settings or operation commands can be input via RS-485 communication. A maximum of 31 drivers can be connected to one serial communication module. There is also a function for simultaneously starting multiple axis. The protocol is compatible with Modbus (RTU) and can be connected to a touch screen (HMI), PC, etc. |

3. Factory Automation (FA) NetworkBy using a network converter (sold separately), CC-link or MECHATROLINK communication are possible. Operating data, parameter settings or operation commands can be easily input. |

I/O Control

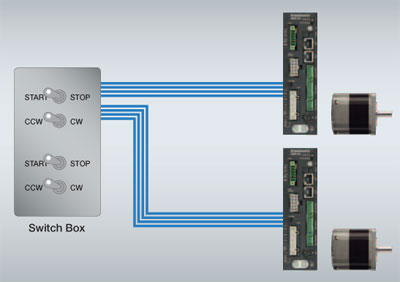

I/O Control via Switches

Since operating data is set in the driver, the motor can start and stop with hand switches.

Easy control without the use of a PLC is possible.

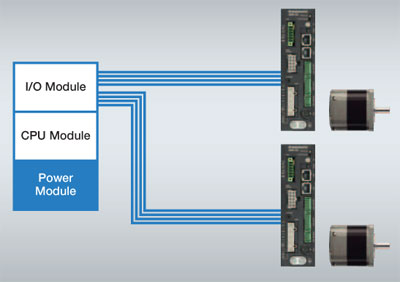

I/O Control via PLC (Positioning module not required)

Operating data is set in the driver, allowing it to be connected directly to a PLC to select the motion profile. Since no positioning module is require on the PLC side, space is saved and the system is simplified.

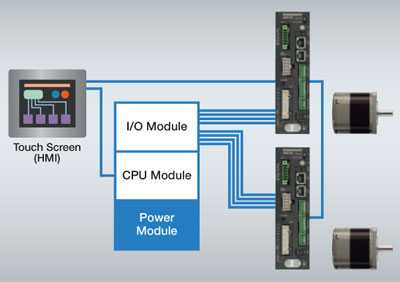

I/O Control via PLC, Traveling Distance and Speed Setting Operated via Touch Screen (HMI)

The motor normally starts and stops via I/O, and Modbus (RTU) communication is used when setting the alarm and operating data.

Setting changes as well as monitor and alarm displays are performed on the touch screen.

If multiple configurations exist, parameters can be entered on the touch screen, reducing the burden of combining programs or sequences.

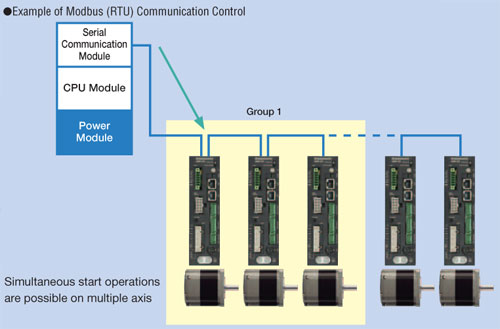

2. Modbus (RTU) Control

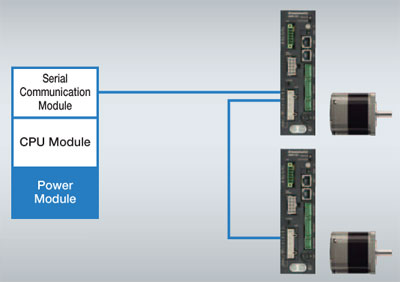

Modbus (RTU) Control via PLC

Operating data, parameter settings or operation commands can be input via RS-485 communication.

A maximum of 31 drivers can be connected to one serial communication module. There is also a group sending function for simultaneously starting multiple axis. The protocol is compatible with Modbus (RTU) and can be easily controlled via PLC, etc.

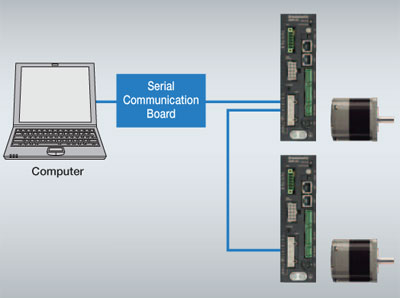

Modbus (RTU) Control via PC

Operating data, parameter settings or operation commands can be input by inserting it into an RS-485 communication board on a PC. No changes are required to your serial communications board.

Simple Connection with a Touch Screen (HMI)

By using Modbus (RTU) communication, connection can be made directly to a touch screen (HMI).

Operating data, parameter settings, alarm history, test drive, etc. can be used, allowing the motor to be controlled without the added cost of a PLC or computer.

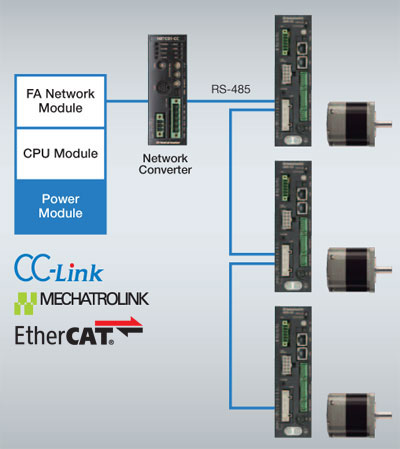

3. Factory Automation (FA) Network Connection via a Network Converter

CC-Link Control / MECHATROLINK Control / EtherCat Control

By using a network converter (sold separately), CC-link communication, MECHATROLINK communication and EtherCat communication are possible. Operating data, parameter settings or operation commands can be input via various types of communication. Since it can flexibly accommodate the networks specified by the end user, design time is shortened.

- The burden on the programmable master controller is reduced and costs are lowered when multiple axis are used.

- Compatible with various networks, allows for multiple axis or additional axis if needed.

- CC-Link compatibility: Max. 12 axis

- MECHATROLINK-II compatibility: Max. 16 axis

- MECHATROLINK-III compatibility: Max. 16 axis

- EtherCat compatibility: Max. 16 axis

- Can also handle group sending function between groups

Function Introduction

Group Sending Function

This function simultaneously starts multiple axis in Modbus (RTU) communication and the Factory Automation (FA) network. Multiple drivers are grouped together, and when operation commands are sent to that group's parent, all of the drivers belonging to the same group are operated.

- Modbus (RTU) control: Handles simultaneous starting, changes in distance, velocity and monitoring

- Factory Automation (FA) network control: Only simultaneous starting.

Modbus (RTU) Compatible Products

![]() Products that can be connected to Modbus (RTU) communication.

Products that can be connected to Modbus (RTU) communication.

*Network compatible drivers required for network communication.

αSTEP AZ Series Stepper Motors with Mechanical Absolute Encoder

The αSTEP AZ Series stepper motors offer high efficiency, low vibration and incorporates our newly developed Mechanical Absolute Encoder for absolute-type positioning without battery back-up or external sensors to buy. Closed loop performance without hunting or gain tuning. Available with a built-in controller or pulse input driver which substantially reduces heat generation from the motor through the use of high-efficiency technology. Requires αSTEP AZ Series Driver.

- Battery-Free, Mechanical Absolute Encoder Stepper Motors

- Closed Loop Performance, No Hunting or Gain Tuning

- AC or DC Input Types

- Parallel Shaft and Right Angle Geared Types for Higher Torque, Space Savings

- Electromagnetic Brake Type Available

- αSTEP AZ Series Stepper Motor Driver Required*

αSTEP AZ Series Linear Actuators

Motors offer excellent controllability and are therefore used as the drive sources of various automated equipment. In many cases a motor is combines with various mechanical components such as a ball screw, belt and pulley, and rack and pinion to convert the motor rotation to a different type of motion needed to drive the equipment. Oriental Motor has various linear actuators consisting of a motor assembled with the necessary mechanical components to meet the various needs of automated equipment.

- Electric Slides, Electric Cylinders, Compact Linear Actuators, Electric Grippers and Rack-and-Pinion Systems

- Battery-Free, Mechanical Absolute Encoder Stepper Motors

- AC or DC Input Types

- Electromagnetic Brake Type Available

- αSTEP AZ Series Stepper Motor Driver Required*

αSTEP Closed Loop AZ Series Absolute Encoder Hollow Rotary Actuators

The DGII Series is a line of of products that combine a high rigidity hollow rotary table with an αSTEP absolute encoder AZ series closed loop stepper motor and driver package. It retains the ease of use of a stepper motor, while also allowing for highly accurate positioning of large inertia loads.

- Integrated actuator and stepper motor makes design easier

- Vertical or Horizontal Mount Motor Types

- Easy Home Setting and Return-to-Home without need for sensors

- Large-diameter hollow output table

- AC or DC Input

- αSTEP AZ Series Stepper Motor Driver Required*

OVR Series Robots and Controllers

The OVR Series offers Articulated 4-axis, 5-axis, and 6-axis small horizontal transport robots, SCARA robots and Cartesian robots with a simple mechanism that can be easily controlled and constructed cost-effectively. Control with the MRC Series controller and AZ Series motor drivers.

- Articulated, SCARA and Cartesian / Gantry Robot are available

- Transportable mass 1 ~ 5 kg

- Compact and lightweight

- Control with the MRC Series controller and AZ Series motor drivers

AZX Series Battery Free Absolute Encoder Servo Motors

These servo motors are equipped with a battery-free absolute encoder. They are suitable for continuous speed control or positioning applications with a large amount of travel since they achieve high torque in the high speed range. The basic operations are the same as the AZ Series, making combined use of equipment easy.

- Compact and High Power

- Wide Variable Speed Range

- Standard or Planetary Geared Type

- Electromagnetic Brake Types

- AZX Series Driver Required*

Stepper Motors

A stepper motor is used to achieve precise positioning via digital control. The motor operates by accurately synchronizing with the pulse signal output from the controller to the driver. Stepper motors, with their ability to produce high torque at a low speed while minimizing vibration, are ideal for applications requiring quick positioning over a short distance.

- 0.79 in. ~ 3.54 in. (20 mm~ 90 mm) NEMA 8 ~ NEMA 34 frame size stepper motors

- Non-backlash, Low-backlash and Spur Gears available

- 2-Phase Stepper Motors and 5-Phase Stepper Motors

- Encoder and Electromagnetic Brake Options

Brushless DC Motors (BLDC Motors) & Gear Motors

Brushless DC motors offer high torque and stable speed control combined with a space savings design contribute to a compact and powerful solution. With their flat torque, can produce rated torque from low to high speeds easily.

- 15 W up to 400 W

- DC or AC Input

- Geared and Electromagnetic Brake Options

ROS Support

The Robot Operating System (ROS) is a set of software libraries and tools that help you build robot applications. Modbus RTU device control can be achieved simply by distributing ROS messages. Use this material to simplify setup between ROS and a Modbus RTU node.

*Please prepare the conversion cable necessary for connecting the ROS main unit and the PC.

*This document is intended for those with ROS and Linux expertise. Inquiries about installing and using ROS and Linux are not supported.

You can download ROS nodes, manuals and sample code.

Network Type |

Function |

Compatible Drivers |

Download |

|---|---|---|---|

Modbus (RTU) |

|

BLE series RS-485 communication type |

|

BLH series RS-485 communication type |

|||

BLV series |

|||

BLV series R type |

|||

AZ series built-in controller type with RS-485 Communication |

|||

AZ series mini driver DC power input |

|||

AR series built-in controller type |

|||

RKII series built-in controller type |

|||

CVD series RS-485 communication type |

*Some of these drivers are also used with our linear and rotary electric actuators, such as the EZS Series and DGII Series.

ROS Operating Environment

Target OS: Ubuntu 20.04 LTS (Linux)

ROS distribution: Noetic Ninjemys

ROS version: 1.15.14

ROS2 Operating Environment

Target OS: Ubuntu 22.04 LTS (Linux)

ROS distribution: Humble Hawksbill

Business Hours:

Monday to Friday

8:30am EST to 5:00pm PST

Sales & Customer Service:

1-800-418-7903

Technical Support:

1-800-GO-VEXTA (468-3982)