5-Phase Stepper Motor Drivers

RKII Series 5-Phase Stepper Motor Drivers (AC Input)

The RKII Series stepper motor driver is a high performance, energy saving stepper motor driver with a great low price. To achieve constant maximum torque output with low heat generation and save energy, the stepper motor and driver losses have been substantially reduced allowing to be operated for longer hours at high speed, which is not possible with conventional stepper motors and drivers. With simple wiring featuring screw-less connectors and side by side driver mounting, installation is easy and saves space.

- High Efficiency, Low Vibration, Microstepping Stepper Motor Driver

- Stored Data (Network Compatible) Type or Pulse Input Type (use step angle switch to accept 1.8° pulse signals)

- Built-in Protective Functions

- Single-Phase 100-120 or Single-Phase 200-240 VAC

CVD 5-Phase Stepper Motor Drivers (DC Input)

The CVD 5-phase stepper motor driver offers superior performance and value and is ideal for OEM or single axis machines. The CVD stepper motor drivers offer:

- Lowest Vibration and Noise with advanced Microstepping control

- Pulse Input, RS-485 Communication, Fully Closed-Loop or Speed Control Types

- Significantly improves positional accuracy when microstepping

- Small, thin microstepping drive with space saving FETs

- Selectable step angle and microstepping filter control

- Alarms

- 24 VDC Input

- 0.35 ~ 3.8 A/Phase

CVD 2-Phase / 5-Phase Stepper Motor Multi-Axis Drivers (DC Input)

This compact, lightweight 4-axis control CVD driver reduces wiring and saves valuable space. The Multi-Axis Type CVD Series stepper motor drivers offer:

- Wiring for communication, power supply, etc., for the 4-axis, are integrated into a single-driver

- Can be used with 2-phase/5-phase stepper motors

- EtherCAT communication enables synchronous operation

- Automatically controls electromagnetic brakes using data acquired from integrated encoders, which can reduce host controller costs and program creation time

- 2 connector types options

- Alarms

- 24 VDC Input / 0.3 ~ 2.8 A/Phase

CVK Series Speed Control Stepper Motors & Drivers

The CVK Series SC speed control system offers a simple configuration consisting of a stepper motor, driver and programmable controller. The operating speed, acceleration and deceleration time, running current can be set via the driver switches, and simply turning the FWD (RVS) input to ON or OFF allows for easy control.

- No pulse generator needed

- 2 speed settings are possible

- Compact and high torque stepper motor

Types of Stepper Motor Drivers

Drivers that operate in the pulse input mode and built-in controller mode are available. You can select a desired combination according to the required operation system.

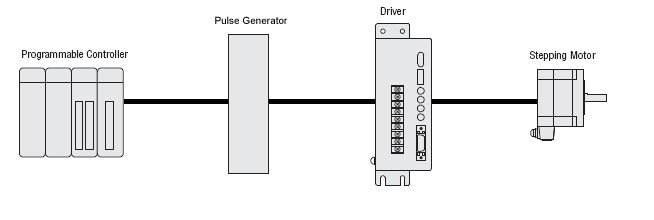

Pulse Input Drivers

The stepper motor can be controlled using a pulse generator provided by the user. Operation data is input to the pulse generator beforehand. The user then selects the operation data on the host programmable controller, then inputs the operation command.

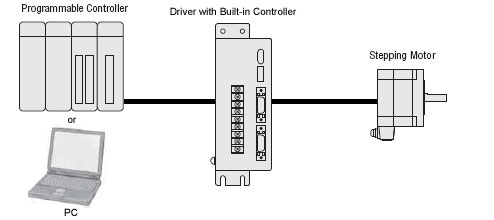

Built-in Controller (Stored Data or Stored Program) Type Drivers

The built-in pulse generation function allows the motor to be driven via a directly connected personal computer or programmable controller. Since no separate pulse generator is required, drivers of this type save space and simplify wiring.

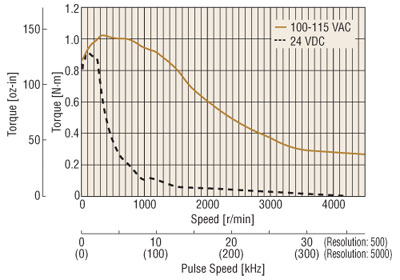

Difference Between AC Input and DC Input Characteristics

A stepper motor is driven by a DC voltage applied through a driver. In Oriental Motor's 24 VDC input motor and driver systems, 24 VDC is applied to the motor. In the 100-115 VAC motor and driver systems, the input is rectified to DC and then approximately 140 VDC is applied to the motor (certain products are exceptions to this.)

This difference in voltage applied to the motors appears as a difference in torque characteristics at high speeds. This is due to the fact that the higher the applied voltage is, the faster the current rise through the motor windings will be, facilitating the application of rated current at higher speeds. Thus, the AC input motor and driver system has superior torque characteristics over a wide speed range, from low to high speeds, offering a large speed ratio.

It is recommended that AC input motor and driver systems, which are compatible over a wider range of operating conditions than DC input systems, be considered for your application.

5-Phase Stepper Motor Product Comparison

Product Series |

||

|

|

|

|

Features |

Improved Performance Accuracy |

High Resolution |

Basic Step Angle |

0.72° |

0.72°, 0.36° |

Driver Power Input |

AC |

DC |

Frame Sizes |

1.65 in. (42 mm) NEMA 17 |

0.79 in. (20 mm) NEMA 8 |

Available Options |

Geared Type |

Geared Type |

Max. Holding Torque |

19.8 oz-in up to 460 lb-in |

3.2 oz-in up to 70 lb-in |

0.14 N·m up to 52 N·m |

0.0231 N·m up to 8 N·m |

|

Learn More |